Vacuum composite heat-insulating pipeline connecting structure

A technology for connecting structures and heat-insulating pipes, which is applied in the direction of drilling pipes, casings, and drilling equipment. It can solve problems such as poor heat insulation performance, high specific gravity, and easy aging of heat-insulating bushings, and achieve simplified quantity and assembly. process, prolong the life of heat insulation, and improve the effect of heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

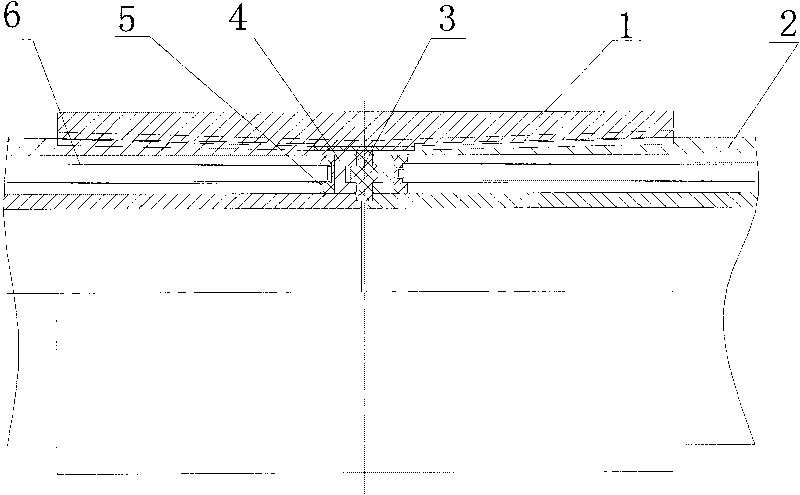

[0011] This embodiment is composed of a vacuum composite heat insulation pipe 2, a coupling 1 and a sealing gasket 3. The coupling 1 is a metal pipe. Both ends of the inner hole of the coupling are taper holes with a large outer diameter and a smaller inner diameter. The connection part of the two vacuum composite heat insulation pipes 2 is connected, and the outer surface of the connection part of the vacuum composite heat insulation pipe is a threaded conical surface that matches with the threaded conical hole at either end of the inner hole of the coupling, and the end of the vacuum composite heat insulation pipe 2 is welded There is a sealing plug 4, and one or more rings of grooves are arranged on the outer end surface of the sealing plug 4, and one ring of grooves is arranged in this embodiment.

[0012] The vacuum composite heat insulation pipe 2 is composed of an inner pipe and an outer pipe. A double-layer evacuated pipe 6 is arranged between the inner and outer pipes. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com