Method for preparing butanedioic acid through fermentation

A technology of succinic acid and anaerobic fermentation, applied in the field of bioengineering, can solve the problems of increasing the difficulty of separation and extraction of downstream products, unfavorable industrial production of succinic acid biological method, large consumption, etc. Technical effect, effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for preparing succinic acid described in the present invention can use any anaerobic fermentation microbial strain producing succinic acid in the prior art. The succinic acid-producing microbial strain used in this example is: Actinobacillus succinogenes NJ113 (Actinobacillus succinogenes NJ113). This bacterium has applied for a patent and obtained authorization, and the patent authorization announcement number is CN100537744C.

[0032] The fermentation medium of the present invention can use any fermentation medium for producing succinic acid by anaerobic fermentation in the prior art. The medium used in this example is: every liter of volume medium contains 50-100 g of glucose (sterilized separately), 15 g of yeast powder, 15 mL of corn steep liquor, 1.36 g of anhydrous sodium acetate, 1 g of NaCl, K 2 HPO 4 3g, MgCl 2 0.2g, CaCl 2 0.2g.

[0033] The method for preparing succinic acid by fermenting microbial strains of the present invention can be any...

Embodiment 2

[0043] The present embodiment adopts the same fermentation conditions and methods as in Example 1, only changing the method of adding alkaline neutralizing agent separately in the step of producing succinic acid as follows:

[0044] Add Ca(OH) separately 2 and CaCO 3 As an alkaline neutralizing agent to adjust the pH value.

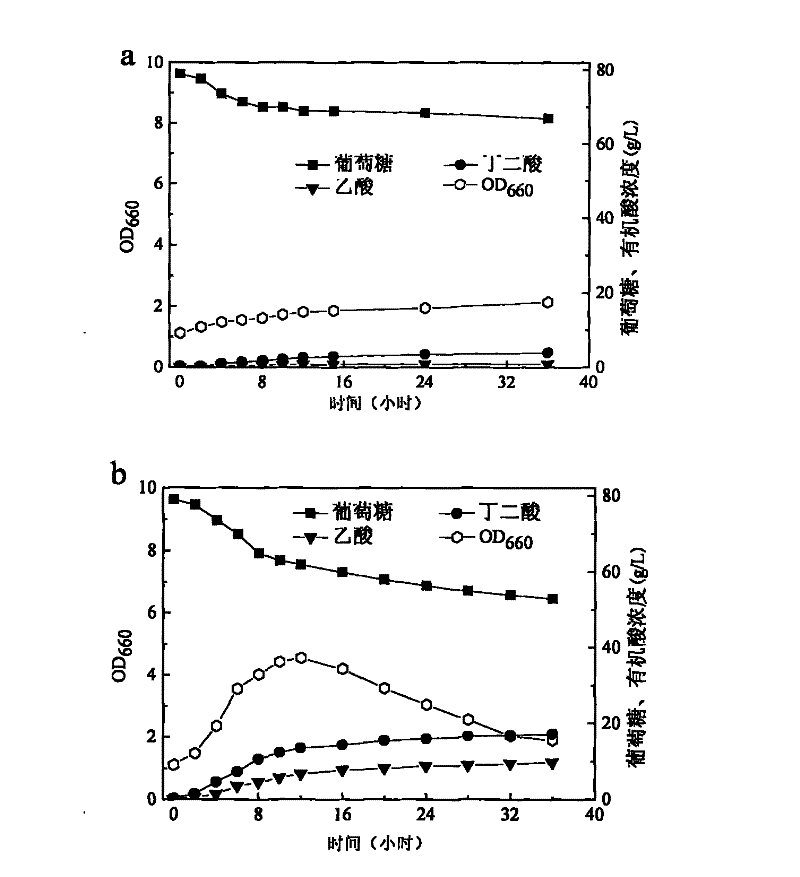

[0045] Ca(OH) was used separately in the fermenter 2 , CaCO 3 Adjust the pH to ferment, the results are shown in figure 2 shown. Using Ca(OH) 2 Regulated, the thalline hardly grows, and the mass concentration of succinic acid is less than 5g / L ( figure 2 -a). CaCO 3 Solids adjust the pH of fermentation, and the growth ratio of bacteria is Ca(OH) 2 Slightly better when conditioning fermentation, but still noticeably inhibited. CaCO 3 The dissolving power of the bacterium is relatively poor, and the pH cannot be maintained at a level suitable for the growth of the thallus. During the fermentation process, the pH constantly decreases, and to the...

Embodiment 3

[0047] The present embodiment adopts the same fermentation conditions and methods as in Example 1, only changing the method of adding alkaline neutralizing agent separately in the step of producing succinic acid as follows:

[0048] Add NaOH, Na 2 CO 3 , NaHCO 3 As an alkaline neutralizing agent to adjust the pH value.

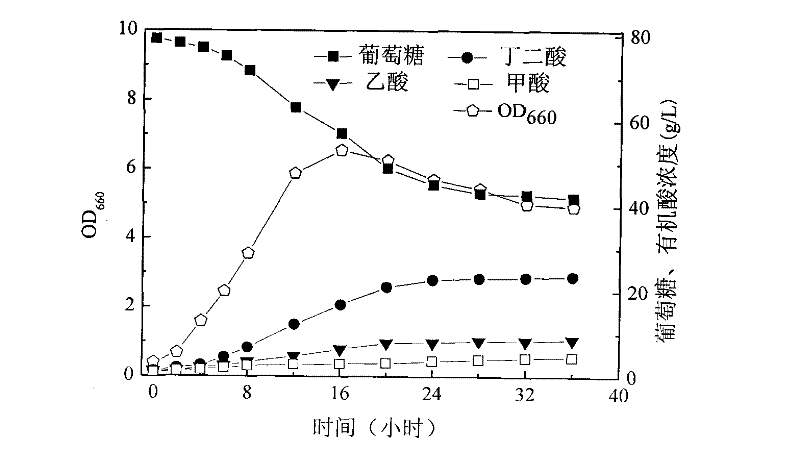

[0049] Feed NaOH, Na 2 CO 3 , NaHCO 3 The way to adjust the pH, the fermentation results are as follows image 3 shown. With Na + Continuously accumulating in the fermentation broth, the bacteria flocculation phenomenon is serious in the middle and late stages of fermentation, and the bacteria OD 660 There was an obvious downward trend, and the rate of sugar consumption gradually slowed down. NaOH and Na 2 CO 3 , NaHCO 3 Compared to the end of fermentation, the residual amount of glucose was more, and the mass concentration of succinic acid was 43.5g / L ( image 3 -a). Na 2 CO 3 , NaHCO 3 able to provide additional CO 3 2- 、HCO 3 - , which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com