Method for preparing ultrafine tea powder

An ultra-fine, tea powder technology, applied in the direction of tea, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of low bioavailability, affecting the nutrition and health functions of tea, and difficult to directly eat or digest tea.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

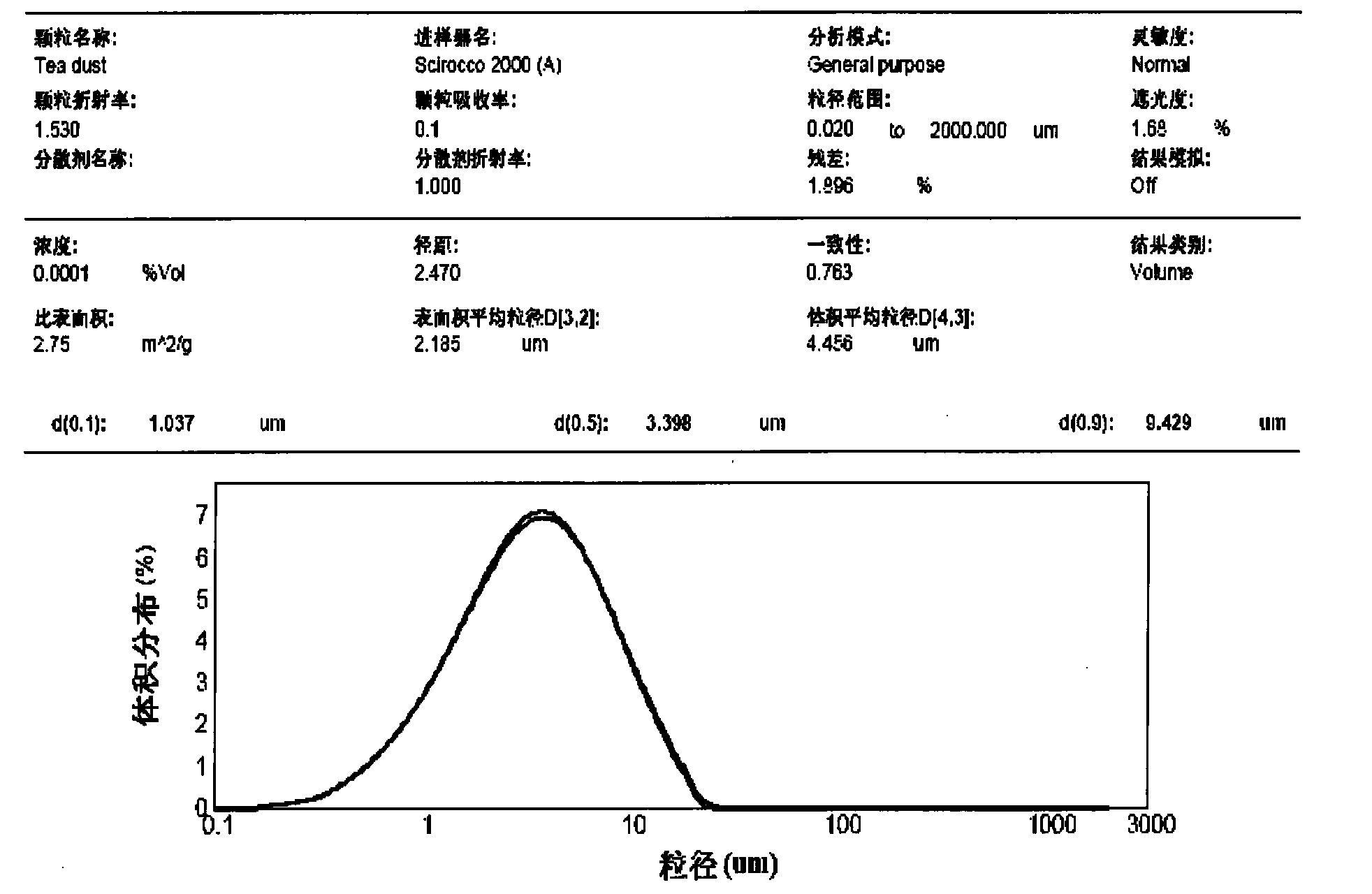

Embodiment 1

[0022] The picked fresh leaves of Yuhua tea were spread out for 4-6 hours, and the water content was controlled at 75-78%, and the water content was further reduced to 65-68% by 6CZS-150 steam hot greening machine (Zhejiang Shangyang Machinery Co., Ltd.). %, using microwave grading drying technology to dry, the processing parameters are 500-1000 grams of leaves, and the transmission speed is 450-750rmin -1 , microwave power 4.25-7.65kW; dry the above tea powder, further reduce the water content to 6-10%, and then use a 30B type universal pulverizer (Changzhou Qiangli Drying Equipment Co., Ltd.) to initially pulverize the dry tea to about 20 mesh 6CFX-30 type vertical winnowing machine (Zhejiang Wuyi Huashuai Tea Machinery Co., Ltd.) is used to sieve dust and impurities according to their weight; then use XK-160 type pulverizer (Changzhou No. Co., Ltd.) crush the tea powder 10-15 times with a maximum distance of 1-3mm to fully destroy the plant cell wall; use the QLM-100KA jet ...

