Dedusting agent composition and using method thereof

A technology of composition and dust suppressant, which is applied in the fields of chemical instruments and methods, dust prevention, earth square drilling, etc., and can solve the problems of harming workers' health, limited effect, hidden danger of accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The dust suppressant composition mainly includes the following components in terms of weight percentage: 0.05% dioctyl sodium sulfosuccinate, 0.05% lauryl betaine, 99.789% water and 0.111% calcium chloride, namely Control the calcium chloride containing 0.01 mole number in every dust lifting agent.

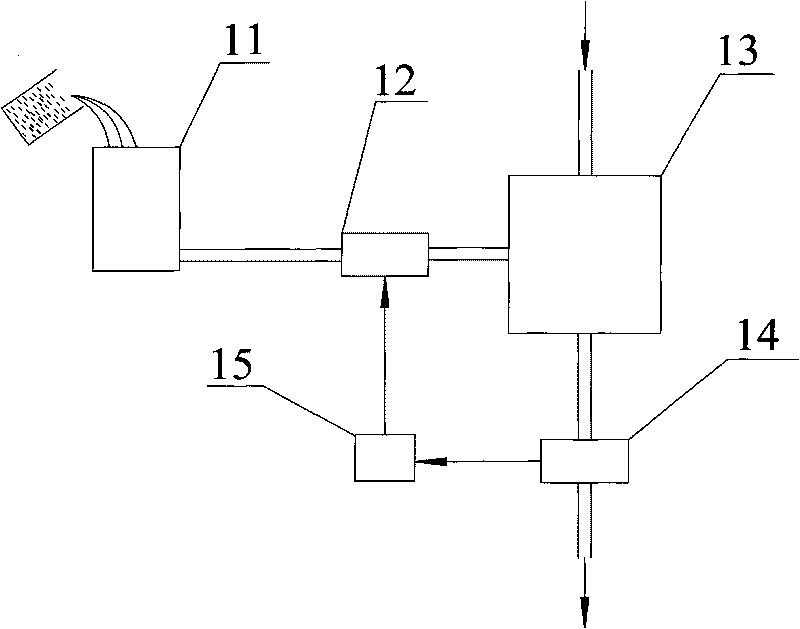

[0048] Such as image 3 As shown, the above-mentioned dust suppressant composition can be applied to coal mines through the following steps, which includes the following steps:

[0049] a. Fully mix 0.05% dioctyl sodium sulfosuccinate, 0.05% dodecyl betaine, 99.789% water and 0.111% calcium chloride according to the weight percentage, and control the mixture per liter Containing 0.01 moles of calcium chloride, the dust suppressant composition is prepared, and the dust suppressant composition is put into the water tank 11;

[0050] b. When the working face in the coal mine is working, start the clean water pump 14, and simultaneously start the quantitative pump 12 through ...

Embodiment 2

[0059] The dust suppressant composition is composed of the following components in terms of weight percentage: 0.05% dioctyl sodium sulfosuccinate, 0.05% lauryl betaine, 99.789% water and 0.111% calcium chloride, namely Control the calcium chloride containing 0.01 mole number in every dust lifting agent.

[0060] Such as image 3 As shown, the above-mentioned dust suppressant composition can be applied to coal mines through the following steps, which includes the following steps:

[0061] a. Fully mix 0.05% dioctyl sodium sulfosuccinate, 0.05% dodecyl betaine, 99.789% water and 0.111% calcium chloride according to the weight percentage, and control the mixture per liter Containing 0.01 moles of calcium chloride, the dust suppressant composition is prepared, and the dust suppressant composition is put into the water tank 11;

[0062] b. When the working face in the coal mine is working, start the clean water pump 14, and simultaneously start the quantitative pump 12 through t...

Embodiment 3

[0067] The difference between embodiment 3 and embodiment 2 is that the weight percentage of each component is different, and the dust suppressant composition is made up of the following components according to weight percentage: 0.06% dioxoctyl sodium sulfosuccinate, 0.06% Dodecyl betaine, 99.547% of water and 0.333% of calcium chloride, and controlled to contain 0.03 moles of calcium chloride per dust elevating agent.

[0068] Such as image 3 Shown, above-mentioned dedusting agent composition can be applied in the spray dedusting system of coal mine by following steps, it comprises the following steps:

[0069] d. Fully mix 0.06% dioctyl sodium sulfosuccinate, 0.06% lauryl betaine, 99.547% water and 0.333% calcium chloride according to the weight percentage, and control the mixture per liter Containing 0.03 moles of calcium chloride in the water, the dust suppressant composition is prepared, and the dust suppressant composition is put into the water tank 11;

[0070] e. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com