Electrical heating controller for welding part

An electric heating and controller technology, which is applied in auxiliary controllers with auxiliary heating devices, non-electric variable control, temperature control, etc., can solve the problems of difficult maintenance, complicated electrical circuits, and many electrical control devices, and achieve The effect of improving temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

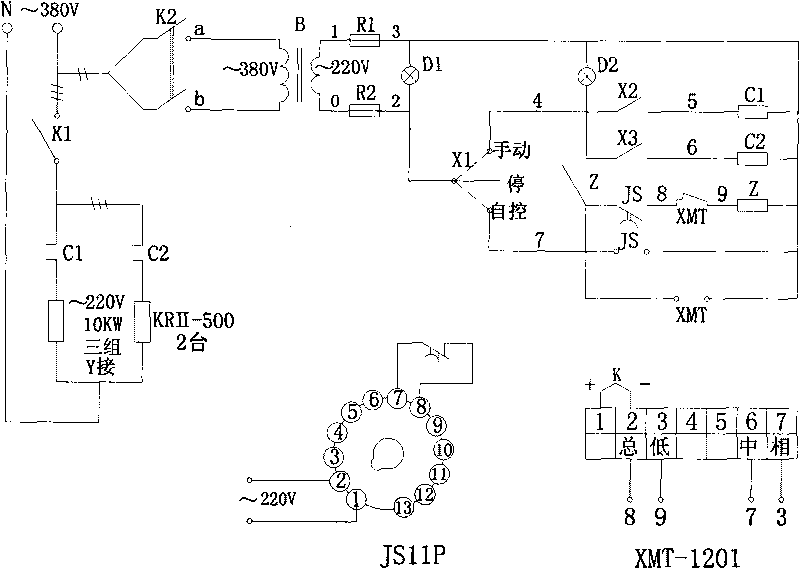

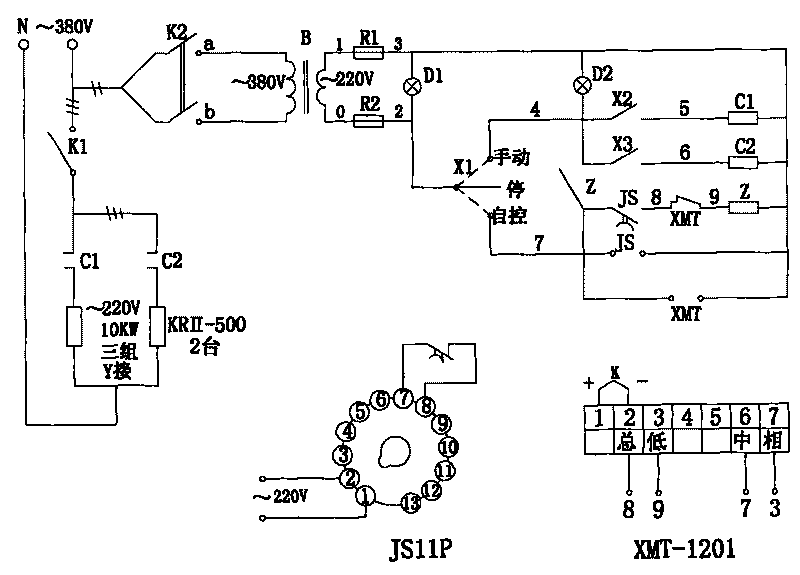

[0024] An electric heating controller for welding parts, which is characterized in that the electric heating controller circuit is connected with a digital display temperature controller, a time relay and a digital display regulator; the digital display temperature controller and the time relay are connected to control the power supply heating circuit, and the digital display temperature The controller is connected with a thermocouple temperature sensor, and the digital display regulator is connected with a digital display temperature controller. The power supply heating circuit is connected with the far-infrared electric heating sheet. The electric heating controller is equipped with automatic recorder, alarm instrument and printer.

[0025] The specific structure of the weldment electric heating controller in this embodiment:

[0026] 1. Circuit of electric heating controller

[0027] Close the air switch K1, the upper port power of the contactors C1 and C2 is turned on; c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com