Adjustable commutation pole winding end forming device

A winding end and forming device technology, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of paint film damage, poor versatility, cumbersome operation, etc., and achieve convenient operation, simple structure, and versatility wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

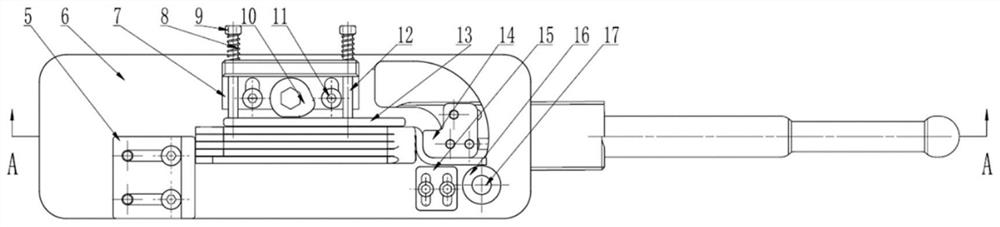

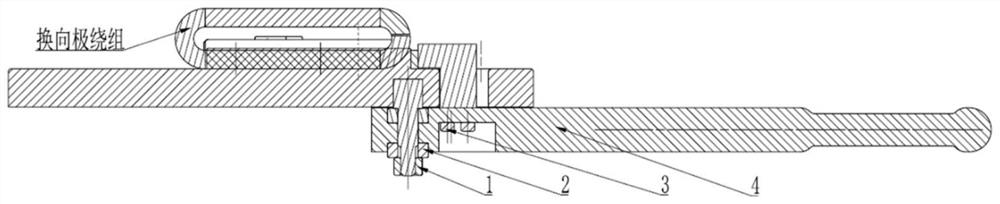

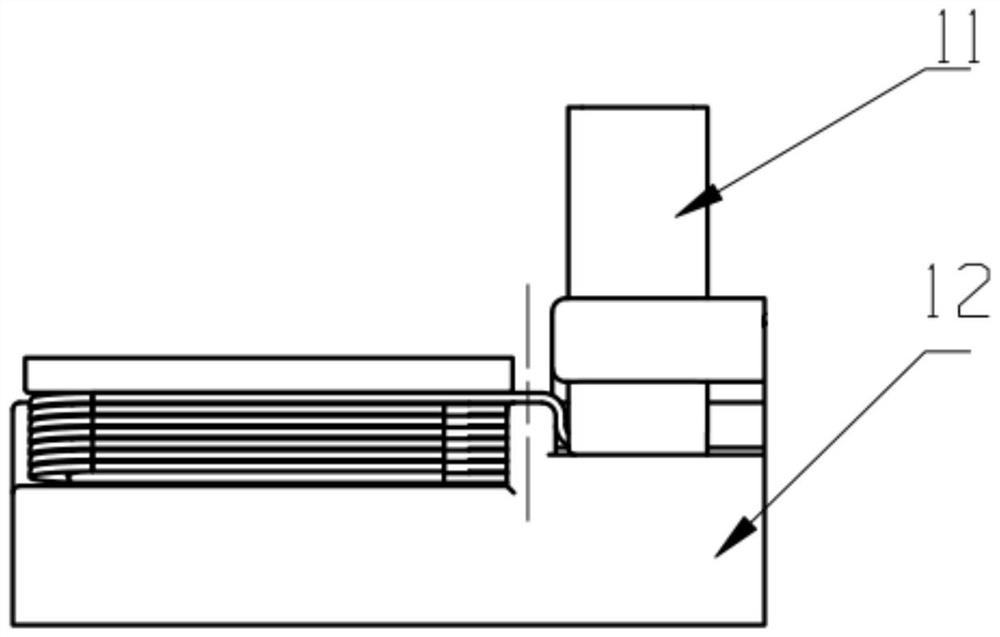

[0029] Such as figure 1 , figure 2 An adjustable reversing pole winding end forming device shown includes a forming base 6; a first positioning block 5 and a second positioning block 15 are respectively installed on the front and rear of the forming base 6, and the bottom of the forming base 6 is equipped with a Rotating handle assembly 4, one side of forming base 6 is equipped with pressing plate support 7.

Embodiment 2

[0031] Based on Embodiment 1, and the first positioning block 5 and the second positioning block 15 are installed symmetrically.

Embodiment 3

[0033] Based on the second embodiment, and the first positioning block 5 can move along the line connecting the first positioning block 5 and the second positioning block 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com