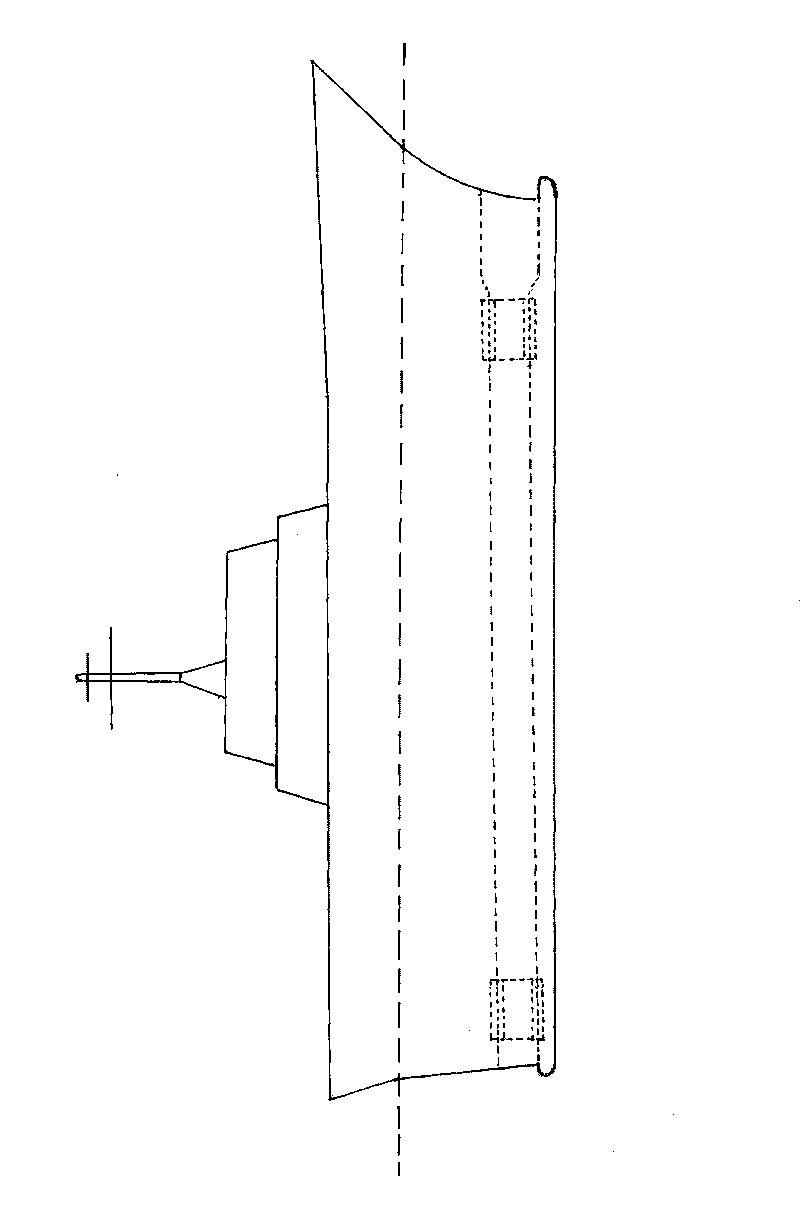

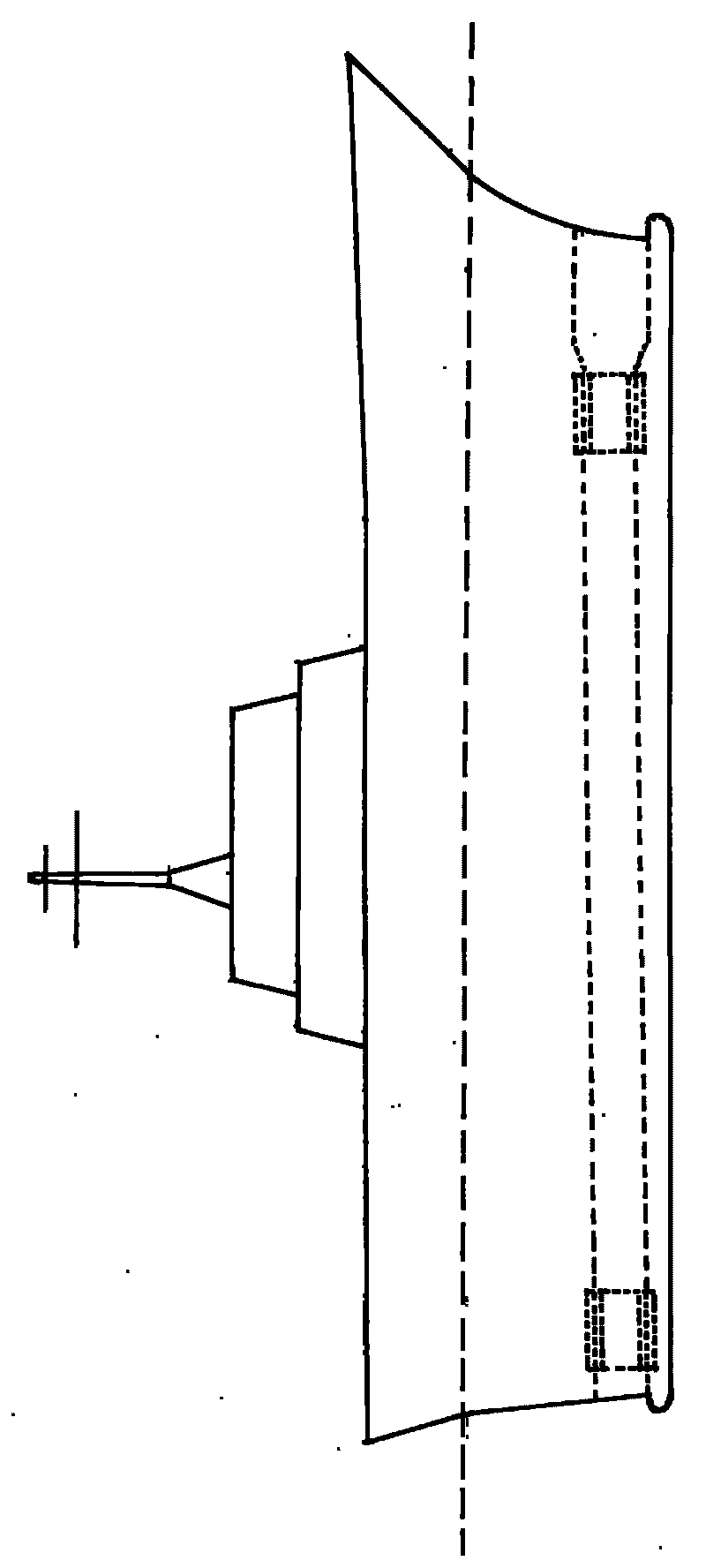

Water-swallow ship form

A technology of ship shape and water flow, applied in the direction of hull, ship propulsion, ship parts, etc., to achieve the effect of speeding up the advance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] 1. A railing should be properly set up at the water swallowing port of the bow to prevent larger debris or organisms in the water from being swallowed, resulting in pipeline blockage.

[0013] 2. The ratio of the hollow diameter of the water accelerator drum to the inner diameter of the drum should not be too small, and the casualties of creatures swallowed into the water should be minimized.

[0014] 3. There are several blade-type spiral grooves in the drum of the water accelerator, which can be designed to rotate the drum by mechanical transmission, or it can be designed as the rotor of the motor. Of course, if there are other more advanced and reasonable methods, feel free to adopt them.

[0015] 4. The center line of the water flow pipe should be roughly parallel to the bottom of the ship, or the rear side should be inclined downward appropriately.

[0016] 5. The "water-swallowing ship type" is designed to use the water spray at the outlet of the water flow pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com