One-way transmission device with coupling

A technology of one-way transmission and coupling, applied in the direction of clutches, mechanical equipment, etc., can solve the problems of restricting reliability and service life, load or prime mover impact, reducing the life of the transmission unit, etc., to improve the efficiency of mechanical transmission and reduce the The effect of low vibration level, reducing vibration and noise, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

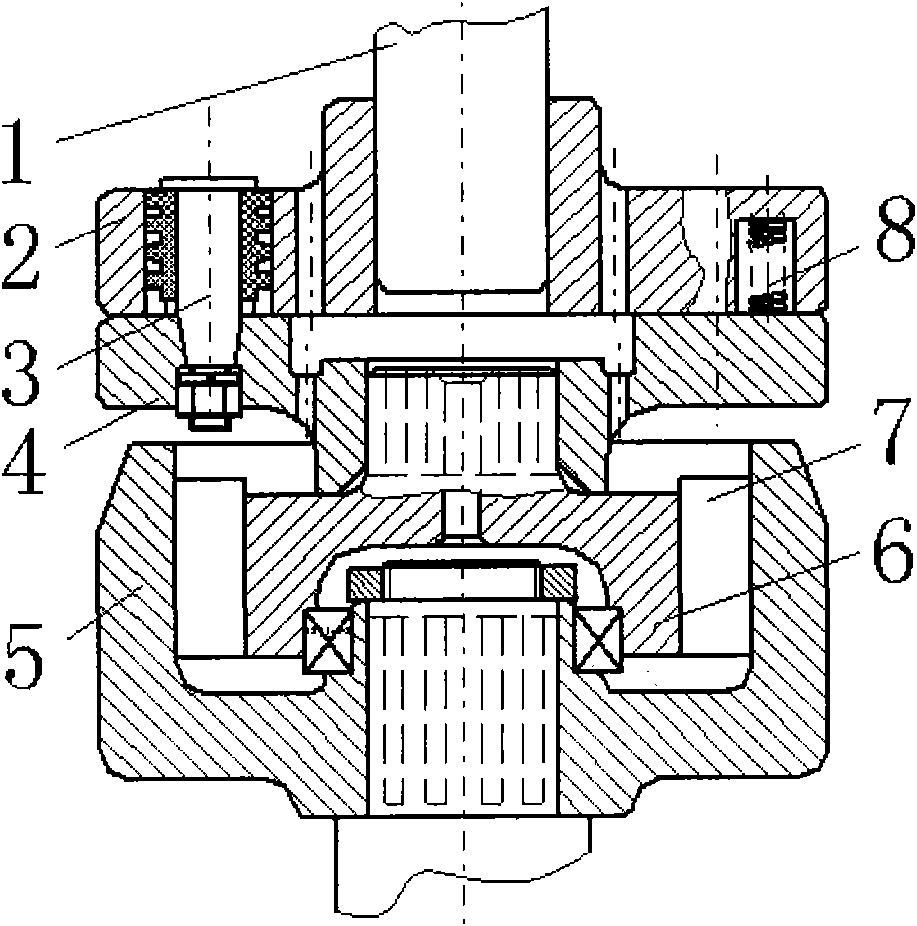

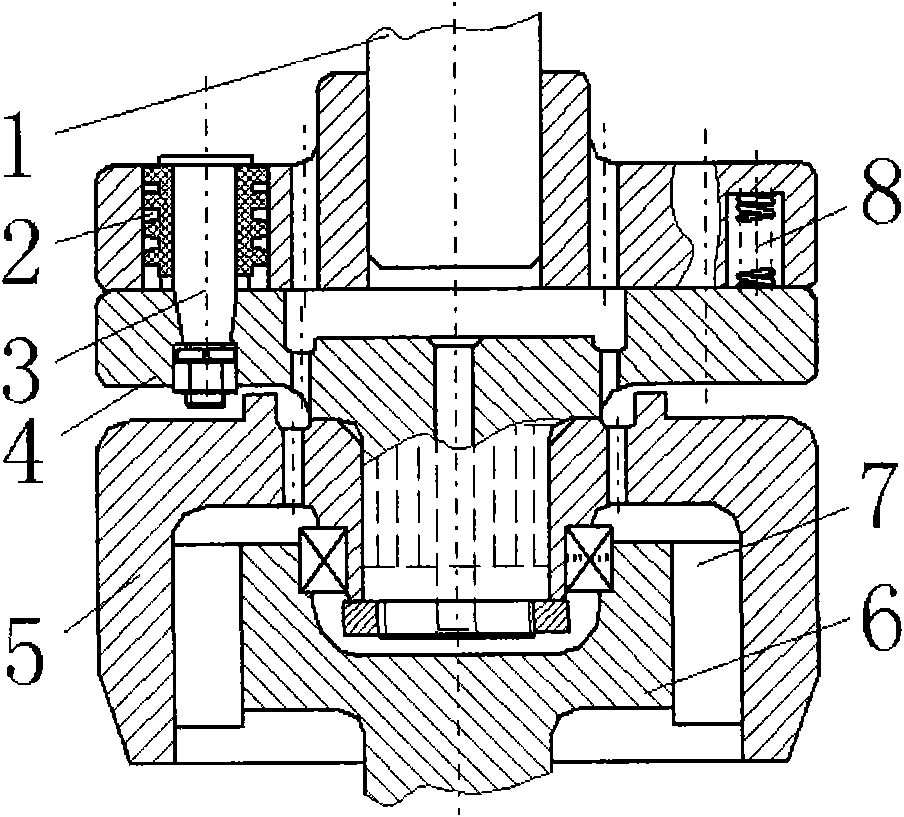

[0018] In Embodiment 1, the half coupling 2 is connected with the prime mover input shaft 1, the outer race 5 is connected with the power output shaft, and the half coupling 4 and the inner race 6 are connected by keys. The prime mover output shaft 1 drives the half-coupling 2 to rotate. The half-coupling 2 drives the half-coupling 4 and the inner race 6 to rotate through 4-8 sets of elastic element components and 2-6 sets of compression springs, through the middle piece 7 The torque is transmitted by the action of the outer race 5, and the errors caused by manufacturing and assembly are compensated by elastic elements and compression springs. When the unit starts and stops, the continuous rotation of the output shaft will not affect the prime mover.

Embodiment 2

[0019] In Embodiment 2, the half coupling 2 is connected with the prime mover input shaft 1, the inner race 6 is connected with the power output shaft, and the half coupling 4 and the outer race 5 are connected by keys. The prime mover input shaft 1 drives the half-coupling 2 to rotate. The half-coupling 2 drives the half-coupling 4 and the outer race 5 to rotate through 4-8 sets of elastic element components and 2-6 sets of compression springs, through the middle piece 7 The torque is transmitted by the action of the inner race 6 and the errors caused by manufacturing and assembly are compensated by elastic elements and compression springs. When the unit starts and stops, the continuous rotation of the output shaft will not affect the prime mover.

[0020] The lubricating oil circuit of the two schemes is divided into two parts at the same time. One part passes through the circumferentially arranged oil holes of the lower half coupling 4 to lubricate the intermediate piece 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com