Linear rolling bearing having bonded rolling surface components

A technology of linear rolling bearings and rolling surfaces, which is applied in the direction of anti-centrifugal rotating parts, linear motion bearings, bearings, etc., can solve the problems of adhesive layer thickness, reduce the stiffness of linear rolling bearings, etc., and achieve the effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

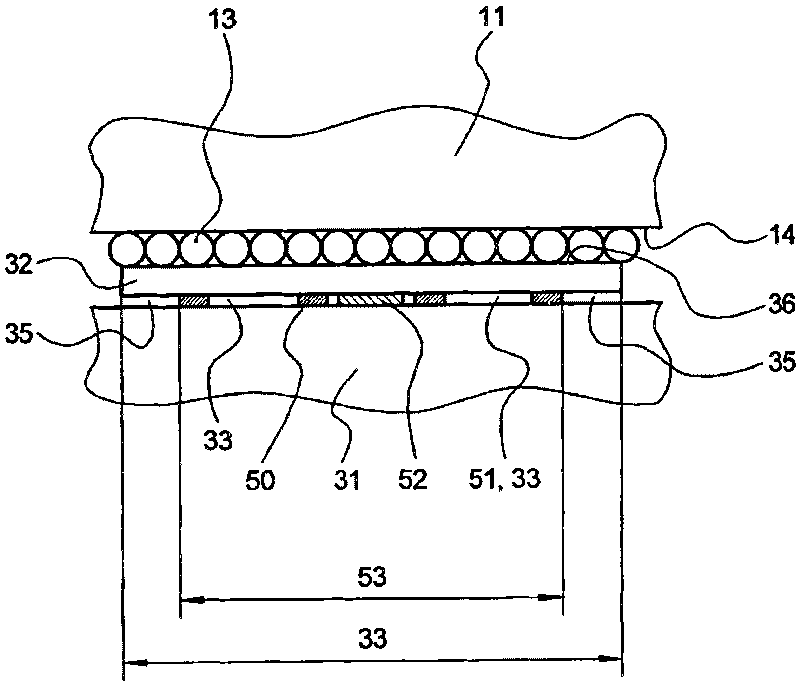

[0021] The linear rolling bearing according to the invention can be produced in that the carriage running surface formed integrally on the main body in the linear rolling bearing known from DE 10 2007 056 862 is replaced by a running surface component with a carriage running surface described below. DE 10 2007 056 862 is therefore cited in full and forms the content of the present application.

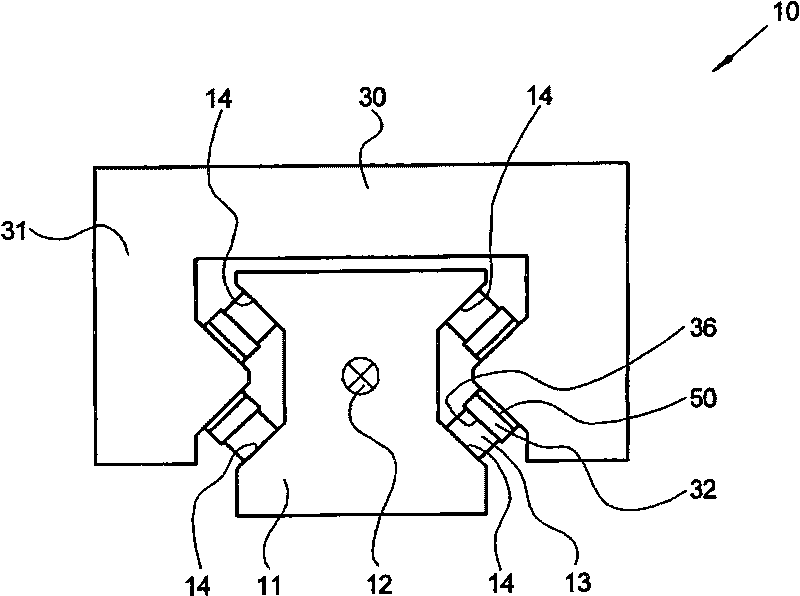

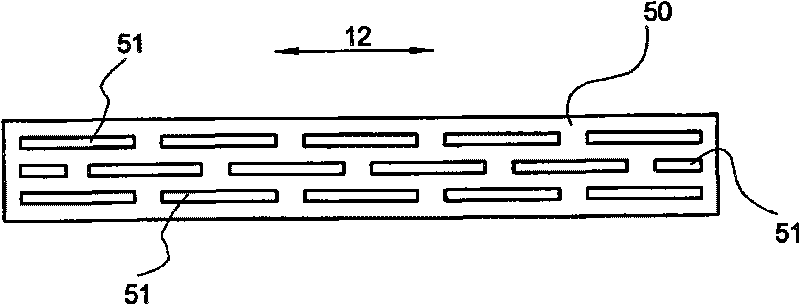

[0022] figure 1 A roughly schematic cross-section through a linear rolling bearing 10 according to the invention is shown. The linear rolling bearing 10 comprises a guide rail 11 made of hardened rolling bearing steel extending in a longitudinal direction 12 , wherein the longitudinal direction 12 is oriented perpendicular to the plane of the drawing. The guide rail 11 has a substantially constant cross-sectional shape over its entire longitudinal extent, a total of four flat rail running surfaces 14 being provided for the substantially cylindrical rolling bodies 13 .

[0023] The gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com