Internally circulating wet flue gas desulfurization tower

A technology of wet flue gas desulfurization and internal circulation, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve problems such as large desulfurization water consumption, secondary pollution of wastewater, and easy corrosion of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

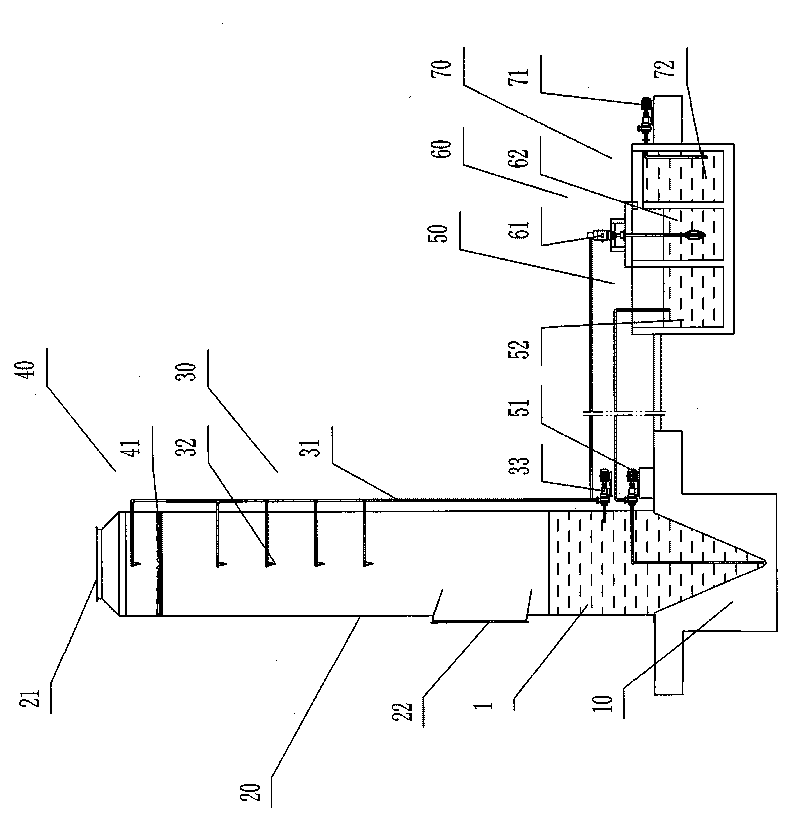

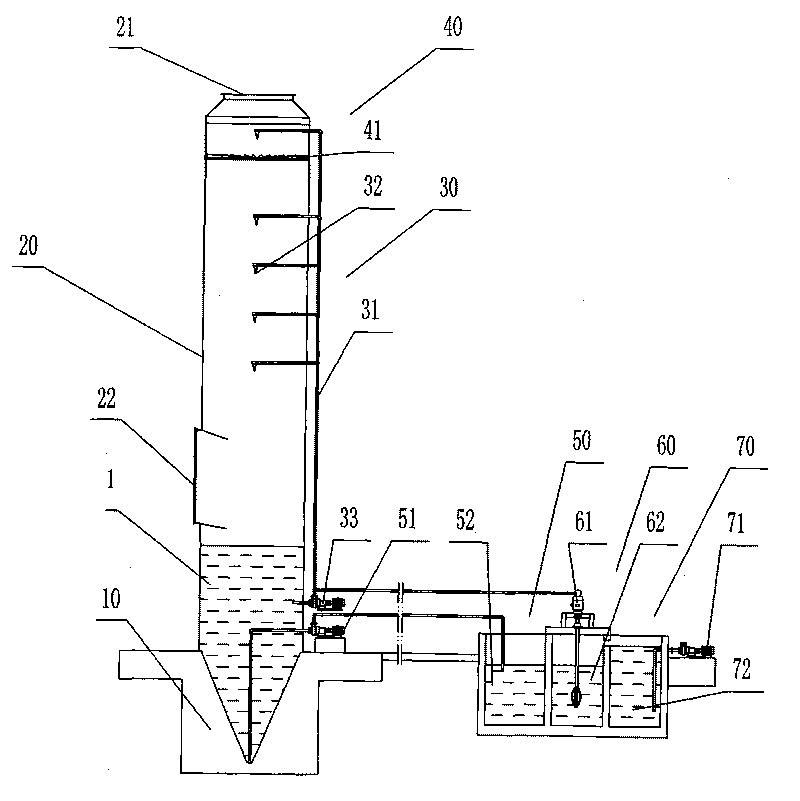

[0014] An internal circulation wet flue gas desulfurization tower, comprising a tower base 10 and a tower body 20, a desulfurization system 30 is provided inside the tower body 20, a flue gas outlet 21 is located at the upper end of the tower body 20, and a desulfurization system is installed at the flue gas outlet 21 The mist system 40 has a flue gas inlet 22 at the lower end of the tower body 20 , and the air inlet 22 and the tower body 20 are in a downward tangential direction. At the bottom of the tower body 20 is a slurry tank 1, the upper part of the slurry tank 1 is connected with the liquid replenishment system 70, the bottom of the slurry tank 1 is connected with the ash cleaning system 50, and a pulping system 60 is also provided outside the tower body 20 for pulping The system 60 is connected with the desulfurization system 30 through the spray circulation pump 33 .

[0015] The desulfurization system 30 is that a desulfurization pipeline 31 is arranged on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com