Three-dimensional integral weaving method for grid type prefabricated part and product thereof

A technology of integral weaving and prefabrication, which is applied in the direction of woven fabrics, textiles and papermaking, can solve the problems of weak structural strength and rigidity of grid ribs, poor shear resistance, etc., to improve integrity and comprehensive performance, reduce weight, The effect of avoiding fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

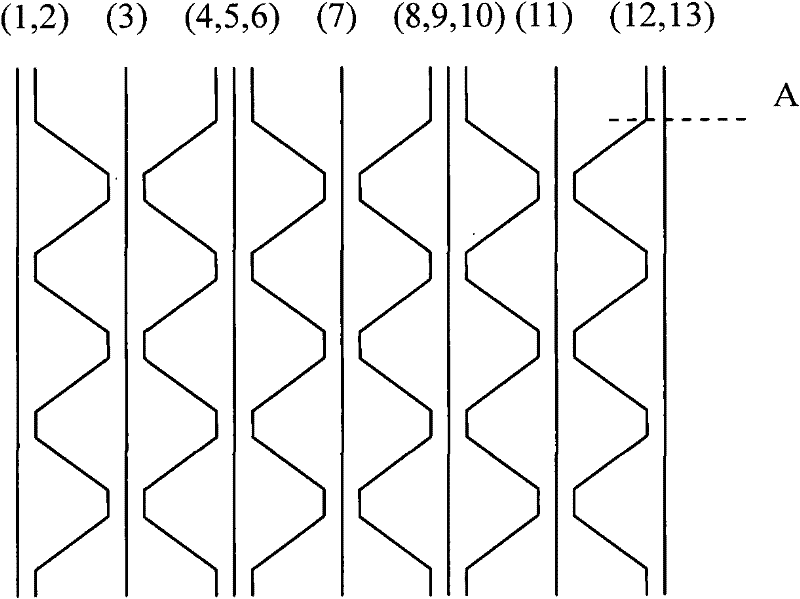

[0032] The weaving method of the prefabricated part whose grid shape is an equilateral triangle (see figure 1 ).

[0033] The cross-section of the triangular grid preform is rectangular, the size is 100*15mm, the weaving structure adopts a three-dimensional five-way structure, the weaving yarn is 1200tex glass fiber, the weaving angle is 30°, and the number of yarns required for design weaving is 780. Among them, there are 520 weaving yarns and 260 axial yarns; according to the shape required by the grid, 60 yarns are designed for each layer, of which 40 are weaving yarns and 20 axial yarns. All the yarns are divided into 13 layers, represented by 1-13 respectively; all yarn layers are divided into 7 parts, initially according to (1, 2) (3) (4, 5, 6) (7) (8, 9, 10) (11) ( 12, 13) Hanging yarn; according to the hanging yarn combination, weave 6 flower node lengths (the flower node length refers to the length of the prefabricated part woven by one machine cycle) as the starting...

Embodiment 2

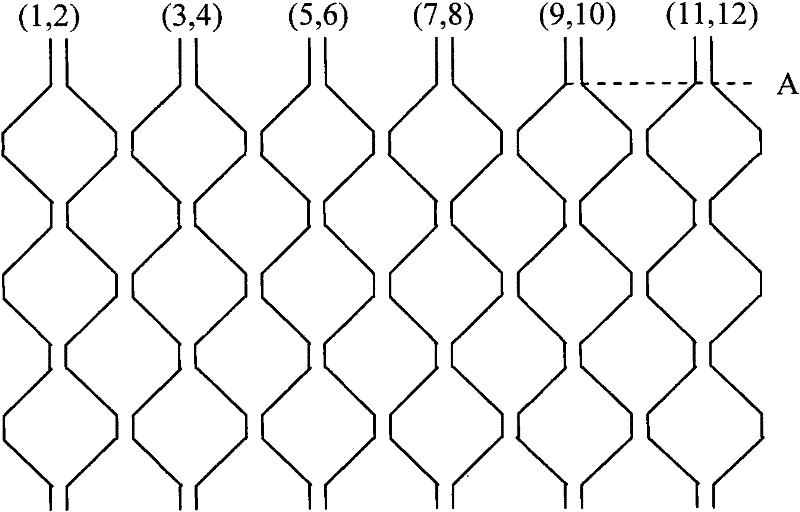

[0035] The weaving method of the prefabricated part whose grid shape is rhombus (see figure 2 with 4 ).

