Fixed releasing device of greenhouse high tunnel plastic film

A plastic film and greenhouse technology, which is applied in greenhouse cultivation, agricultural machinery and equipment, climate change adaptation, etc., can solve the problems of lack of release function, etc., and achieve the effect of simple structure, time-saving and labor-saving operation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

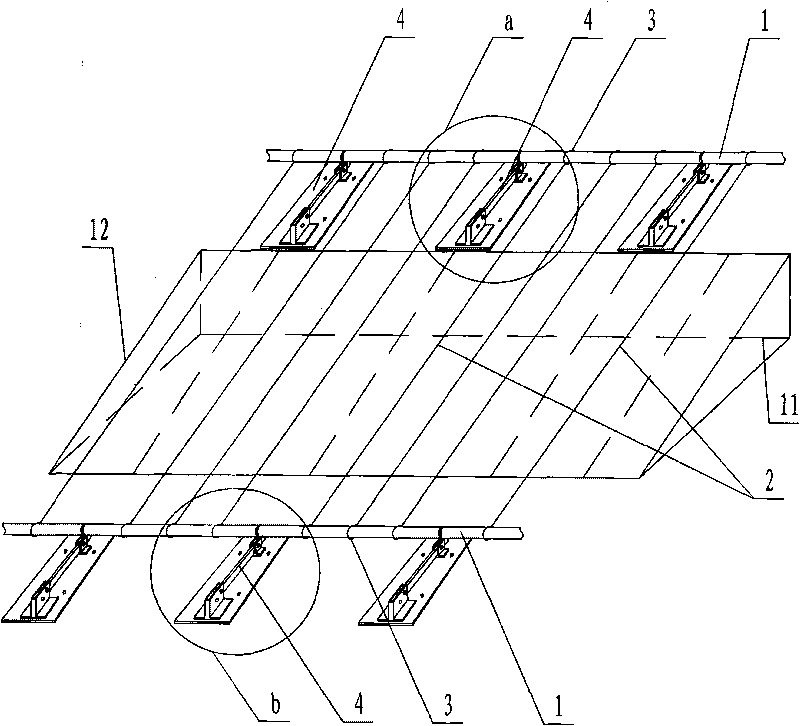

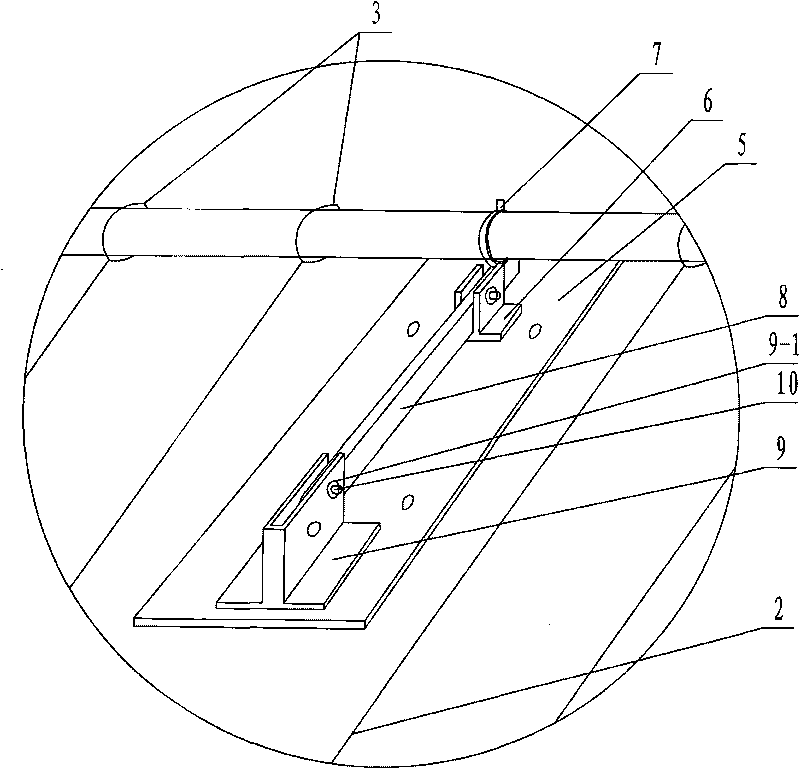

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, the fixing and releasing device of the greenhouse plastic film of this embodiment is made up of two steel pipes 1, a plurality of ropes 2, a plurality of pull rings 3 and at least two groups of fixed releasers, and at least two groups of fixed releasers are arranged side by side Set, each set of fixed releasers is composed of two fixed releasers 4, the two fixed releasers 4 are arranged in the same direction, each fixed releaser 4 includes a base 5, a positioning seat 6, a steel pipe fixing ring 7, and a pull rod 8 and the rod seat 9, the rod seat 9 and the positioning seat 6 are fixed on the base 5 along the length direction of the base 5, one end of the rod 8 is mounted on the rod seat 9 in rotation, and the other end of the rod 8 is installed on the positioning On the seat 6, the steel pipe fixing ring 7 is installed on the end of the pull rod 8 close to the positioning seat 6. A...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 2 ~ Figure 4 To illustrate this embodiment, each fixed release device 4 of this embodiment is also increased with a limit pin 10, and a pin hole 9-1 is opened on the tie rod seat 9, and the pin hole 9-1 is opened on the tie rod seat 9 and positioned close to it. On one end of the seat 6, the limit pin 10 is installed in the pin hole 9-1. Arranged in this way, the limit pin 10 is used to prevent the pull rod 8 from lying down automatically when the pull rod 8 stands up. Other compositions and connections are the same as in the first embodiment.

[0009] The working principle of the fixed release device of the present invention is as follows (see Figure 1 ~ Figure 4 ): a fixed release device 4 of the present invention is installed on the back wall edge of the plastic greenhouse 11, and another fixed release device 4 is installed on the lower foot of the plastic greenhouse 11, and the pull rod 8 is laid down, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com