Method for pre-oxidizing oil field waste water by using air

A technology for pre-oxidation treatment and oilfield sewage. It is applied in the directions of oxidized water/sewage treatment, mining wastewater treatment, etc. It can solve problems such as power consumption and danger, and achieve the effects of easy regulation, simple operation, and easy promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment adopts the method of the present invention alone, utilizes air to carry out preoxidation to oil field sewage, and sewage flow rate is 238m 3 / h, the air is pressed into the sewage treatment process with an air compressor. Air forms free oxygen or dissolved oxygen in oilfield sewage; using the oxidation ability of free oxygen or dissolved oxygen, ferrous ions in oilfield sewage are oxidized into iron ions, and iron ions are hydrolyzed to form Fe x (OH) m (3x-m)+ Colloidal precipitation, while oxidizing sulfide to elemental sulfur; elemental sulfur is then removed by flocculation, sedimentation and filtration.

[0032] The water quality in the station and the wellhead water quality were monitored, and the results are shown in Table 1.

[0033] The result in the embodiment 1 of table 1

[0034]

[0035]

[0036] As can be seen from Table 1, the method of the present invention can not only treat the sewage into the up-to-standard inje...

Embodiment 2

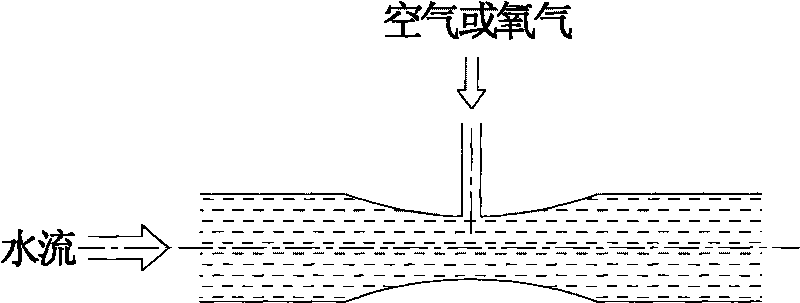

[0038] In this example, the electrochemical method and the combined method of air and electrochemistry are used to treat oilfield sewage, and the sewage flow rate is 154m 3 / h. The current consumption required by the electrochemical method is 5760A; the method of combining air and electrochemistry is used, that is, the air is first sucked into the sewage treatment system by using the Venturi principle, and then the electrochemical method is used for "pre-oxidation", and the required current is only 295A is required.

[0039] The air and the anode will reduce the reducing substances in the sewage, such as H 2 S, HS - , S 2- , Fe 2+ and FeS etc. oxidized to colloidal Fe x (OH) (3x-m) m+ and elemental S, the bacteria were completely killed, followed by flocculation, sedimentation, and filtration to monitor the water quality in the station and the wellhead water quality, the results are shown in Table 2:

[0040] Table 2 Example 2 Experimental Results

[0041]

...

Embodiment 3

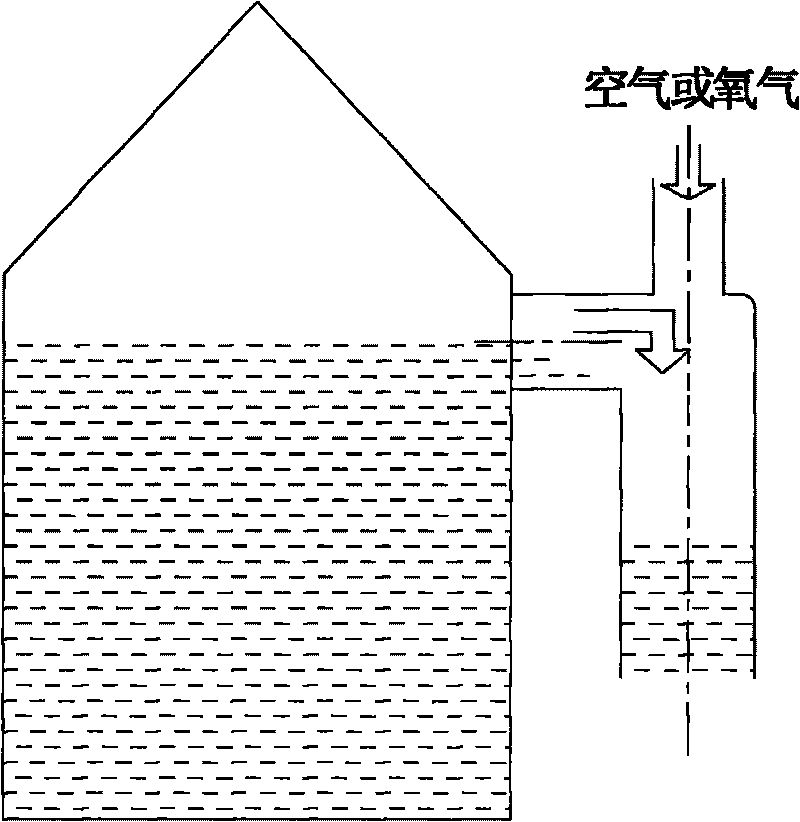

[0044] In this example, the chemical method and the combination of air and chemistry are used to treat oilfield sewage, and the sewage flow rate is 338m 3 / h. The chemical method needs to consume 12.19kg of KClO per hour 3 ;Adopt the method of combining air and chemistry, that is, first use the impact force of the settling tank to overflow to carry the air into the sewage treatment system, and then use chemical methods to carry out "pre-oxidation", the KClO that needs to be consumed 3 Only 0.455kg.

[0045] Air and chemical oxidants will reduce the reducing substances in sewage, such as H 2 S, HS - , S 2- , Fe 2+ and FeS etc. oxidized to colloidal Fe x (OH) (3x-m) m+ and elemental S, the bacteria were completely killed, followed by flocculation, sedimentation, and filtration to monitor the water quality in the station and the wellhead water quality, and the results are shown in Table 3:

[0046] Table 3 Example 3 Experimental Results

[0047]

[0048] It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com