Brushless direct-current motor and circuit board quick connecting device

A technology of brush DC motor and quick connection, which is applied in the direction of electromechanical devices and electrical components, can solve the problems of low production efficiency, high production cost, increased manpower and process cost, etc., and achieve the effect of improving production and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

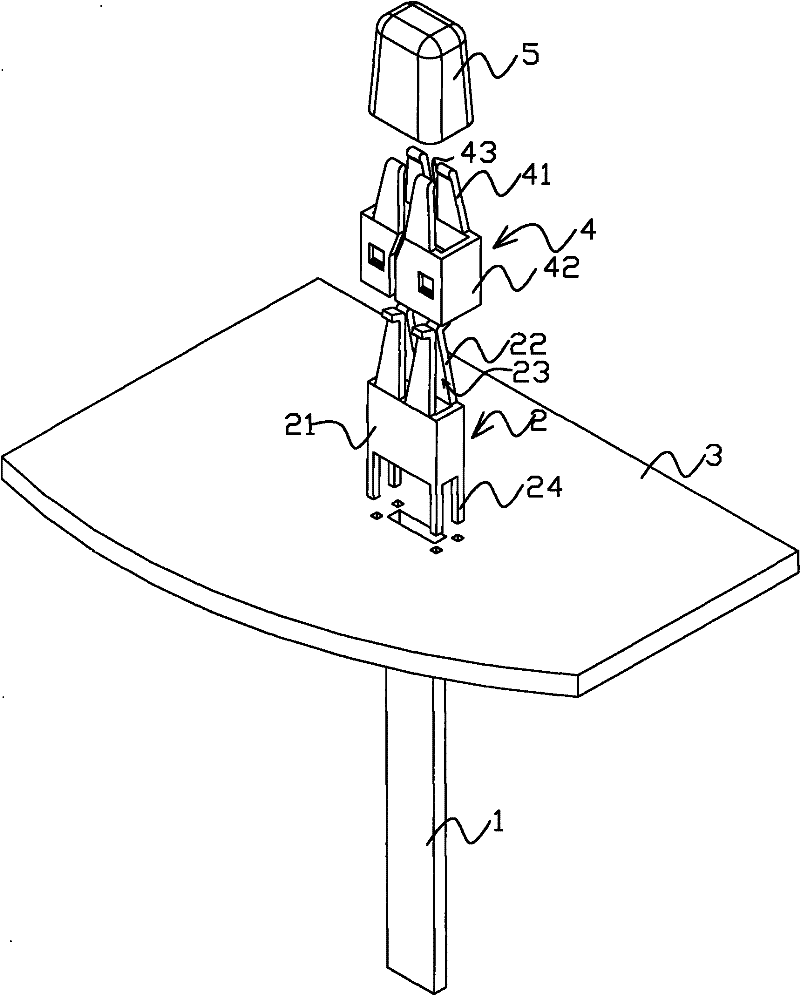

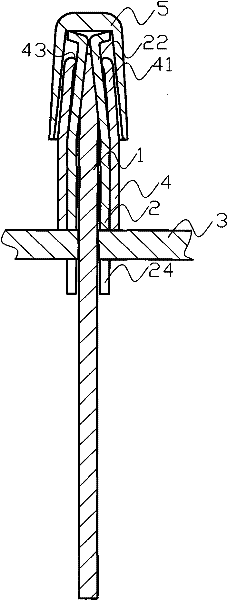

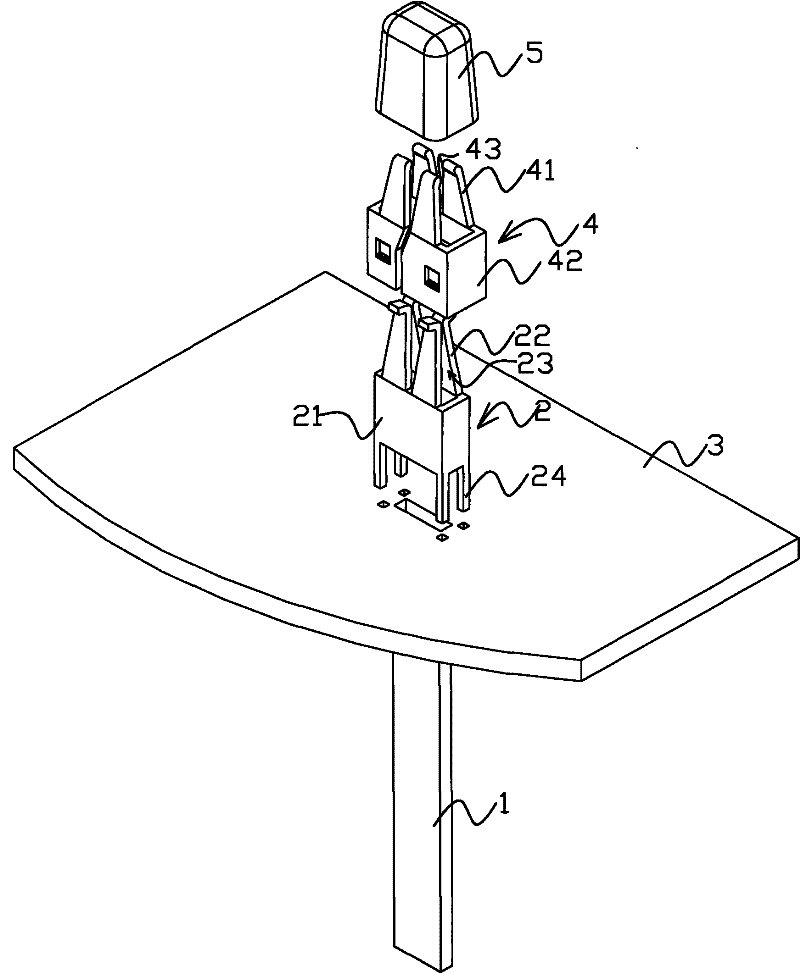

[0019] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 , 2 As shown, the present invention includes a strip-shaped conductive pin 1 electrically connected to the motor winding, and a connector 2 fixed on the circuit board 3 that cooperates with the conductive pin 1. The connector 2 includes a connecting seat 21 and is located on the connecting seat 21. The four "7"-shaped metal shrapnel 22 that can hold the conductive pin 1, the four shrapnel 22 are symmetrically arranged on the connecting seat 21, and the inner walls thereof are combined to form a socket cavity 23 with a lower size and an upper size to cooperate with the conductive pin 1, In order to increase the contact surface, the head of the conductive pin 1 has a bevel; in order to increase the strength of the elastic piece 22 and prevent excessive deformation, a limiter 4 is provided on the outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com