Vibration isolation mass rigid vibration isolation structure for bulkhead of ship

A vibration-resistance and high-quality technology, applied in ships, ship propulsion, ship parts, etc., can solve the problems of few documents and patents, achieve good attenuation, good economy, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings:

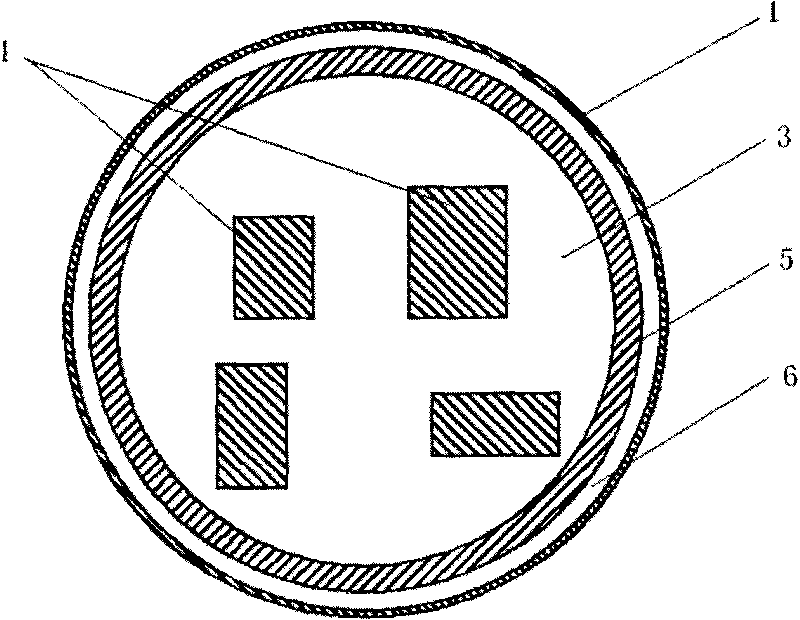

[0023] combine figure 1 and figure 2 , The ship rigid vibration-damping mass composite bulkhead structure of the present invention is composed of a typical bulkhead structure, a vibration-damping mass saw, a vibration-damping mass loop and a structural connection form of impedance mismatch. The anti-vibration mass saw 2 is arranged between each equipment installation area 4 on the bulkhead 3 , and the anti-vibration mass loop 5 is arranged at a rib from the edge of the bulkhead to the pressure-resistant hull 1 . The typical ship bulkhead structure is composed of four parts: bulkhead plate, horizontal plank, stiffener, and installation area on the bulkhead. The rigid anti-vibration mass saw and the anti-vibration mass loop are high shear modulus, high density metal materials. The bulkhead anti-vibration mass saws are arranged so that the multi-stage anti-vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com