Combined butterfly valve

A combination and butterfly valve technology, applied in the direction of lifting valve, valve details, valve device, etc., can solve problems such as troublesome, difficult to guarantee the reserved length and size of the pipeline, and difficult to guarantee the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

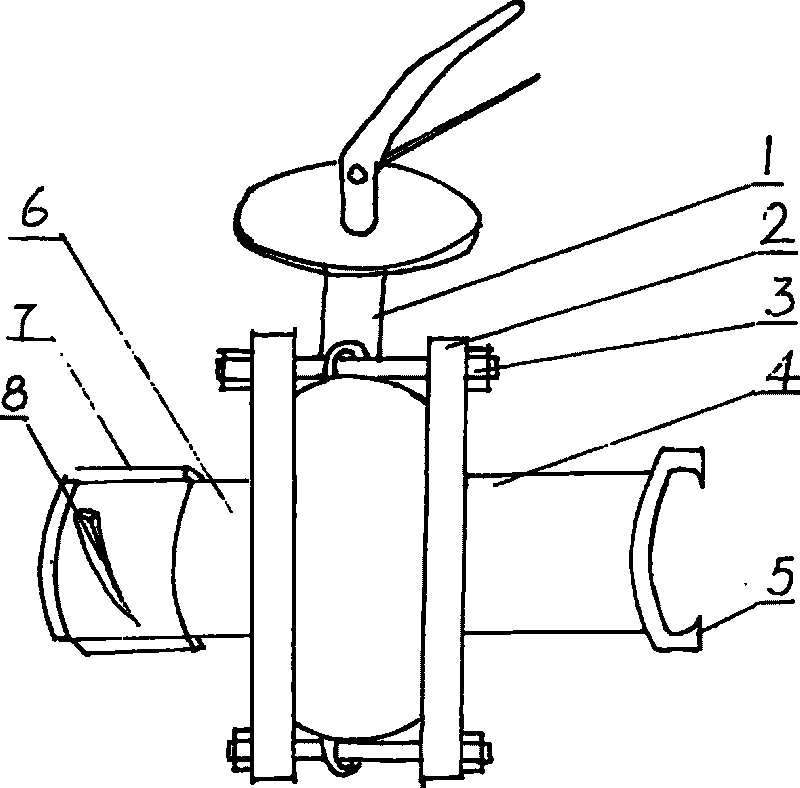

[0010] Such as figure 1 As shown, the present invention includes a butterfly valve body 1 and joints 4, 6. A flange 2 is provided on both sides of the butterfly valve body, and one side of the flange is fixedly connected to the joint. The joint is set according to needs and can be a male joint. 4. It can also be a female connector 6. The said male joint is fixedly connected with cat claws 5 on the outer end surface of the short tube, and the number of cat claws is determined according to the needs, which are generally arranged symmetrically, and can also be arranged equidistantly. In this embodiment, two symmetrical arrangements are selected, and the said The female joint of the short pipe is provided with an "O" type seal ring groove at the outer end of the short pipe, so as to be plugged with the seal ring, and a differential sliding sleeve 7 is set on the short pipe. There are spiral protrusions 8 on the outside of the differential sliding sleeve. The spiral protrusions ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com