Finishing coat of aqueous non-viscous paint

A technology of non-stick coatings and topcoats, applied in the direction of coatings, etc., can solve the problems that affect the appearance and application performance of coatings during coating construction, coarse particles attached to the surface of workpieces, spraying guns, etc., to achieve good storage stability of coatings and Spray application performance, improved chemical resistance and durability, high sprayable thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

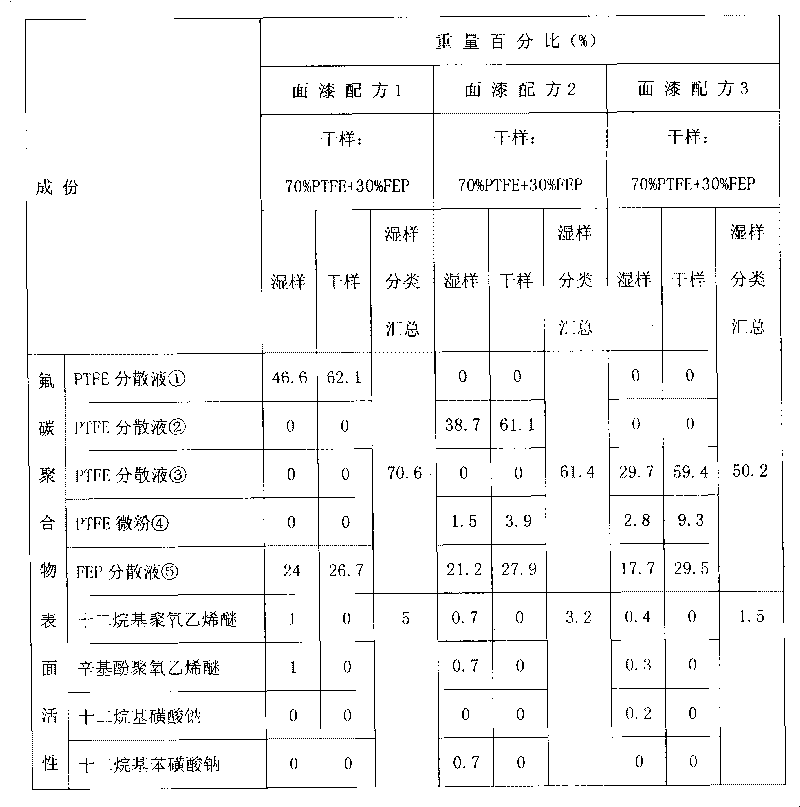

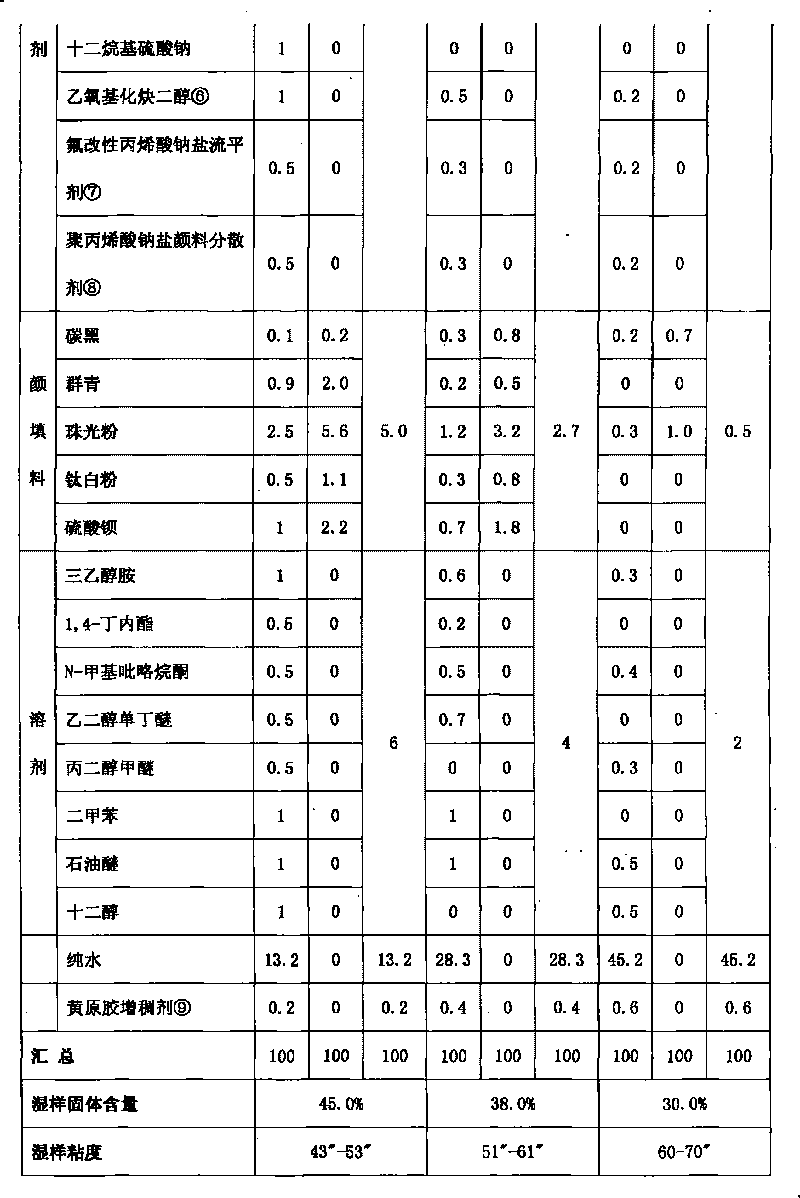

[0218] Table 1 - Topcoat Formulations for Waterborne Nonstick Coatings

[0219]

[0220]

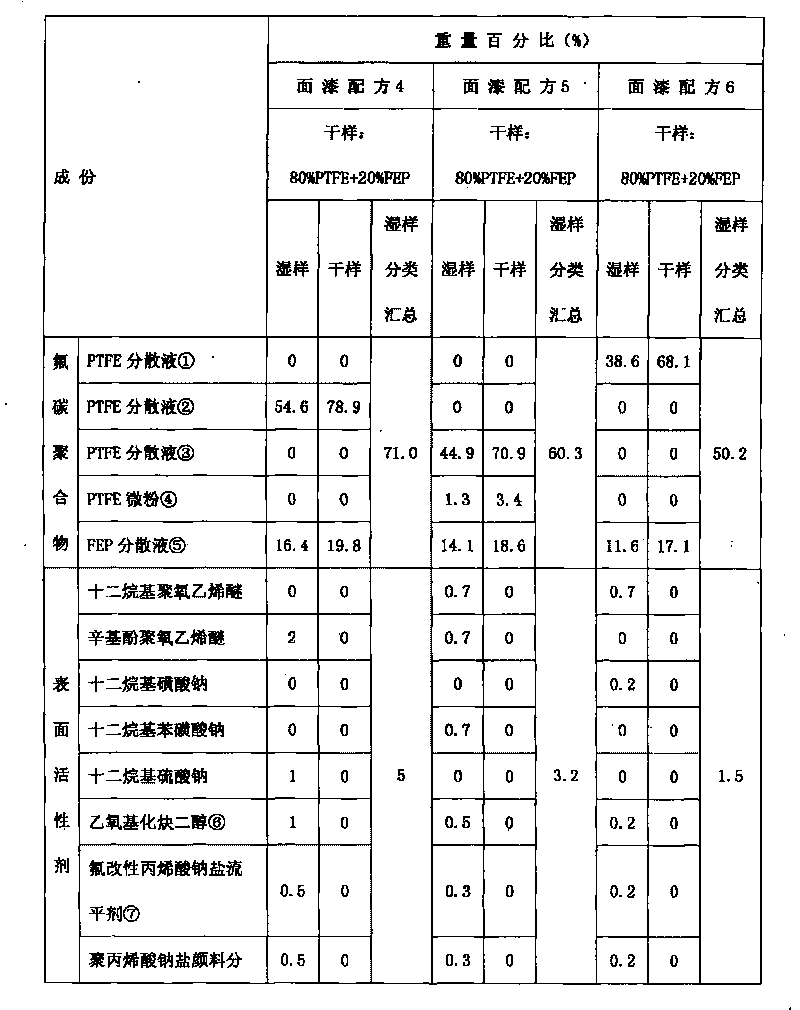

[0221] Table 2 - Topcoat Formulations for Waterborne Nonstick Coatings

[0222]

[0223]

[0224] Table 3 - Topcoat Formulations for Waterborne Nonstick Coatings

[0225]

[0226]

[0227]

[0228] Table 1, 2, 3 Introduction of special raw materials:

[0229] ① The polytetrafluoroethylene dispersion produced by Shandong Dongyue Polymer Material Co., Ltd. has a solid content of 60%, the brand name is DF-302, and the PFOA content is normal.

[0230] ② The polytetrafluoroethylene dispersion produced by Shandong Dongyue Polymer Material Co., Ltd. has a solid content of 60%, and the brand name is DF-302- (de-PFOA process, PFOA content is less than 50ppm).

[0231] ③ The polytetrafluoroethylene dispersion produced by Zhongwu Chenguang Chemical Research Institute has a solid content of 60%, the brand name is SFN-1, and the PFOA content is normal.

[0232] ④ The polytetra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com