Detecting method and detecting equipment for ultrahigh vacuum accelerating pipe process section

A technology of ultra-high vacuum and detection methods, applied in the direction of material breakdown voltage, etc., to achieve the effects of improving production efficiency, short debugging and training time, and reliable quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

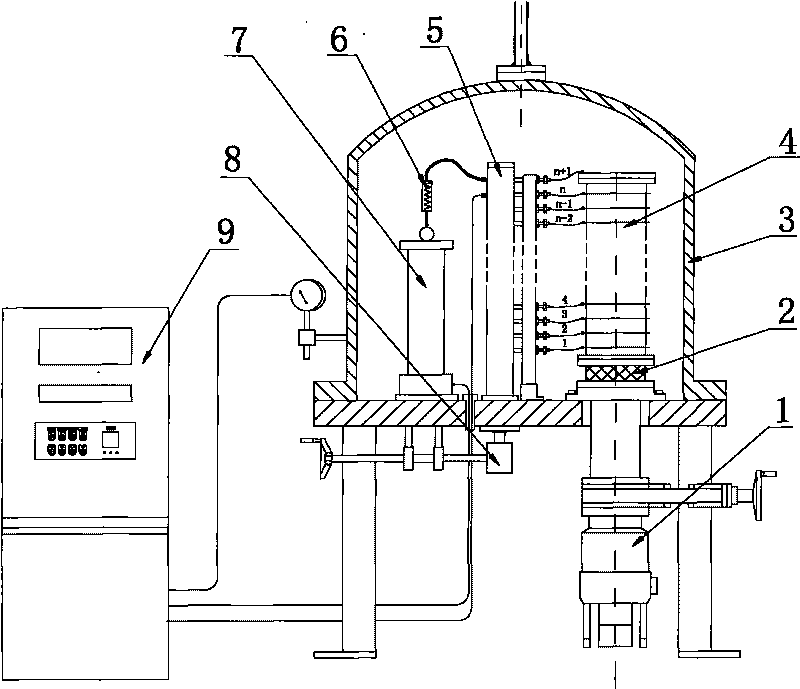

[0018] Such as figure 1 As shown, the detection method used in the process section of the ultra-high vacuum accelerator tube is to carry out voltage training and detection for all the gaps in the process section 4 under test one by one: gradually increase the voltage of the small high-voltage power supply 7 until sparking or leakage occurs in the gap under test Finally, start high-voltage exercise until the voltage rises to 2.5 times the rated working voltage, and reaches the specified leakage and ignition frequency limits, then the gap high-voltage exercise is completed and the quality is up to standard. Only when all the gaps are up to standard, the tested process Section 4 is judged as qualified.

[0019] The detection equipment used for the detection method of the ultra-high vacuum acceleration tube process section is characterized in that it includes a vacuum system 1, a small sealed pressure steel cylinder 3, a high-voltage connection switching operation box 8, a console...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com