Lubricant dispersant

A lubricating oil dispersant and glycerin technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of black sludge dispersion and poor adsorption, achieve effective adsorption and control, good peptization and dispersion, and reduce the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Add 26.7g (about 0.12mol) phosphorus pentasulfide, 0.9g sulfur powder and 2000g toluene to 420g (number average molecular weight about 4200, about 0.1mol) polyisobutylene, heat up to 120-150°C, reflux for 6 hours;

[0014] (2) Maintain the above reaction solution at 170~180℃, bubbling with 100℃ water vapor for 10 hours, and cool to 50~60℃ to obtain about 500g solution, and then use 700g absolute ethanol at 50~60℃ to extract 6 Hours, remove the upper liquid layer by layer;

[0015] (3) Add 9.2g (about 0.1mol) of glycerol and 31.8g (about 0.3mol) of xylene to the lower layer liquid obtained in step (2), heat to 160~180℃, reflux for 4 hours, and distill off the xylene to obtain The lubricant dispersant A of the present invention.

Embodiment 2

[0017] (1) Add 22.2g (about 0.1mol) phosphorus pentasulfide, 0.74g sulfur powder and 1500g toluene to 350g (number average molecular weight about 3500, about 0.1mol) polyisobutylene, heat up to 120~150℃, reflux for 6 hours, and steam Toluene

[0018] (2) Maintain the above reaction solution at 170~180℃, bubbling with 100℃ water vapor for 10 hours, and cool to 50~60℃ to obtain about 420g solution, and then use 500g absolute ethanol at 50~60℃ to extract 6 Hours, remove the upper liquid layer by layer;

[0019] (3) Add 11g (about 0.12mol) of glycerin and 31.8g (about 0.3mol) of xylene to the lower liquid obtained in step (2), heat to 160~180℃ and reflux for 4 hours, and distill off the xylene to obtain the product Invented lubricant dispersant B.

Embodiment 3

[0021] (1) Add 0.45g sulfur powder and 1200g toluene to 215g (number average molecular weight about 2150, about 0.1mol) polyisobutylene and 17.8g (about 0.08mol) phosphorus pentasulfide, heat up to 120~150℃, reflux for 6 hours;

[0022] (2) Maintain the above reaction solution at 170~180℃, bubbling with 100℃ water vapor for 10 hours, and cool to 50~60℃ to obtain about 280g solution, and then use 350g absolute ethanol to extract 6 at 50~60℃. Hours, remove the upper liquid layer by layer;

[0023] (3) Add 13.8g (about 0.15mol) of glycerin and 31.8g (about 0.3mol) of xylene to the lower layer liquid obtained in step (2), heat to 160~180℃, reflux for 4 hours, and distill off the xylene to obtain Lubricating oil dispersant C of the present invention.

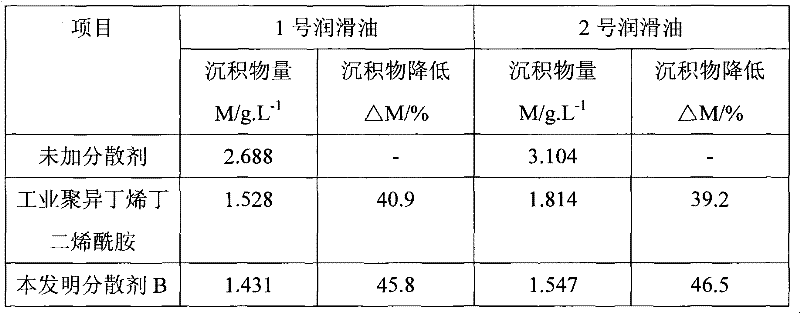

[0024] Lubricating oil will accelerate oxidation when it is used under heating. The result of oxidation is the formation of deposits on the reactor wall. The deposits are mainly carbon deposits. The deposition amount M per unit volume of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com