Multifunction drawer type soldering iron wiping stand

A drawer-type, multi-functional technology, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problems of serious hidden dangers in solder quality, inconvenient maintenance, and lack of time, so as to facilitate production line operations, installation and use, and convenience cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

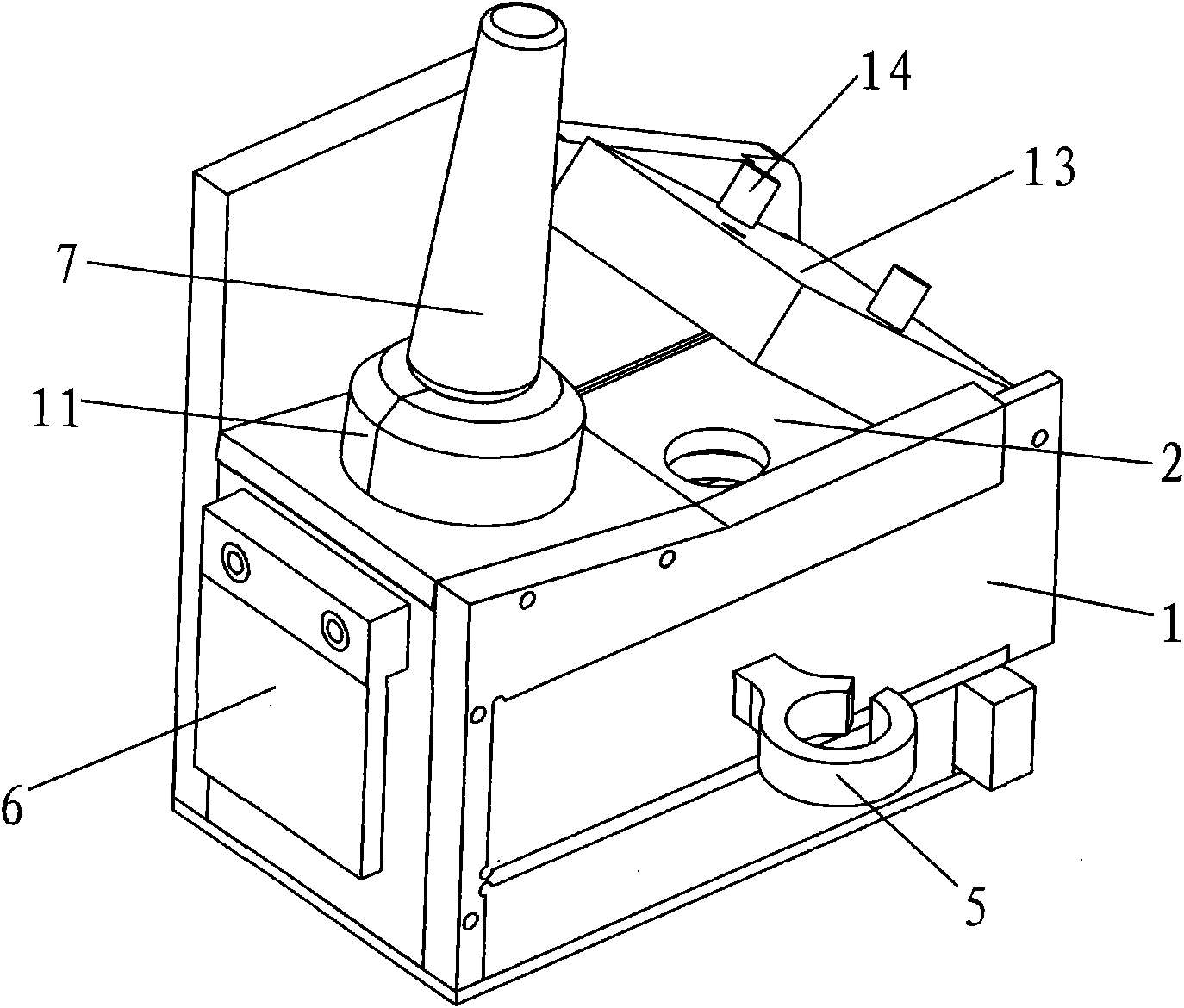

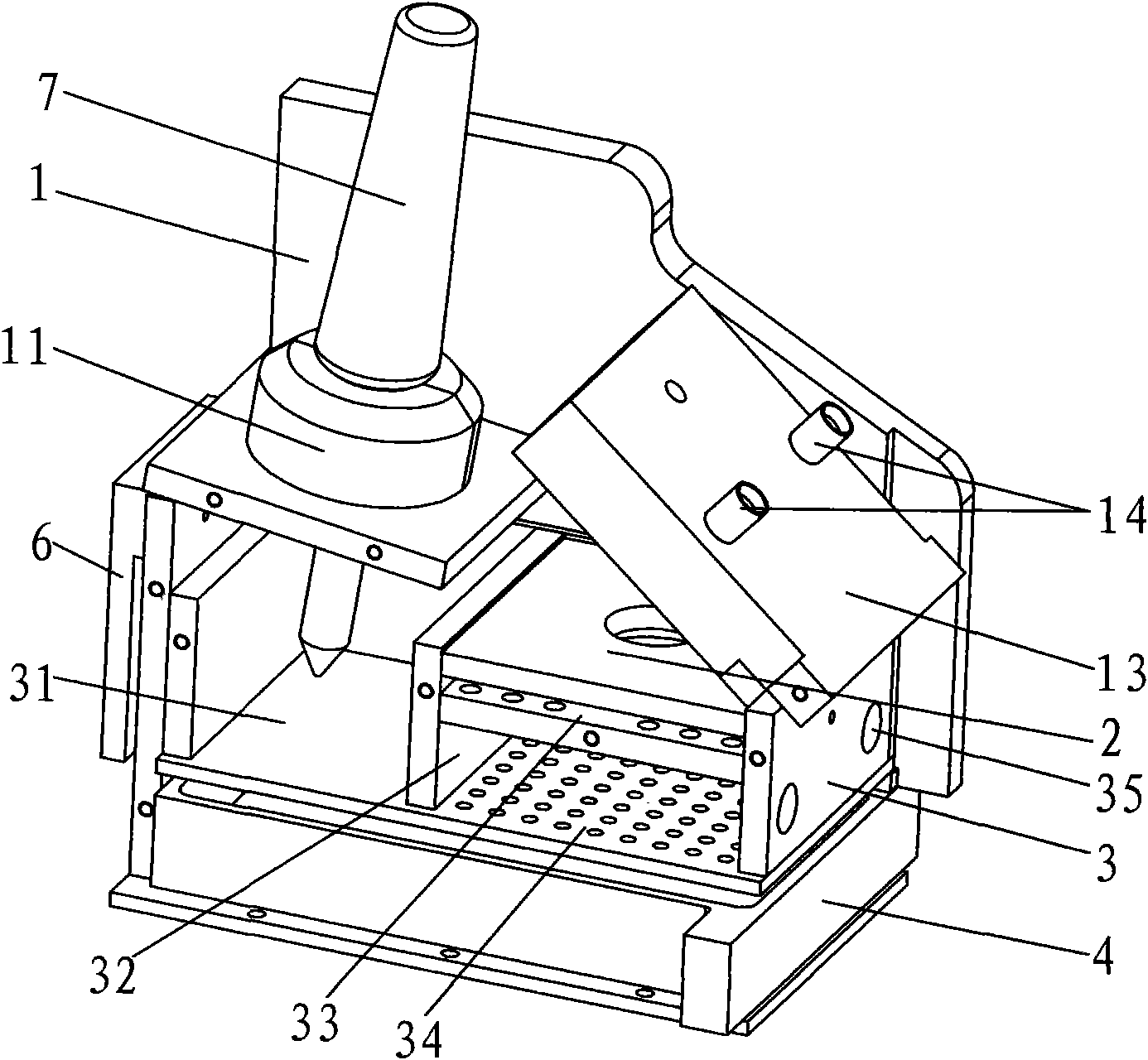

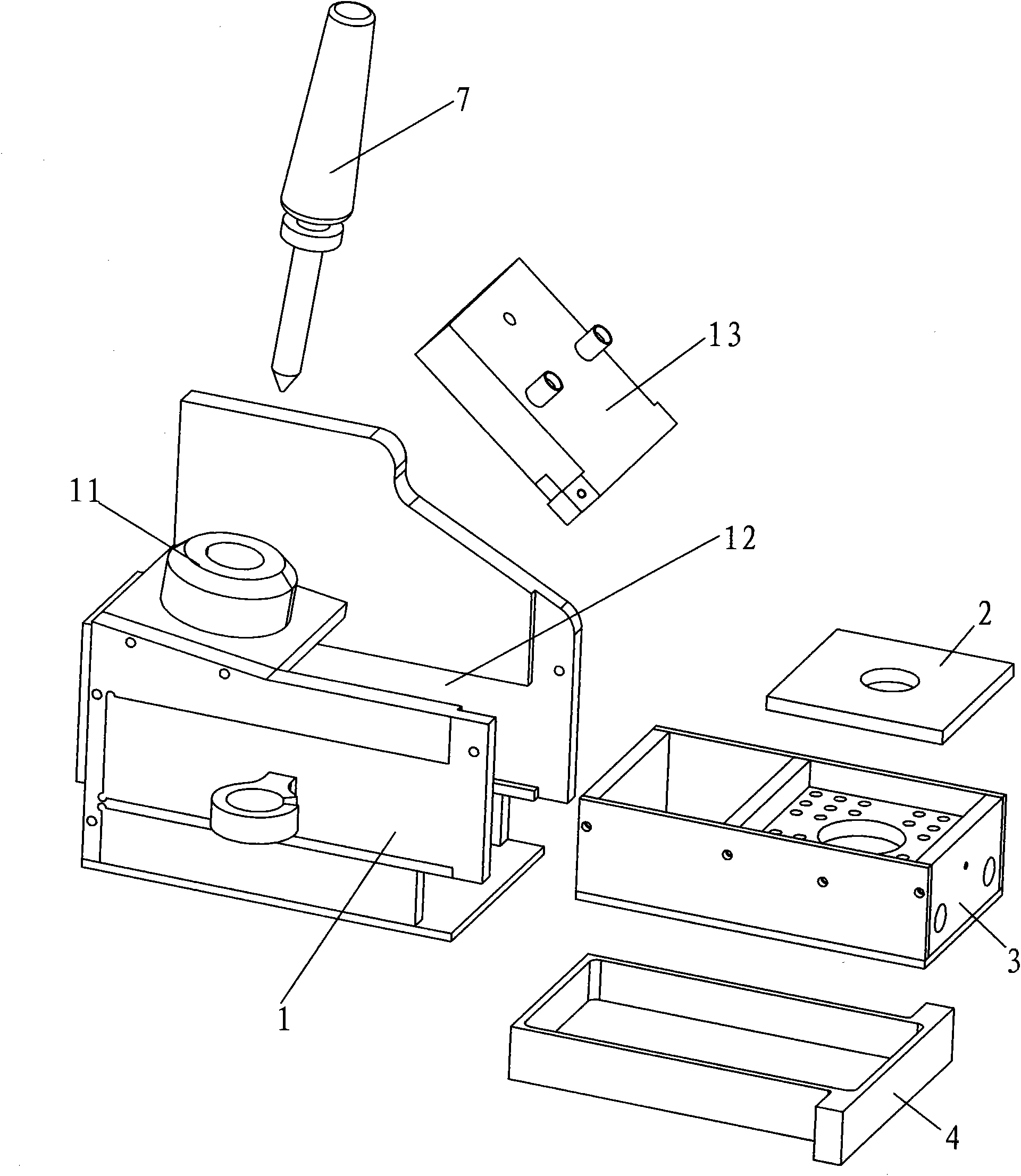

[0026] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~3 As shown, the present invention includes a frame 1, a tin slag box 3, a water container 4 and a water-absorbing foam 2. The upper end surface of the frame 1 is provided with a soldering iron placement port 11 for inserting a soldering iron 7. The frame 1 is from top to bottom. The slag box 3 and the water box 4 can be drawn out along the front end of the frame 1 by sliding down. The slag box 3 and the water box 4 form a drawer structure in the frame 1, and the water-absorbing foam 2 is arranged in the slag box 3 middle.

[0027] Frame 1 is an upper and lower double-layer drawer structure, and the right wall is higher than the soldering iron placement port 11, which is designed for protection to avoid scalding surrounding objects and personnel. The left side of the frame 1 is provided with a power cord hook 5 for clamping the soldering iron power cord. The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com