Muddy water and air balance shield pressure control method and device

A pressure control, mud-water-gas technology, which is applied in the air pressure adjustment to realize the balance of shield excavation surface. Through the mud-water field, problems such as imbalance and difficult control of surface subsidence can be solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

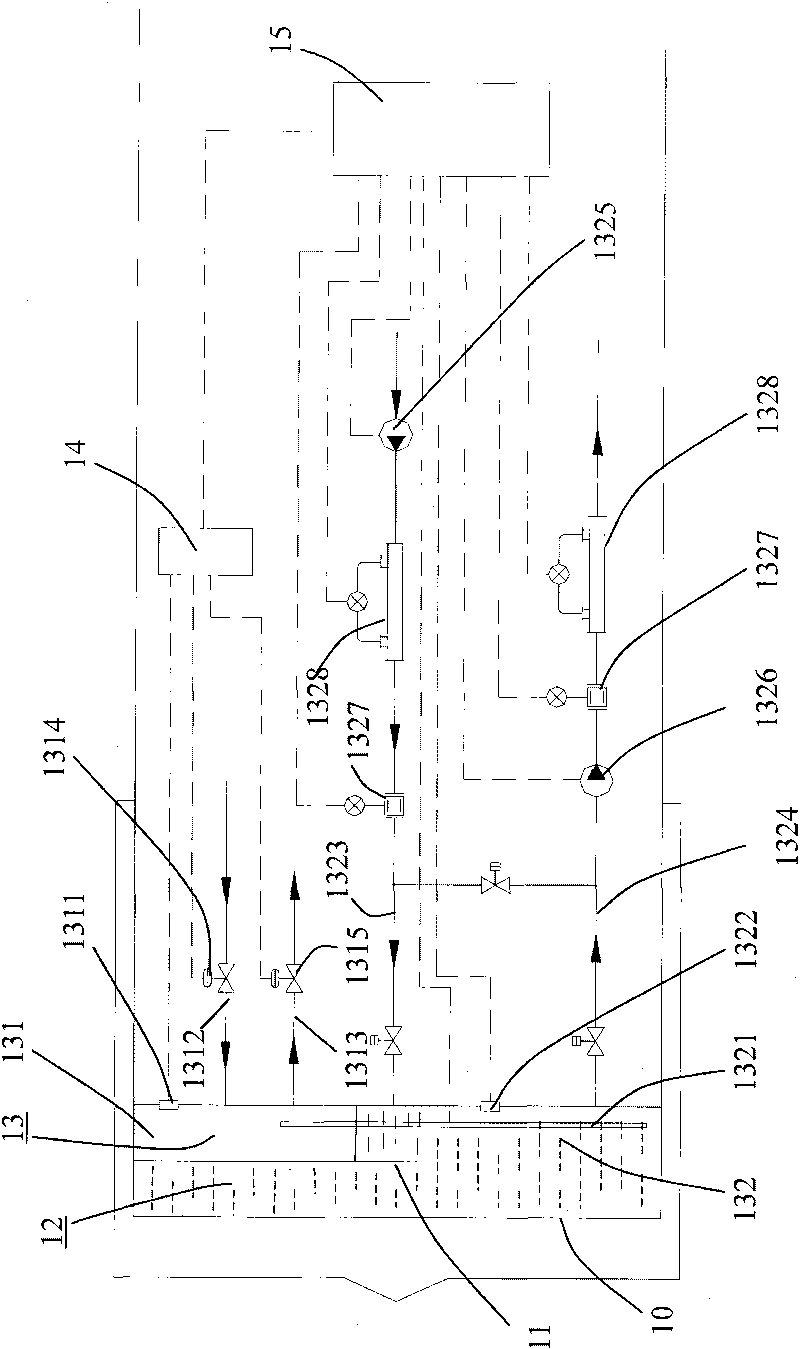

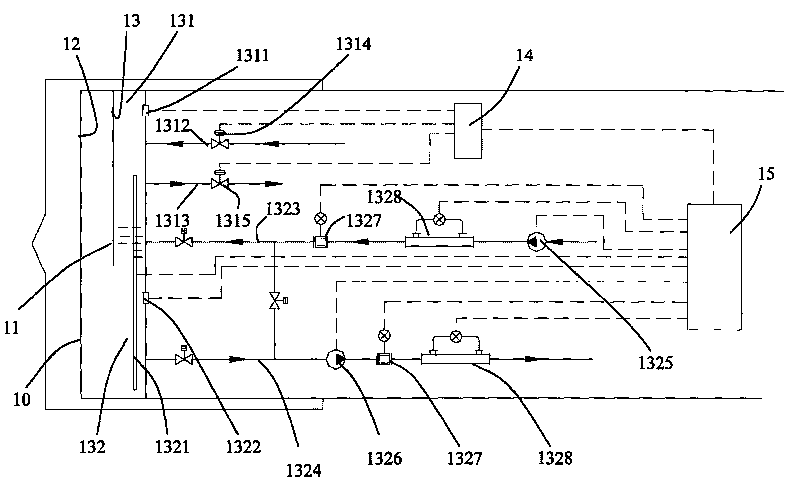

[0012] refer to figure 1 As shown, the pipeline connection diagram of the muddy water gas pressure regulating system of the present invention is shown. Wherein, a half partition 11 is vertically arranged in the shield muddy water bin 10, and the half partition 11 divides the shield muddy water bin 10 into a front muddy water bin 12 close to the side of the cutter head and a rear muddy water bin relatively far away from the cutter head. 13 two parts; the upper part of the front muddy water bin 12 and the rear muddy water bin 13 is separated by a half partition 11, and the lower parts of the two communicate with each other; the muddy water in the front muddy water bin 12 is completely filled, and the upper part of the rear muddy water bin 13 is injected Compressed air, its bottom is still full of muddy water, has thus formed air chamber 131 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com