Device for rotating multi-shuttle box

A technology of shuttle box and hollow rotating shaft, which is applied in the direction of textile, textile, papermaking, loom, etc., can solve the problems affecting the inner quality and appearance of the fabric, destroying the structural integrity of the tubular fabric, etc., and achieve easy replacement of the turntable and realization of various and avoid the effect of twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

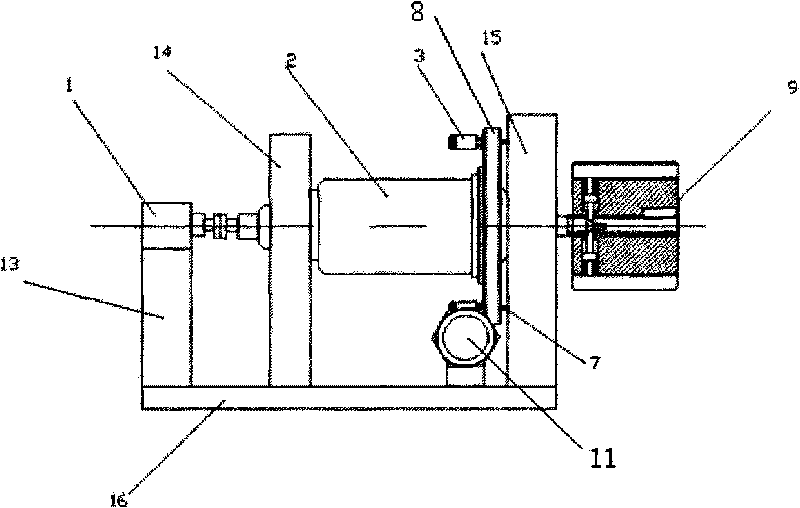

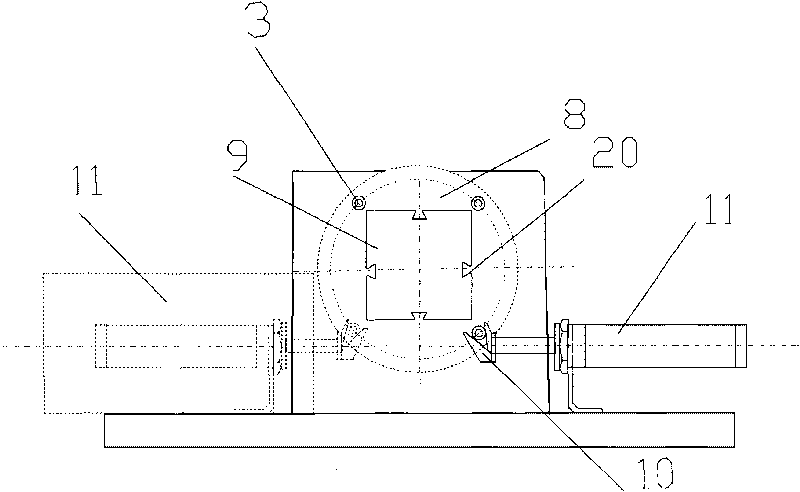

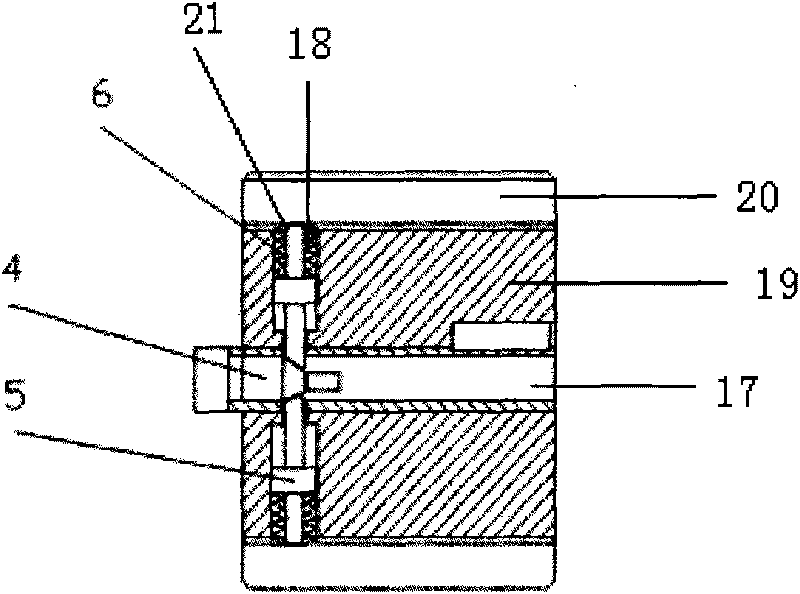

[0022] like figure 1 As shown, it is a structural diagram of the rotary multi-shuttle device, and the rotary multi-shuttle device is composed of a first cylinder 1, a hollow rotating shaft 2, a roller 3, a push rod shaft 4, a lock rod 5, a compression spring 6, and a turntable positioning Component 7, turntable 8, multi-shuttle box 9, push foot 10, second cylinder 11, first bracket 13, second bracket 14, third bracket 15, base 16, axial hole 17, radial hole 18, main body 19 , Shuttle box 20 and shuttle locking hole 21 are formed.

[0023] The base 16 is fixed on the weft insertion side of the loom, and the base 16 is successively provided with a first support 13, a second support 14 and a third support 15 parallel to each other; the first support 13, the second support 14, the third support 15 and the base 16 Use ordinary carbon steel Q235B (GB221-2000) or aluminum alloy ZL102 (GB / T1173-1995)

[0024] Fix the first cylinder 1 with screws on the first bracket 13, the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com