Hydraulic system of hybrid power full-hydraulic excavator based on CPR network

A network mixing, hydraulic system technology, applied in the direction of fluid pressure actuation system components, earth movers/shovels, mechanical equipment, etc., can solve the problems of insignificant energy saving effect and low energy recovery rate, and improve fuel economy. The effect of low pollution, low pollution, and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

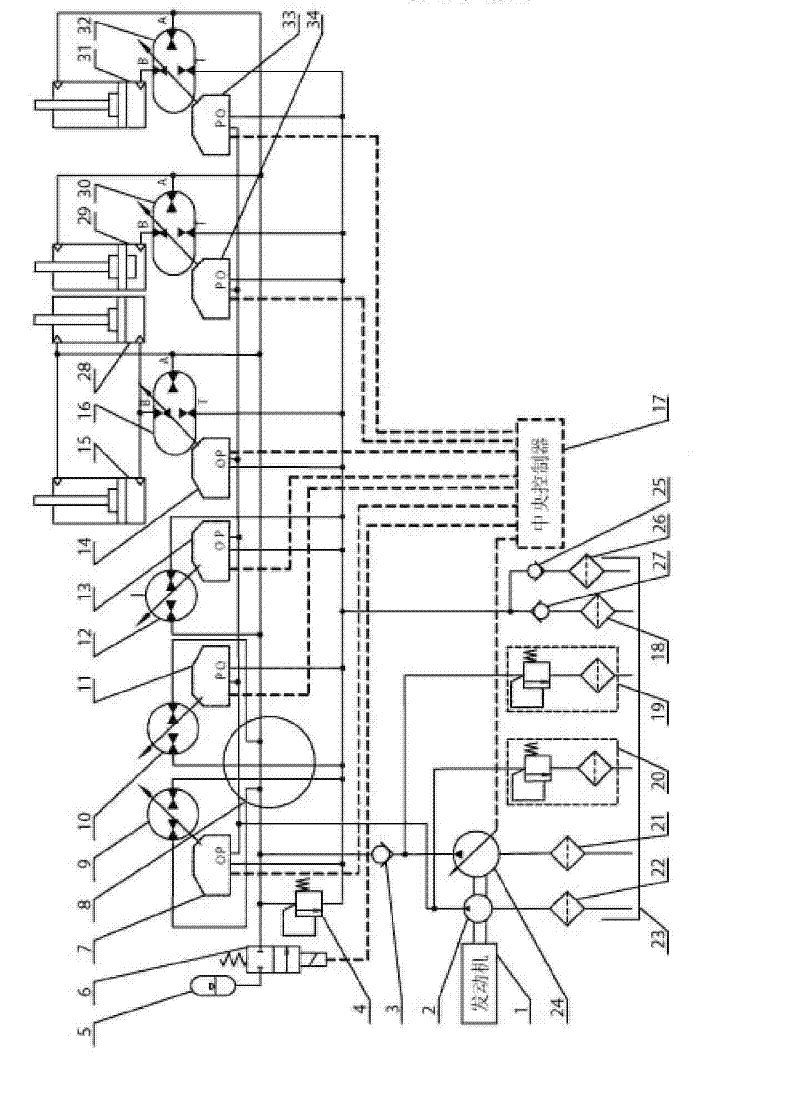

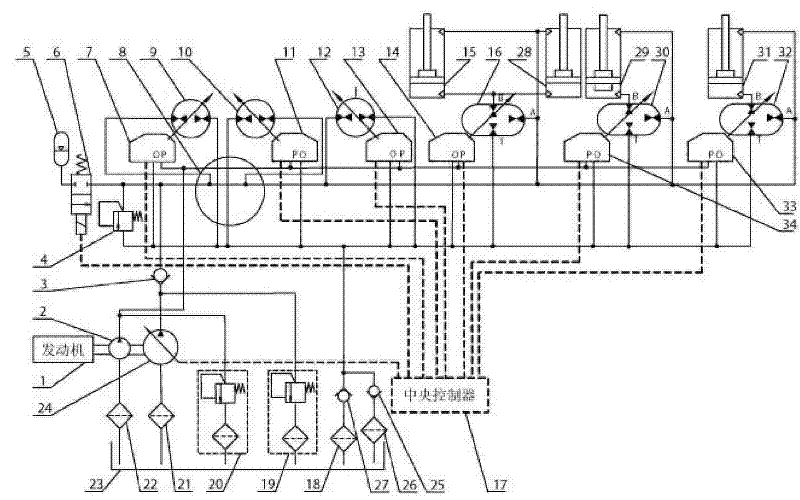

[0014] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment consists of engine 1, quantitative pump 2, safety valve 4, high pressure accumulator 5, electromagnetic reversing valve 6, left travel hydraulic pump / motor control assembly 7, left travel hydraulic pump / motor 9, Right traveling hydraulic pump / motor control unit 11, right traveling hydraulic pump / motor 10, slewing mechanism hydraulic pump / motor control unit 13, slewing mechanism hydraulic pump / motor 12, central controller 17, constant pressure variable pump 24, first working Mechanism cylinder 15, second working mechanism cylinder 28, third working mechanism cylinder 29, fourth working mechanism cylinder 31, first hydraulic transformer 16, second hydraulic transformer 30, third hydraulic transformer 32, first hydraulic transformer control assembly 14 , the second hydraulic transformer control assembly 34 and the third hydraulic transformer control assembly 33;

[0015] The oil i...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that the relief valve assembly 20 is added, the oil outlet of the quantitative pump 2 communicates with the oil inlet port of the relief valve assembly 20, and the outlet of the relief valve assembly 20 The oil port is connected to the oil tank 23. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1Describe this embodiment, the difference between this embodiment and the second embodiment is that a safety valve assembly 19 is added, the oil outlet of the constant pressure variable pump 24 communicates with the oil inlet port of the safety valve assembly 19, and the oil outlet of the safety valve assembly 19 The port connects to the tank 23. Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com