Spherical plain bearing

A sliding bearing, spherical technology, applied in the direction of bearing, bearing assembly, bearing components, etc., can solve the problem of vibration damping and other problems, achieve effective vibration damping, increase driving comfort, and isolate noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

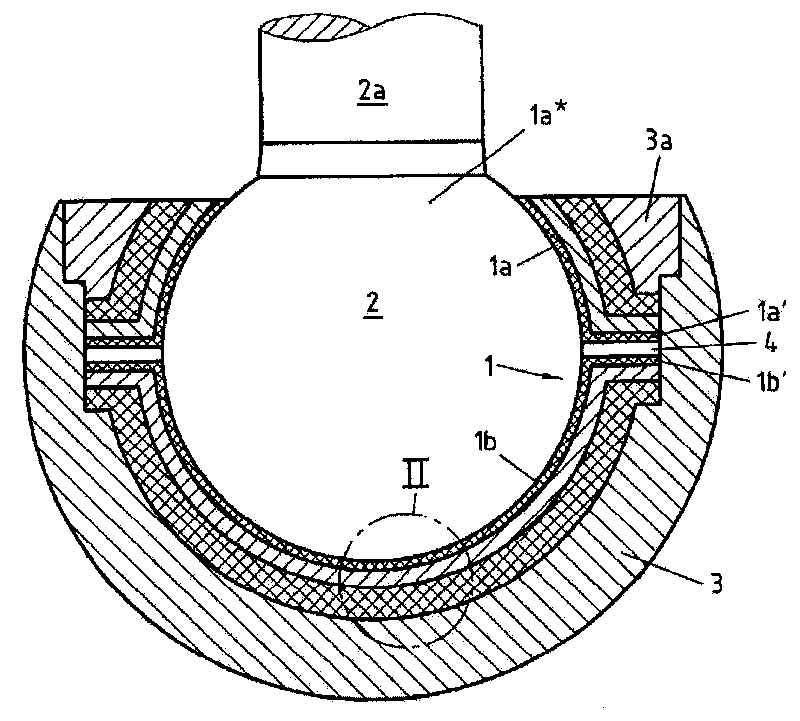

[0022] as in figure 1 The ball and socket joint according to the invention shown in , comprises a self-lubricating spherical plain bearing 1 and a ball joint 2 which is mounted without play in the spherical plain bearing 1 and on which a bearing pin 2a is integrally formed. The spherical plain bearing 1 is mounted in a bearing housing 3 and is held in this position by a ring element 3 a which is an integral part of the bearing housing 3 .

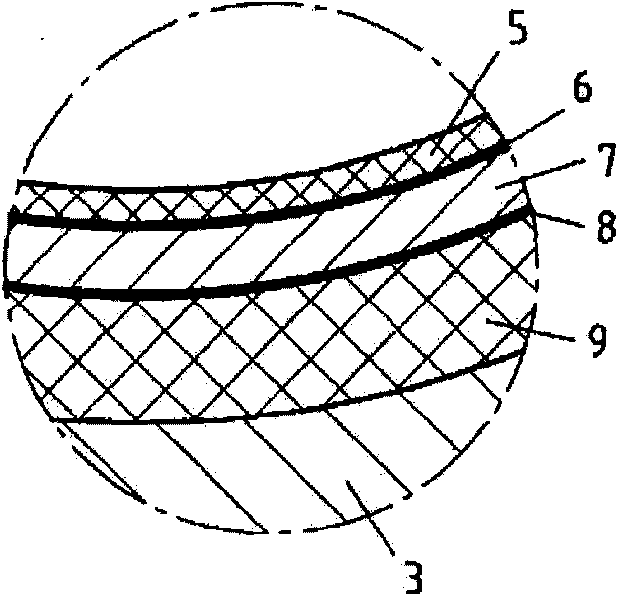

[0023]The spherical plain bearing 1 comprises two spherical plain bearing housings 1a, 1b, the upper plain bearing housing 1a comprising a central opening 1a* through which a bearing pin 2a integrally formed on a ball joint 2 projects out of the socket outside the festival. The opening 1 a * is dimensioned in such a way as to allow the desired movement of the bearing pin 2 a relative to the spherical plain bearing 1 . The two plain bearing shells 1a, 1b each have an annular, radially outwardly directed collar 1a', 1b' on their mutually op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com