Multi-cylinder oilless compressor of refrigerating agent recovery machine

A technology for recycling machines and refrigerants, applied to machines/engines, multi-stage pumps, mechanical equipment, etc., can solve the problems of not being able to make multi-cylinder structures, limited work efficiency improvement, and refrigerant leakage into the air, etc., and achieve the pumping rate. Increase, improve service life, reduce the effect of current impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

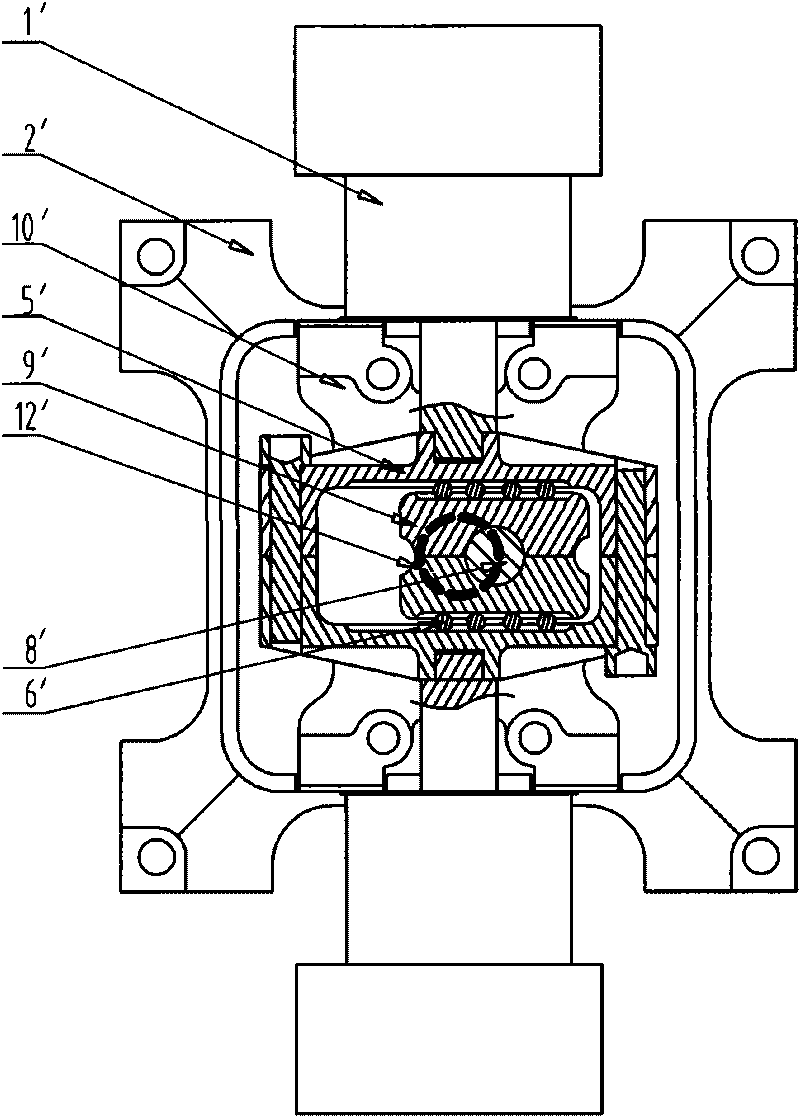

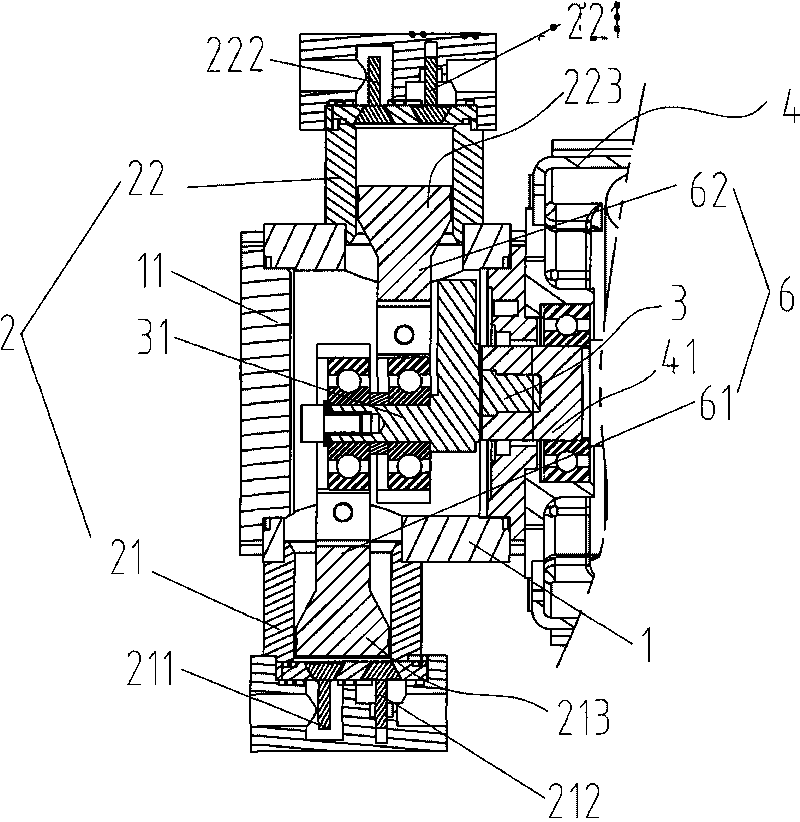

[0020] like image 3 and 4 As shown, it includes a box body 1, a cylinder 2, a crankshaft 3 arranged in the box body, and an output spindle 41 connected to the motor 4 connected to the crankshaft 3. The structure of the whole machine is simple, the parts are relatively few, and failures are not easy to occur, and the service life long.

[0021] The casing 1 and the casing cover 11 form a closed crankcase. The crankshaft 3 is provided with an eccentric shaft portion 31 as a common drive shaft of a plurality of connecting rods, the eccentric shaft portion 31 is located in the crankcase, and a plurality of connecting rods 6 are movably connected on the eccentric shaft portion 31, and each connecting rod is mounted on the eccentric shaft portion. 31 are arranged in sequence in the axial direction. The box body 1 is provided with cylinders 2 equal in number to the connecting rods 6. Here, the number of cylinders can be two, three or four. In this embodiment, two cylinders 21, 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com