Method for preparing MnSO4.H2O by performing flue gas desulphurization on medium-and-low-grade MnO2 ore

一种低品位、烟气的技术,应用在分离方法、化学仪器和方法、硫酸锰等方向,能够解决不利大工业生产装置平稳运行、操作复杂、成本高等问题,达到解决脱硫效率及稳定运行、提高全锰回收率、高效率回收的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

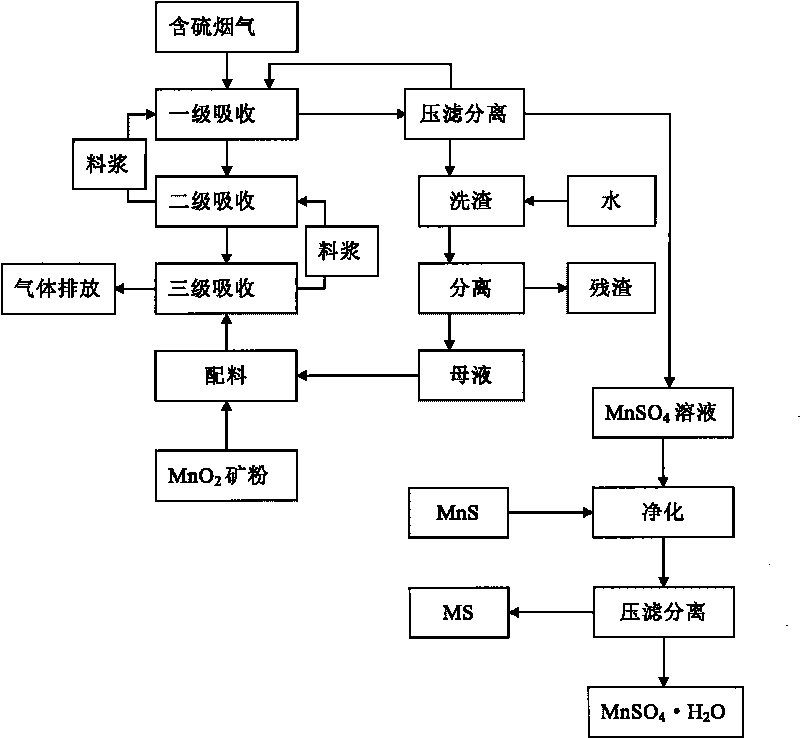

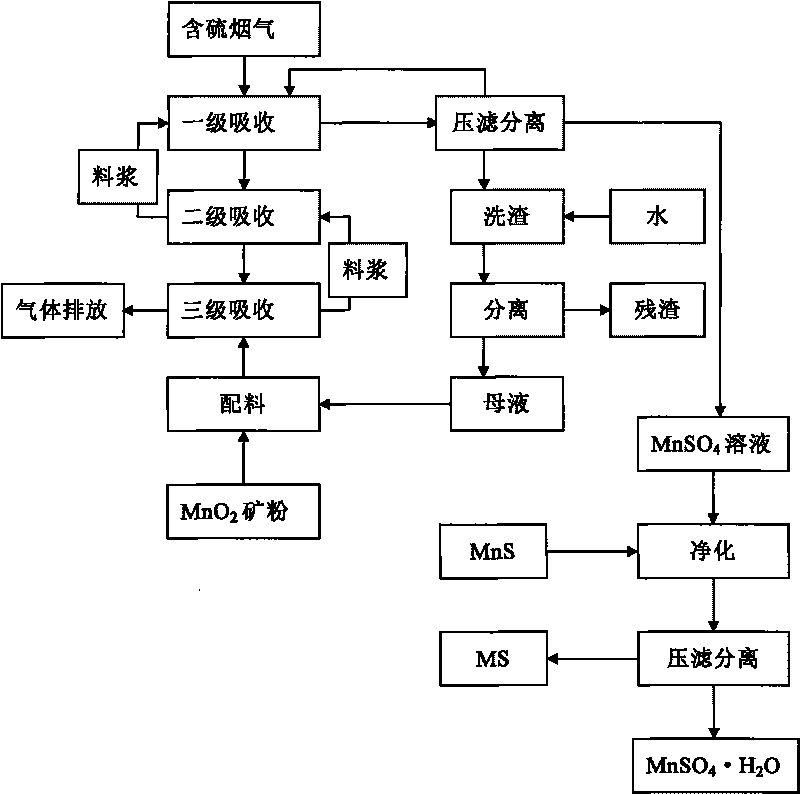

Image

Examples

Embodiment 1

[0025] The sulfur-containing flue gas uses industrial-grade barium carbonate carbon to reduce the exhaust gas of the rotary kiln, with an average gas volume of 25000NM 3 / H, mean SO 2 Content 13400mg / m 3 , The outlet temperature of the cyclone dust collector is about 170°C.

[0026] A select wet base full manganese content 15% MnO 2 Mineral powder is processed by wet ball milling so that its fineness reaches 80 orders, and it is prepared with water to make a slurry with an initial solid-to-liquid ratio of 25% (percentage by weight);

[0027] B first pass the aforementioned sulfur-containing flue gas into the first stage of the absorption device, the superficial gas velocity is controlled at 1.5m / sec, and the liquid-gas circulation spray ratio (gas-liquid ratio) is 15L / m 3 or so, and then add the MnO prepared in step A to the third stage of the absorption device 2 Slurry, and control its reverse flow relative to the sulfur-containing flue gas. The three stages of the three-...

Embodiment 2

[0032] Except the selection of following parameters and steps, embodiment 2 adopts the same steps as embodiment 1 to obtain MnSO 4 ·H 2 O sample 2 # :

[0033] MnO 2 The total manganese content on wet basis is 9.10%, and it is processed by wet ball milling to make the fineness reach 100 mesh. The initial solid-liquid ratio of the slurry is 30%, and the liquid-gas circulation spray ratio is 17L / m 3 Around, the superficial velocity is 1.3m / sec, the third-stage outlet temperature is 70°C, and the third-stage outlet is SO 2 The content is 271-640mg / m 3 .

[0034] After five consecutive return operations, the mother liquor MnSO 4 The concentration is 289g / L, the obtained clear solution is adjusted to PH=4 with dilute sulfuric acid, and the temperature of the solution is controlled at 50°C; the obtained filter cake is stirred and washed with water at 60°C for 1.5 hours, and the ratio of material to water is controlled at 1:5, and the obtained mother liquor For the preparation o...

Embodiment 3

[0037] Except the selection of following parameters and steps, embodiment 3 adopts the same steps as embodiment 1 to obtain MnSO 4 ·H 2 O sample 3 # :

[0038] Sulfur-containing flue gas uses industrial strontium carbonate carbon to reduce rotary kiln exhaust gas, with an average gas volume of 17000NM 3 / H, mean SO 2 Content 11500mg / m 3 , The outlet temperature of the cyclone dust collector is 150°C.

[0039] MnO 2 The total manganese content on a wet basis is 14.22%, and it is processed by a wet rod mill. The initial solid-liquid ratio of the slurry is 28%, and the liquid-gas circulation spray ratio is 25L / m 3 Around, the superficial velocity is 1.7m / sec, the third-stage outlet temperature is 60°C, and the third-stage outlet is SO 2 The content is 114-322mg / m 3 .

[0040] After three return operations, the mother liquor MnSO 4 The concentration is 304g / L, the obtained clear solution is adjusted to PH=3.0, and the temperature of the solution is controlled to be 70°C;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com