Method for producing brush steam seal ring

A brush-type steam seal and production method technology, applied in the direction of engine sealing, leakage prevention, engine components, etc., can solve the problems of poor sealing performance, large leakage, easy vibration, etc., and achieve good sealing effect and high mechanical strength. , the effect of good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Accompanying drawing non-restrictive discloses several specific embodiments of the present invention, in conjunction with accompanying drawing, production method of the present invention is further described as follows:

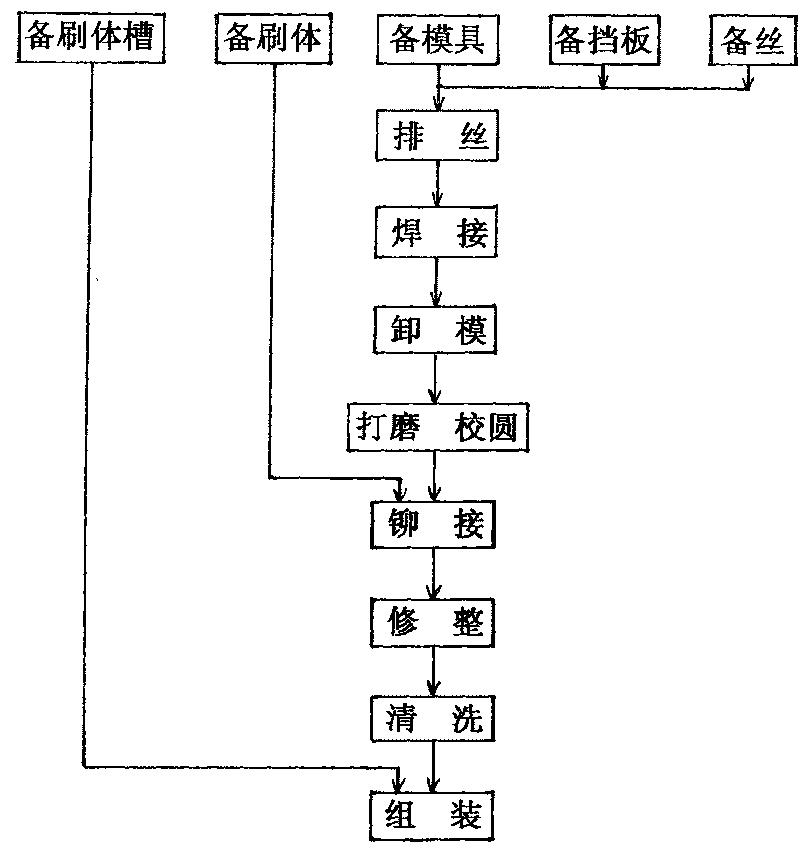

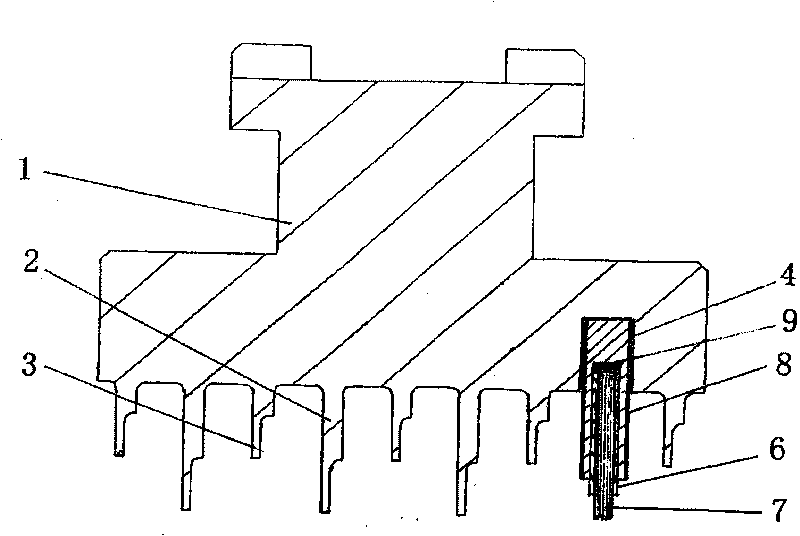

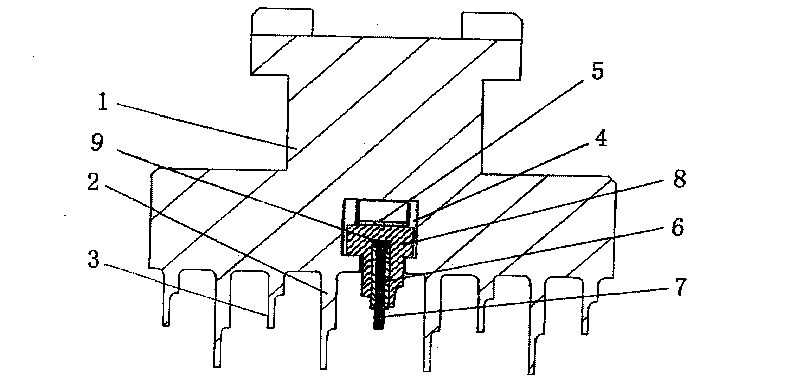

[0029] The brush-type steam seal ring produced by the method of the present invention is formed by connecting end to end of several sections of steam seal rings, and each section of steam seal ring is mainly composed of ring body 1, high-tooth sealing strip 2, low-tooth sealing strip 3, baffle plate 6, Composed of alloy wire layer 7 and brush body 8, its cross-sectional structure is as attached figure 1 or attached figure 2 As shown, the better method of its large-scale production mainly includes the following steps, see attached figure 1 :

[0030] 1) Spare brush body groove: the arc-shaped brush body groove 4 for installing the alloy wire brush is preset at the appropriate position of each section of the ring body 1 of the steam seal ring; the bru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com