Dust separator in vacuum cleaner

A vacuum cleaner and separation device technology, applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems that large particles are easily entrained by the air flow, carried away, and affect the separation effect, so as to achieve improved separation effect, reasonable structure, and improved The effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

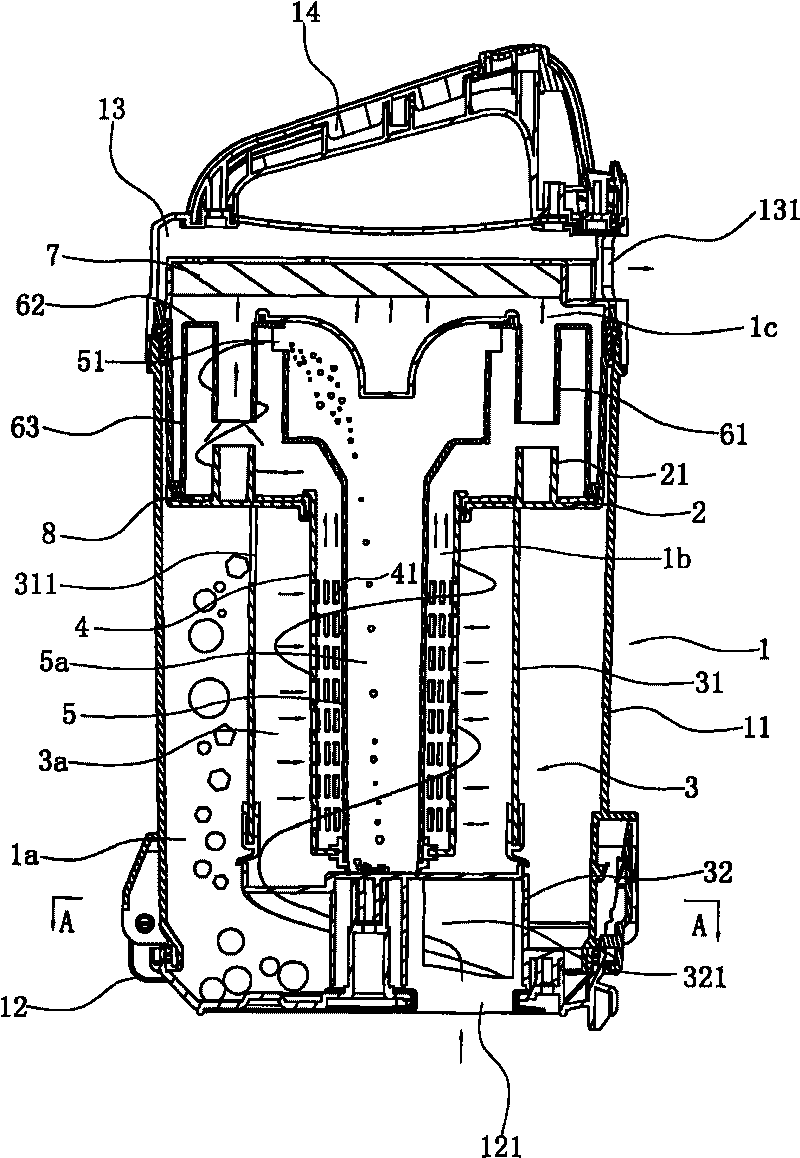

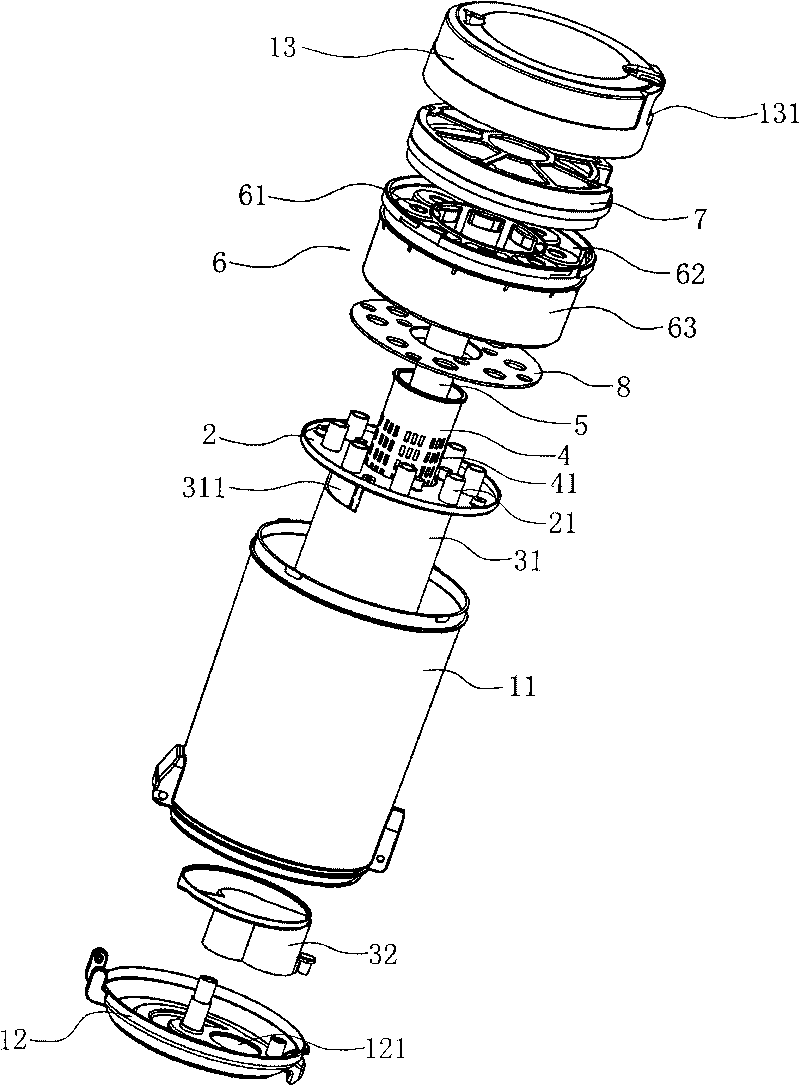

[0020] Such as Figure 1~3 A preferred embodiment of the invention is shown.

[0021] A dust removal and separation device in a vacuum cleaner, comprising a barrel body 1 provided with a total air inlet 121 and a total air outlet 131, a single cyclone separation structure arranged on the lower layer of the barrel body 1 and a parallel cyclone separation structure arranged on the upper layer of the barrel body 1 Structure, these are similar to traditional dust removal and separation devices;

[0022] The key point of the present invention is that the upper layer and the lower layer of the bucket body 1 are separated by a partition 2 .

[0023] The single cyclone separation structure is a dust cup 3 with a total air inlet channel 321 arranged on the lower layer of the barrel body 1. The best design is that the dust cup 3 is composed of a cup b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com