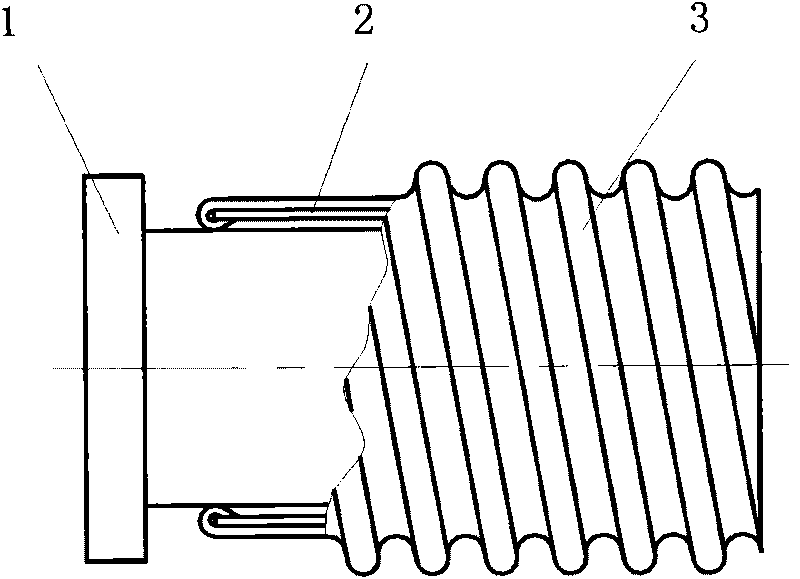

Polytetrafluoroethylene bellows component and preparation method thereof

A teflon, bellows assembly technology, applied in the direction of pipes/pipe joints/pipes, hoses, pipes, etc., can solve the problems of poor bending performance, heavy weight, limited application of non-bending performance, etc. Excellent bending performance and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The PTFE straight blank pipe with an inner diameter of φ8mm is formed according to the PTFE straight blank tube, the end of the PTFE corrugated pipe is restored, cut and installed, and the specific steps are as follows:

[0029] (1) PTFE straight tube forming

[0030] ① Heat the mandrel to 280°C.

[0031] ② Put the PTFE straight tube into the corresponding mandrel.

[0032] ③Start the forward button of the forming equipment, so that the straight polytetrachlorethylene tube and the mandrel rotate together, enter into the mandrel obtained in step 1), and twist together to form a spiral shape.

[0033] ④ When the mandrel with the blank tube rotates in the mandrel to the end of the mandrel, press the stop key.

[0034] ⑤Press and hold the end of the PTFE straight billet tube, press the back button to prevent it from rotating with the mandrel, and press the stop key when the mandrel retreats to the head of the formed spiral pipe.

[0035] ⑥Repeat steps ③, ④, ⑤ until the w...

Embodiment 2

[0047] The PTFE straight blank pipe with an inner diameter of φ9mm is formed according to the PTFE straight blank tube, the end of the PTFE corrugated pipe is restored, sleeved and installed. The specific steps are as follows:

[0048] (1) PTFE straight tube forming

[0049] ① Heat the mandrel to 280°C.

[0050] ② Put the PTFE straight tube into the corresponding mandrel.

[0051] ③Start the forward button of the forming equipment, so that the straight polytetrachlorethylene tube and the mandrel rotate together, enter into the mandrel obtained in step 1), and twist together to form a spiral shape.

[0052] ④ When the mandrel with the blank tube rotates in the mandrel to the end of the mandrel, press the stop key.

[0053] ⑤Press and hold the end of the PTFE straight billet tube, press the back button to prevent it from rotating with the mandrel, and press the stop button when the mandrel retreats to the head of the formed spiral tube.

[0054] ⑥Repeat steps ③, ④, ⑤ until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com