Heating element, device, and method for resistance welding of thermoplastic components, in particular for the production of aircraft, and aircraft

A heating element and resistance welding technology, which is applied in the field of aircraft, can solve problems such as uneven welding joints, inefficient heating process, and current loss, and achieve the effects of minimizing power loss, reducing power consumption, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

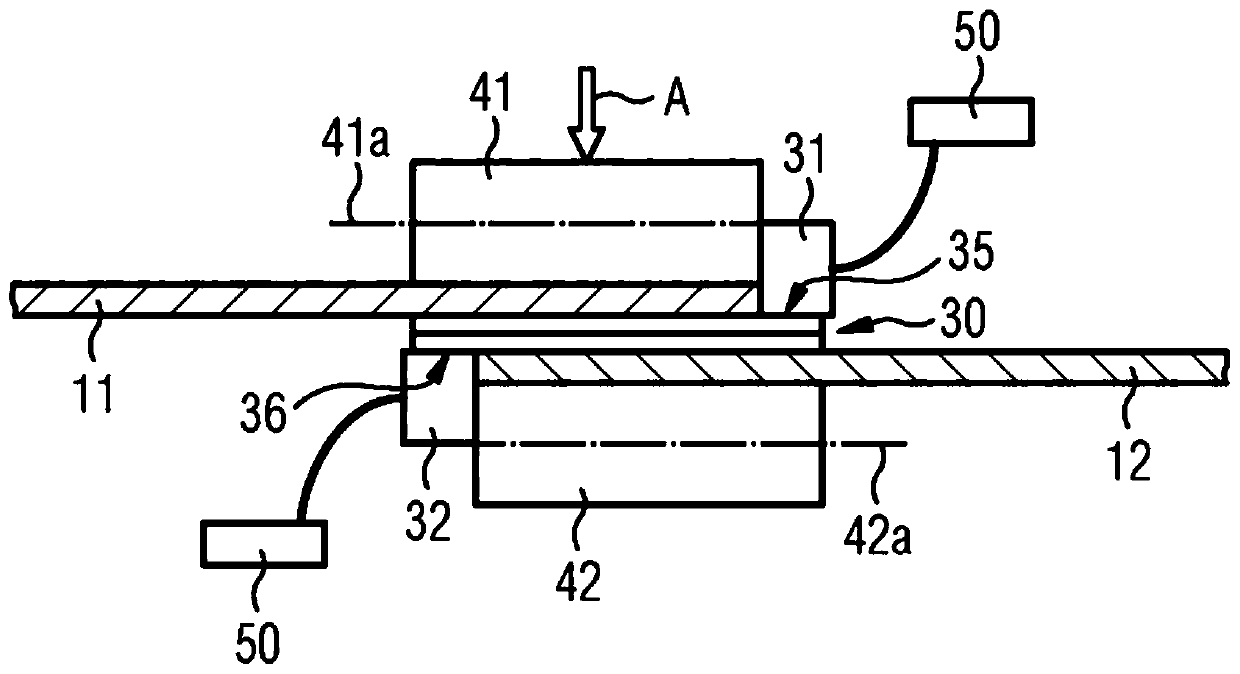

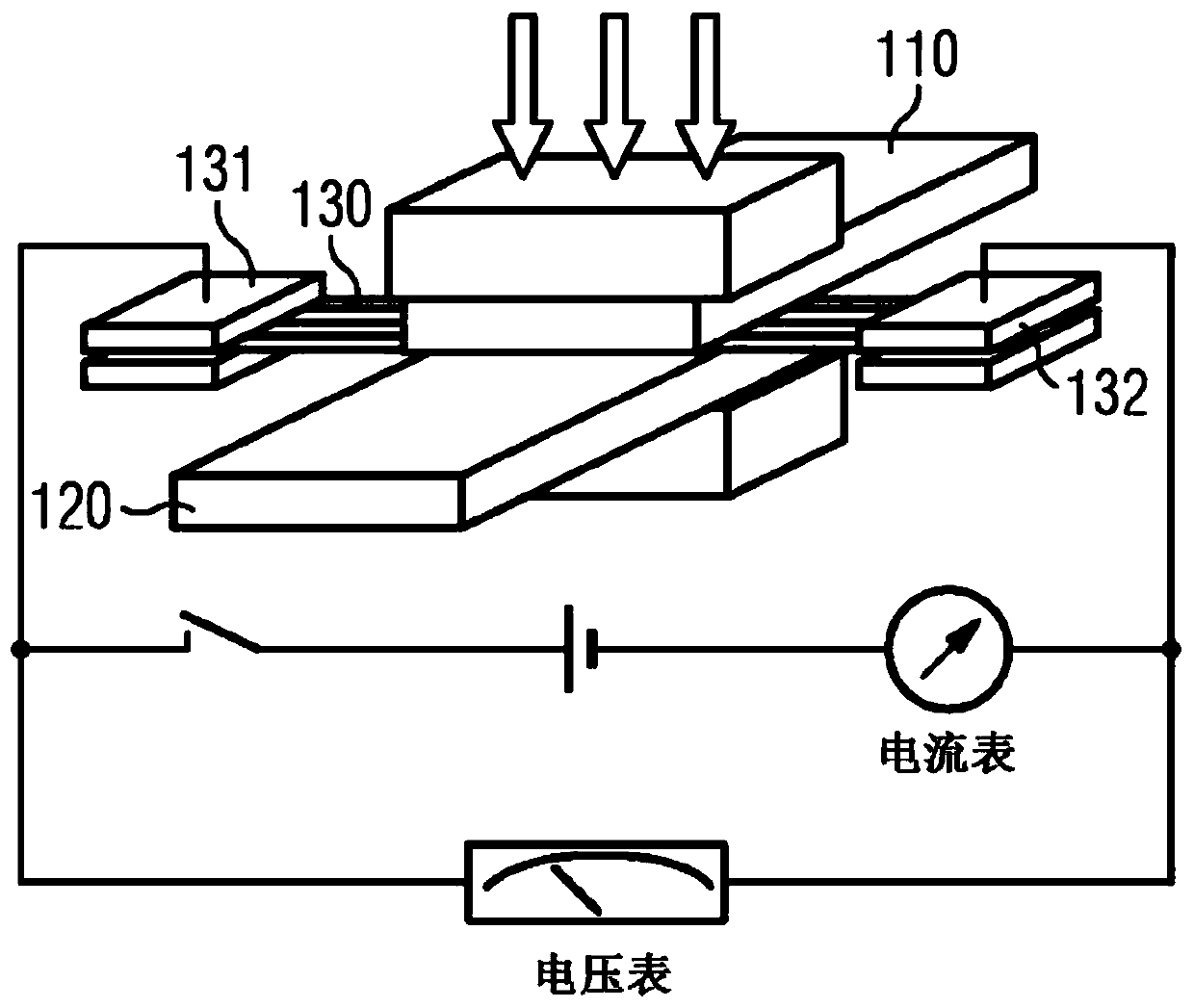

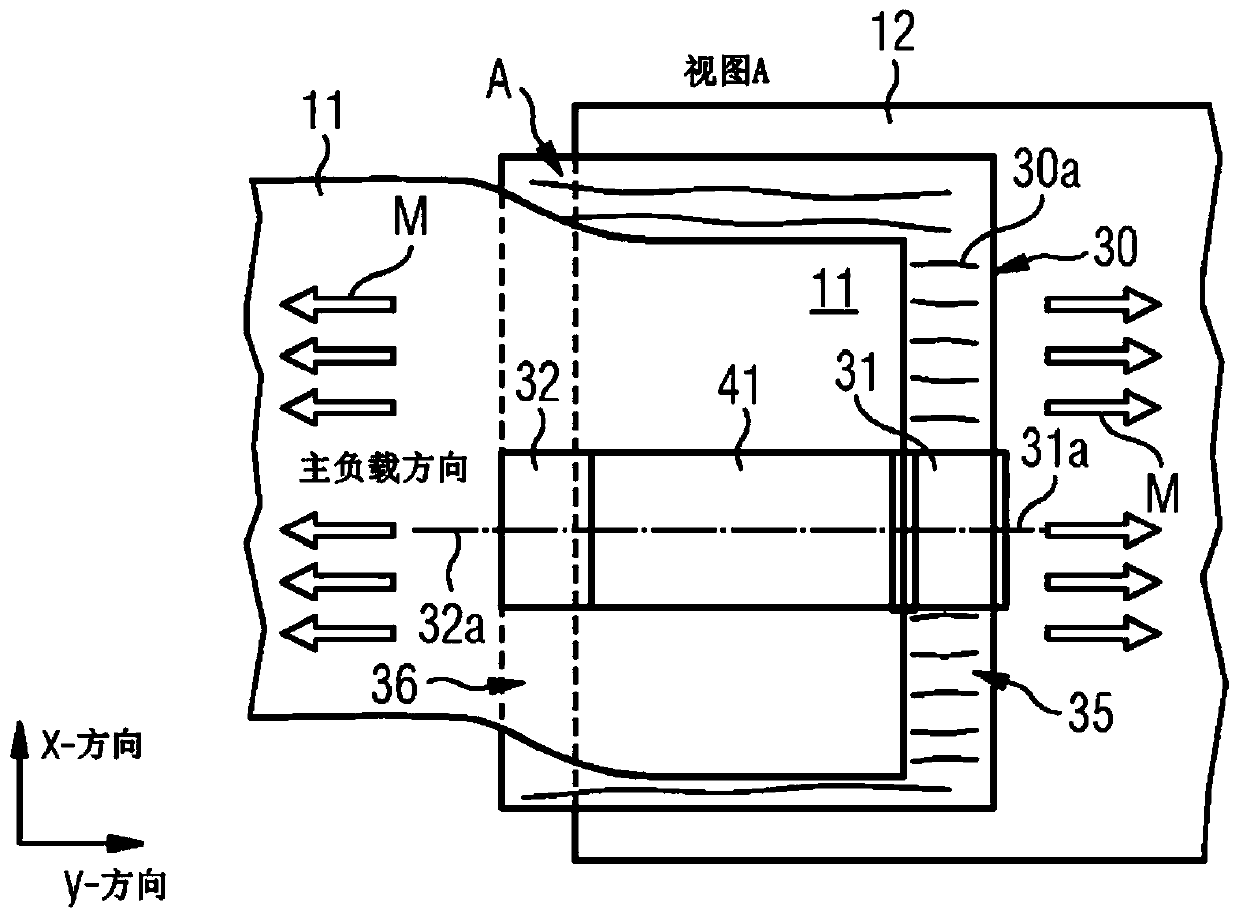

[0069] figure 1 A cross-sectional view of a system or device for joining thermoplastic parts of an aircraft by means of resistance welding is shown in accordance with a preferred embodiment of the present invention. The device or resistance welding system comprises an electrically conductive heating element 30 for welding the first part 11 to the second part 12 in the electrically heated area of the parts.

[0070] The parts 11 , 12 to be welded comprise thermoplastic material and are arranged in overlapping regions on both sides of the heating element 30 for resistance welding.

[0071] The heating element 30 comprises an electrically conductive element 30a formed as a wire and / or fiber for heating the components 11, 12 when an electrical voltage is applied (see also Figure 3a and 3b ). The heating element 30 is designed to remain in the welded joint after the welding process and to be permanently used as a reinforcing element therein for the parts 11 , 12 welded to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com