Electroplating method of integrated circuit lead frame

A lead frame and integrated circuit technology, which is applied in jewelry and other fields, can solve the problems of large waste of dry film, high cost, and high price of dry film, and achieve the effect of low electroplating cost, which is conducive to mass production and saves consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

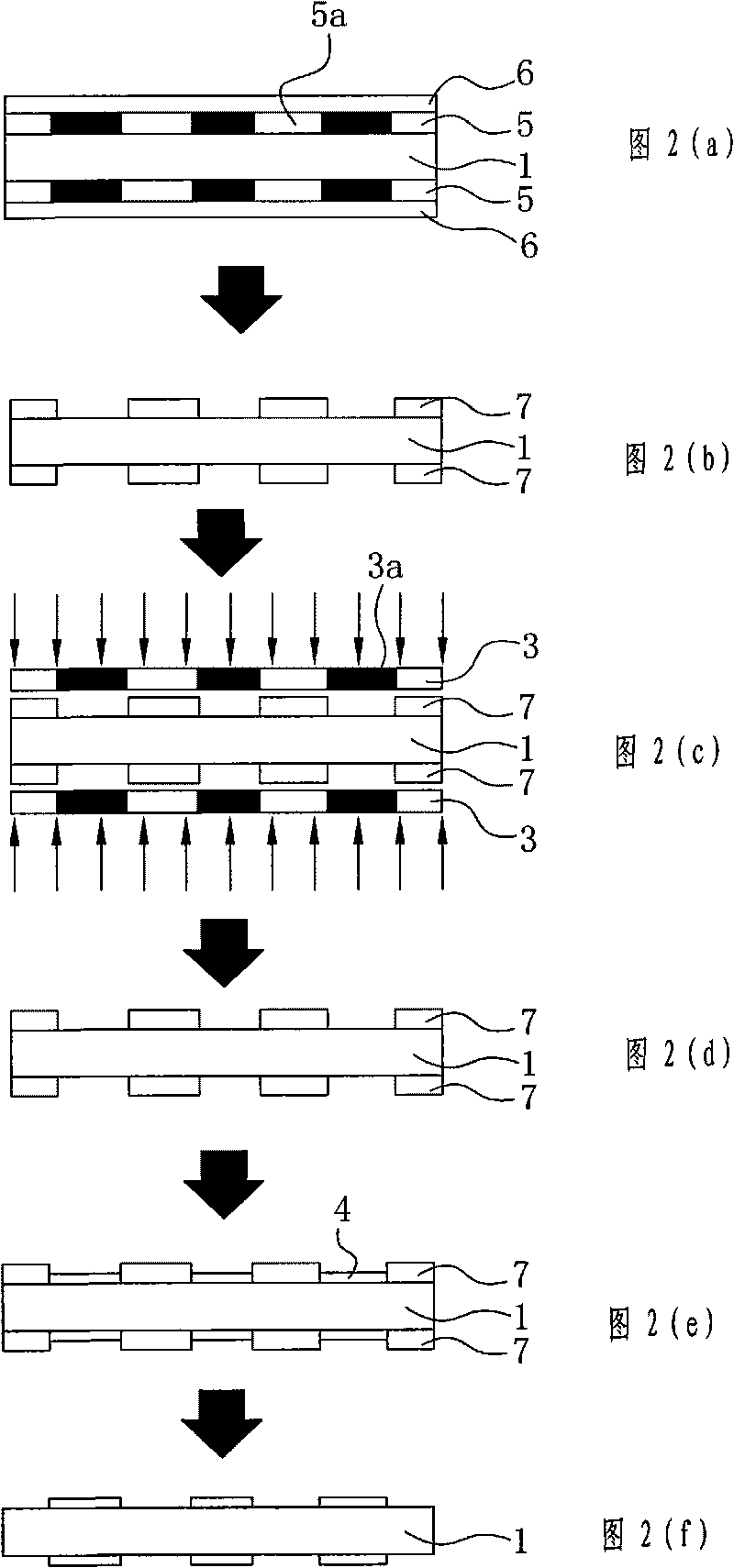

[0025] A kind of electroplating method of integrated circuit lead frame as shown in Figure 2, it comprises the following steps:

[0026] ①. Make the screen printing plate 5 according to the lead frame, and engrave the screen printing plate 5 according to the conventional method;

[0027] ②. Dilute the photosensitive ink 6, the blending ratio of photosensitive ink 6 and diluent is 7:3, the photosensitive ink 6 is photosensitive green oil, photosensitive green oil and diluent are commercially available products, and the diluent is Hong Kong Sun The model produced by Taiyo ink international limited is CA-40 AUS303, and it only needs to be prepared according to the proportion after purchase;

[0028] ③. After the diluted photosensitive ink 6 is spread over the upper surface of the screen printing plate 5, as shown in Figure 2 (a), the lead frame 1 is double-sided printing plate, as shown in Figure 2 (b) on the lead frame 1 Partial areas of the upper and lower surfaces of the ink ...

