Method for assembling gear set and special tool thereof

An assembly method and technology of a gear set, applied in the field of mechanical transmission, can solve problems such as inconvenience, and achieve the effects of reducing testing and manufacturing costs, reducing functional requirements, and simplifying technological processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, the assembly of a gear set composed of two large and small gears is taken as an example.

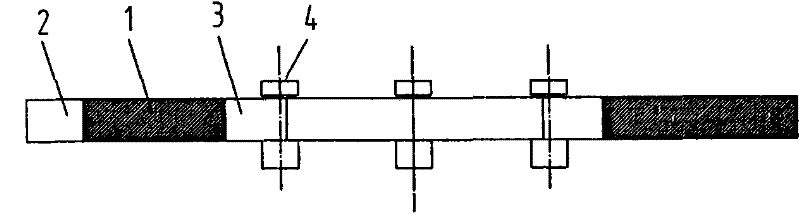

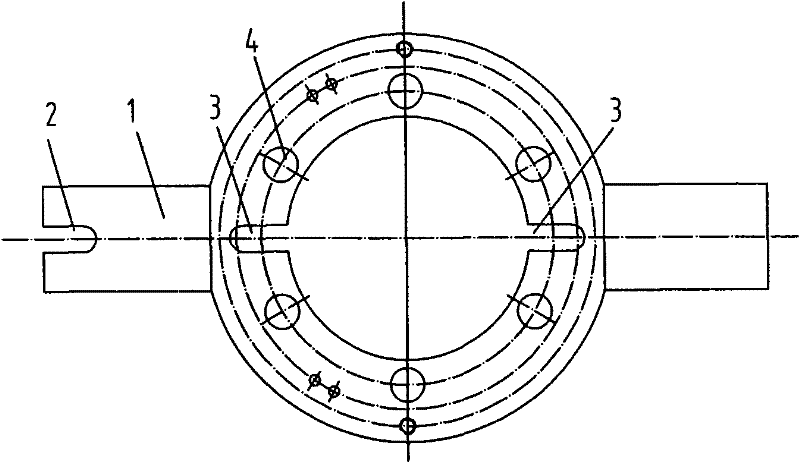

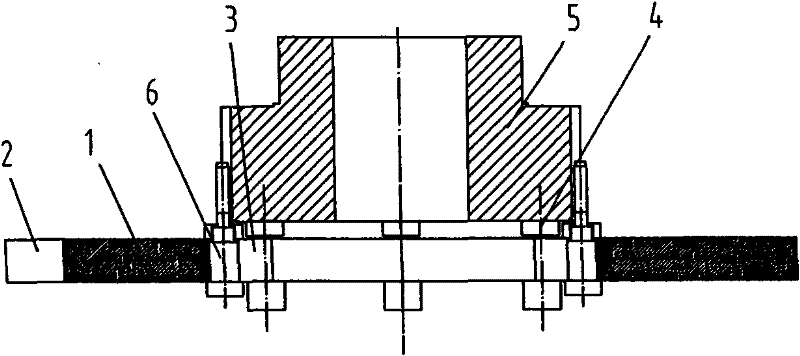

[0021] Make special tooling first, such as figure 1 and figure 2 As shown, the main body of the seat body 1 with the axis of the gear to be assembled as the center of the special tooling is in the shape of a ring, and extension arms extend from both sides of the ring body. There are a pair of radially extending first positioning grooves 3 near the position corresponding to the small (first) gear indexing circle on both sides of the center of the annular main body, and a pair of radially extending first positioning grooves 3 are formed on one of the extension arms corresponding to the large (second) gear indexing A second positioning groove 2 extending radially is opened at the circle position. The angular position of the first positioning groove and the second positioning groove corresponds to the angular position of the assembled first gear and the second g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com