Rolling mill roll cooling device

A technology of cooling device and pressure roller device, which is applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of the adverse effect of accurate strip finish rolling temperature, difficult cleaning of the strip surface, etc., and achieve simple structure and low production cost. Low, the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, but the present invention is not limited to the following examples;

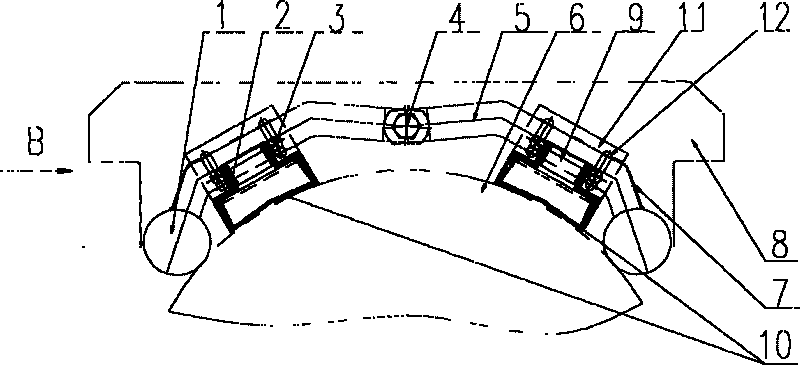

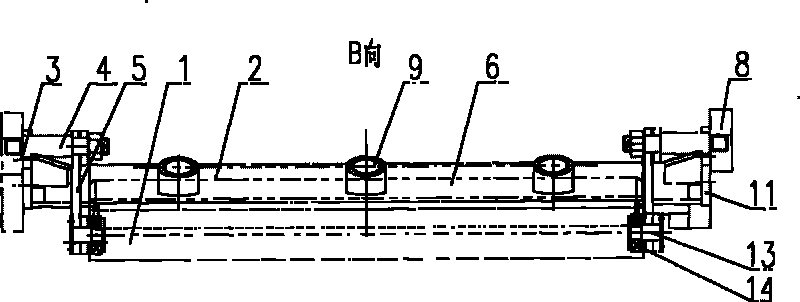

[0024] Such as figure 2 , image 3 , the rolling mill roll cooling device shown includes a cooler 2 for spraying emulsion and a pressing roll device.

[0025] Such as Figure 4 , Figure 5 , Figure 6 As shown, the cooler 2 is arranged in a long box structure along the axial direction of the roll 6, and the two ends of the cooler 2 are provided with connecting plates 11, and the bolts a3 respectively pass through the bolt holes 12 on the connecting plate to firmly connect the cooler 2 to the roll bearing. The upper side of the seat 8; the bolt holes 12 on the connecting plate 11 are arranged as long holes, and the two bolt holes 12 are symmetrical to the central line of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com