Embodiment 2

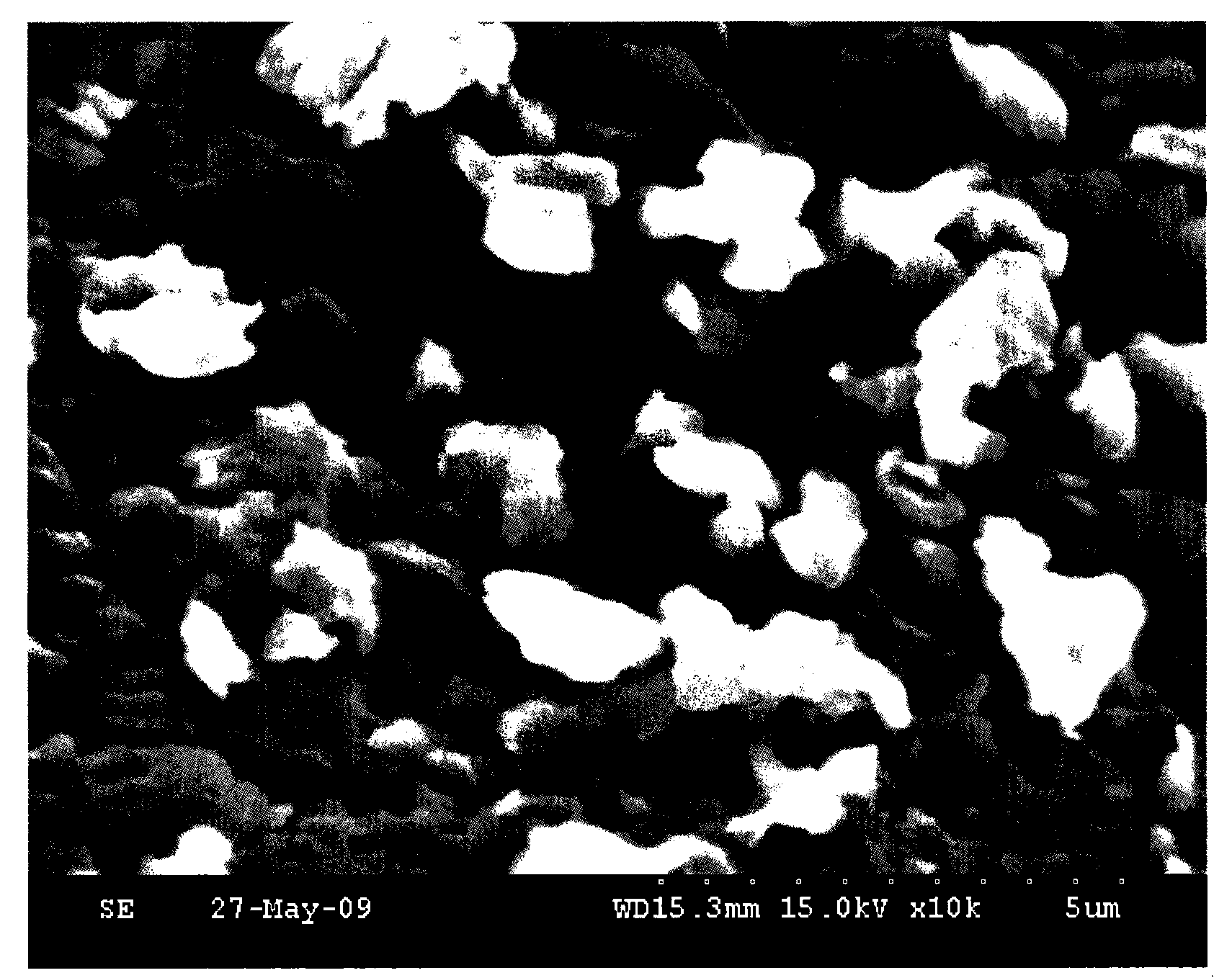

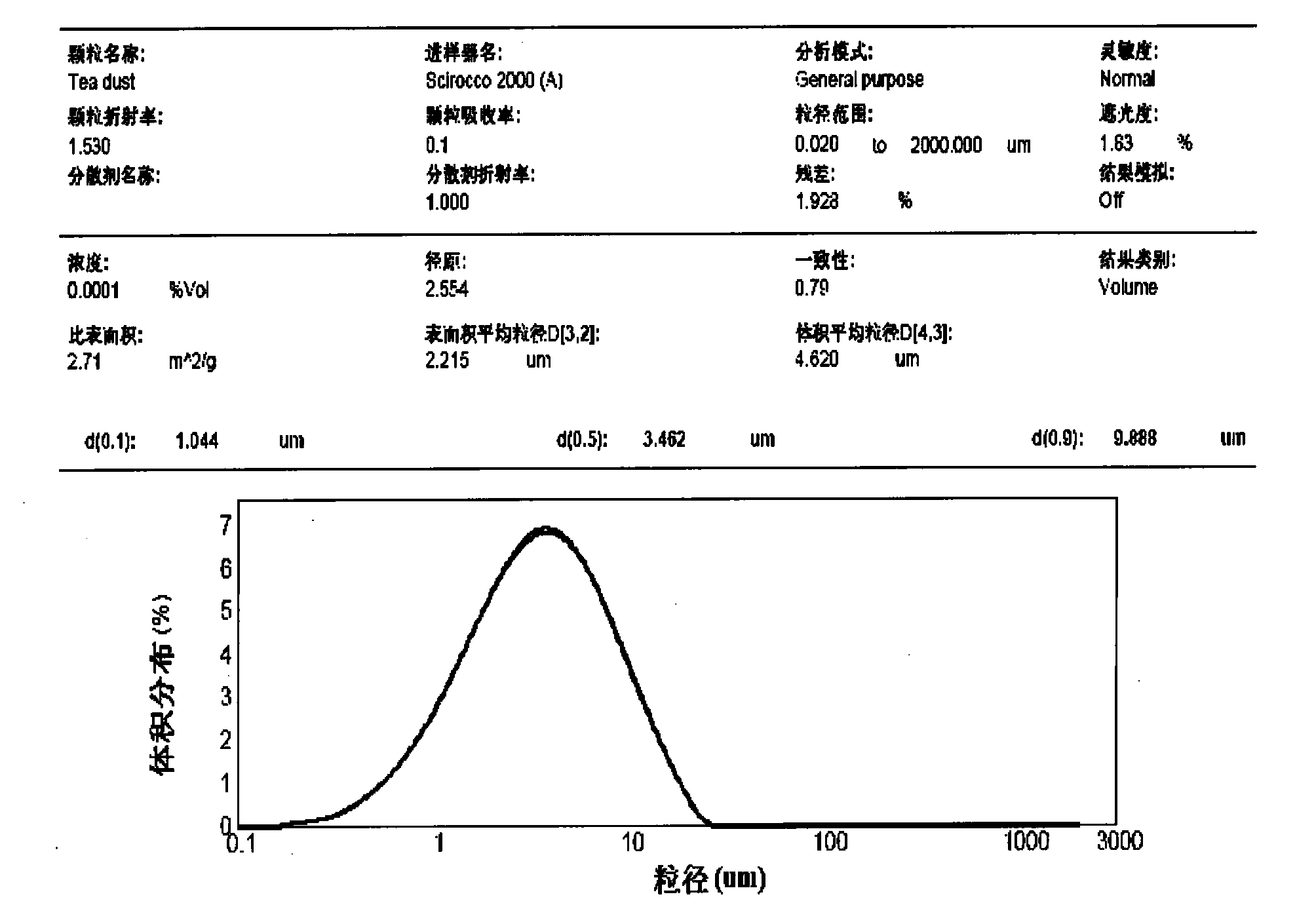

[0024] Spread the newly picked selenium-enriched green tea for 4-6 hours, with the water content controlled at 75%, and after the 6CZS-150 steam thermal green tea is finished, the water content is further reduced to 65-68%. The parameters are 500-1000 grams of leaf throwing and 450-750r min of conveying speed -1 , with a microwave power of 4.25-7.65kW; dry the above tea powder, then use a 30B type universal grinder to crush the dry tea leaves to about 100 mesh, use a fan to remove dust and impurities; then use an XK-160 type grinder to crush the tea Powder 10-15 times, the maximum distance is 1-3mm, fully destroy the plant cell wall; the tea powder obtained by the primary ultrafine pulverization is pulverized for the second time with a jet mill, and the processing times are 5-10 times. The average particle size of the product detected by the laser particle size analyzer is 3.462 μm ( image 3 ); observed by scanning electron microscope, the tea grains are uniform and well dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com