[0036] The diamond grid weaving structure adopts a three-dimensional four-way structure, the weaving yarn is 1200tex glass fiber, and the number of yarns required for weaving is designed to be 720; according to the shape required by the grid, each layer of yarns is designed to be 60, and all yarns The thread is divided into 12 layers, represented by 1-12 respectively; the initial part is weaved according to (1, 2) (3, 4) (5, 6) (7, 8) (9, 10) (11, 12) combination 8 node as the starting position A. Then ①all the yarn layers are separated, and each yarn layer is woven separately, and each yarn layer is woven with 4 flower nodes; ②according to (1)(2,3)(4,5)(6,7)(8 , 9) (10, 11) (12) Combining weaving a flower node, and exchanging part of the yarns between the two connected yarn layers to improve the mechanical properties at the intersection of the grid; ③All the yarn laye...

Embodiment 3

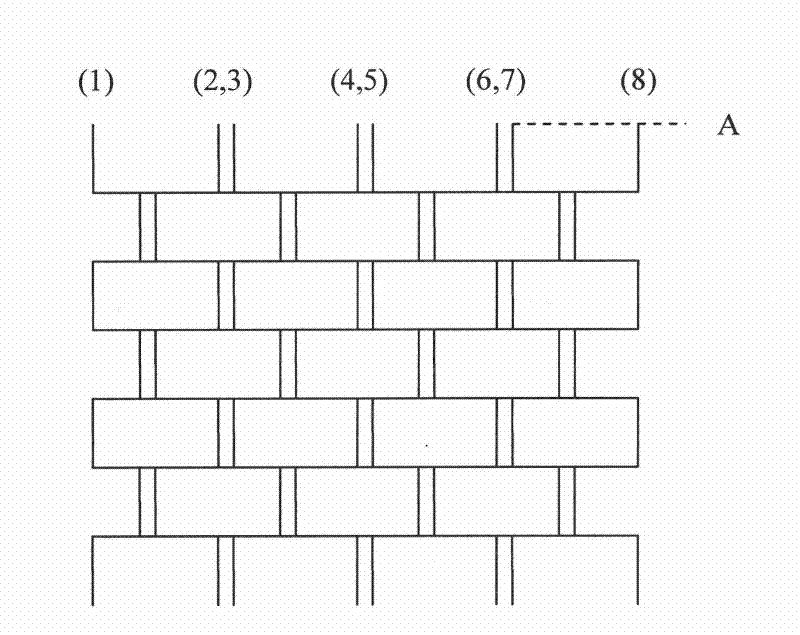

[0038] The weaving method of the prefabricated part whose grid shape is square or rectangular (see figure 2 ).

[0039] The square grid weaving structure adopts a three-dimensional six-way structure, and the weaving yarn is 12K carbon fiber. All the yarns are designed to be divided into 8 layers, which are respectively represented by 1-8. When hanging yarn, according to (1) (2, 3) (4, 5) (6, 7) (8) combination, weave 7 flower node lengths as the starting position A; then ① weave the corresponding length for each yarn layer; ② Combination knitting according to (1, 2) (3, 4) (5, 6) (7, 8); ③ All yarn layers are separated, and each yarn layer is knit separately; ④ Press (1) (2, 3) (4, 5) (6, 7) (8) combined weaving corresponding length. Repeat the above four weaving steps ①~④, and all the weaving yarns participate in weaving until the weaving is finished, and the overall weaving of the square grid prefabricated part is completed. The grid shape of the square prefabricated pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com