Embodiment 2

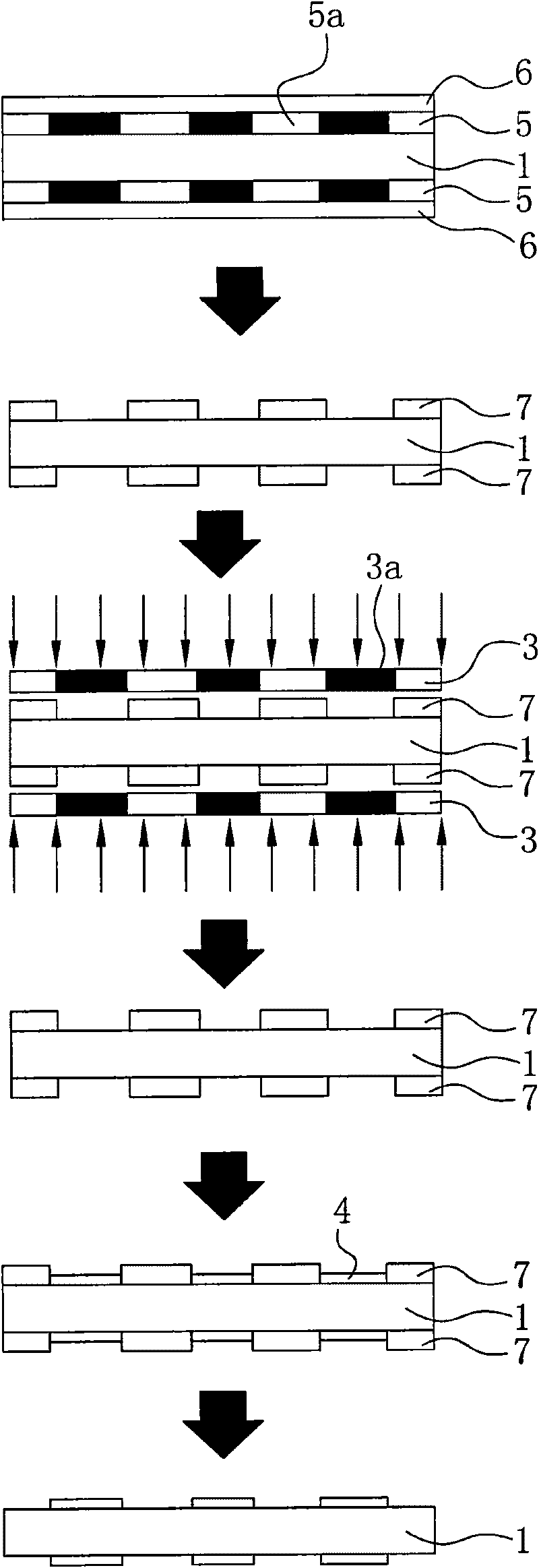

[0036] A kind of electroplating method of integrated circuit lead frame as shown in Figure 2, it comprises the following steps:

[0037] ①. Make the screen printing plate according to the lead frame, and engrave the screen printing plate 5 according to the conventional method;

[0038] ②. Dilute the photosensitive ink 6, the blending ratio of photosensitive ink 6 and diluent is 7:3, the photosensitive ink 6 is photosensitive green oil, photosensitive green oil and diluent are commercially available products, and the diluent is Hong Kong Sun The model produced by Taiyo ink international limited is CA-40 AUS303, and it only needs to be prepared according to the proportion after purchase;

[0039] ③. After the diluted photosensitive ink 6 is spread over the upper surface of the screen printing plate 5, as shown in Figure 2 (a), the lead frame 1 is double-sided printing plate, as shown in Figure 2 (b) on the lead frame 1 Partial areas of the upper and lower surfaces of the ink fi...

Embodiment 3

[0047] A kind of electroplating method of integrated circuit lead frame as shown in Figure 2, it comprises the following steps:

[0048]①. Make the screen printing plate according to the lead frame, and engrave the screen printing plate 5 according to the conventional method;

[0049] ②. Dilute the photosensitive ink 6, the blending ratio of photosensitive ink 6 and diluent is 7:3, the photosensitive ink 6 is photosensitive green oil, photosensitive green oil and diluent are commercially available products, and the diluent is Hong Kong Sun The model produced by Taiyo ink international limited is CA-40AUS303, and it only needs to be prepared according to the proportion after purchase;

[0050] ③. After the diluted photosensitive ink 6 is spread over the upper surface of the screen printing plate 5, as shown in Figure 2 (a), the lead frame 1 is double-sided printing plate, as shown in Figure 2 (b) on the lead frame 1 Partial areas of the upper and lower surfaces of the ink film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com