Floating connection device between hydraulic power unit gear box and oil pump for engineering ship

A hydraulic pump station and coupling device technology, which is applied in infrastructure engineering, couplings, motor vehicles, etc., can solve the misalignment of the output shaft of the gearbox of the hydraulic pump station and the shaft of the high-pressure oil pump group, damage to the spline teeth of the hydraulic oil pump, and all In order to solve the problems such as the failure of normal construction of the ship, it can achieve the effect of easy guarantee of processing accuracy, convenient lubrication and cooling, and easy guarantee of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

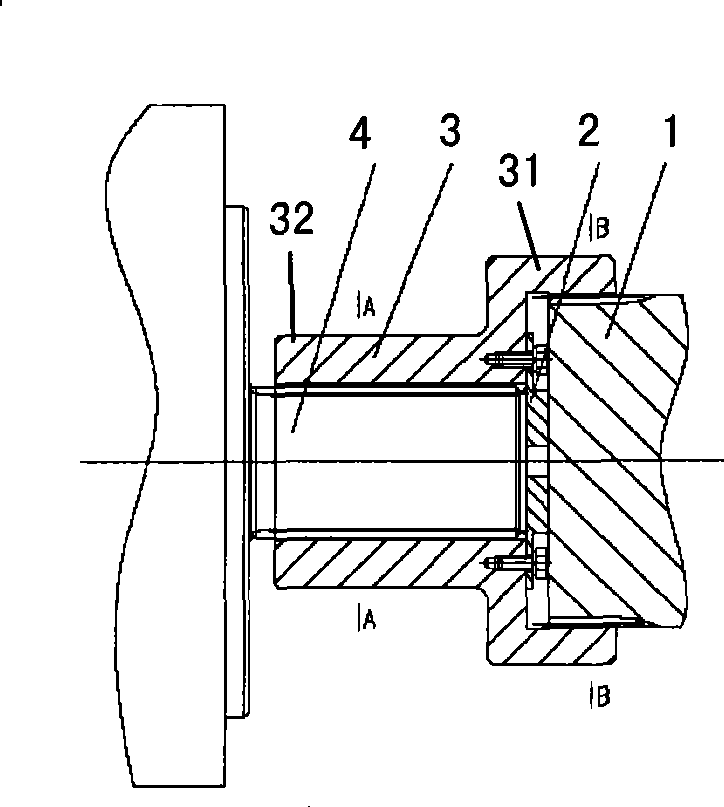

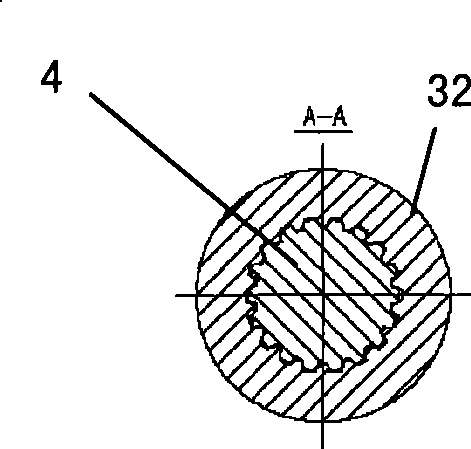

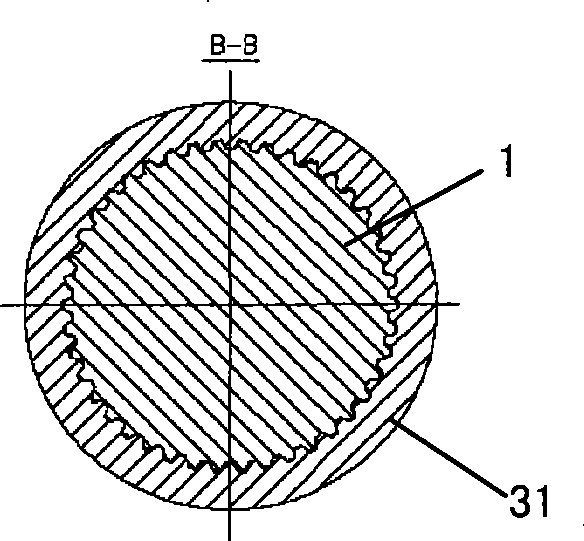

[0019] Also refer to figure 1 , figure 2 and image 3 , An embodiment of the present invention includes a gearbox output shaft head 1, a baffle plate 2, a floating spline sleeve 3 and an oil pump shaft head 4.

[0020] The gearbox output shaft head 1 has external splines, and the oil pump shaft head 4 also has external splines. The floating spline sleeve 3 includes a first key sleeve 31 and a second key sleeve 32, and the first key sleeve 31 and the second key sleeve 32 are connected. The first key casing 31 and the second key casing 32 are respectively formed with internal splines. The spline parameters of the first key sleeve 31 correspond to the spline parameters of the external splines of the output shaft head 1 of the gearbox, and the spline parameters of the second key sleeve 32 correspond to the spline parameters of the external splines of the oil pump shaft head 4 . The first key sleeve 31 of the floating spline sleeve 3 is splined to the gearbox output shaft hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com