Biological cell wall breaking system and biological effective component extracting system based on laser plasma technology

A technology of laser plasma and biological cells, applied in the field of biological active ingredient extraction system, can solve the problem of low extraction rate and achieve the effect of high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

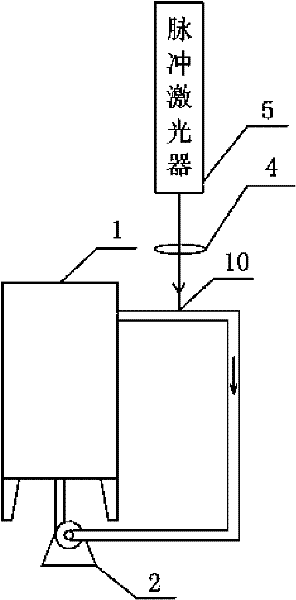

[0009] Specific implementation mode one: combine figure 1 and image 3 Describe the present embodiment, the biological cell wall breaking system based on laser plasma technology of the present embodiment, it comprises liquid storage tank 1, feeding pump 2, focusing lens 4, pulse laser 5 and feed tube 10, liquid storage tank 1 The discharge port of the feed pipe 10 is connected to the feed port of the feeding pump 2, and the discharge port of the feed pump 2 is connected to the feed port of the liquid storage tank 1. There is a laser injection port on the surface of the feed pipe 10, and the pulse laser The optical signal output from the laser output end of 5 is input to the laser inlet of the material guide tube 10 after passing through the focusing lens 4 .

[0010] In this specific embodiment, the biological material to be treated is composed of plant body, animal body or microbial material, and the pulverized material and solvent are placed in the liquid storage tank 1. Af...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination Figure 4 To describe this embodiment, the difference from Embodiment 1 is that this embodiment further includes an ion cover 3 , and the ion cover 3 is placed in the laser injection port of the material guide tube 10 and connected to the material guide tube 10 .

[0012] In this specific embodiment, the laser output from the pulsed laser 5 is focused on the ion shield 3 through the focusing lens 4, so that the ion shield 3 is ionized to generate high-temperature and high-density plasma. The material of the ion shield 3 can be selected from non-toxic metal materials such as Fe and Al.

specific Embodiment approach 3

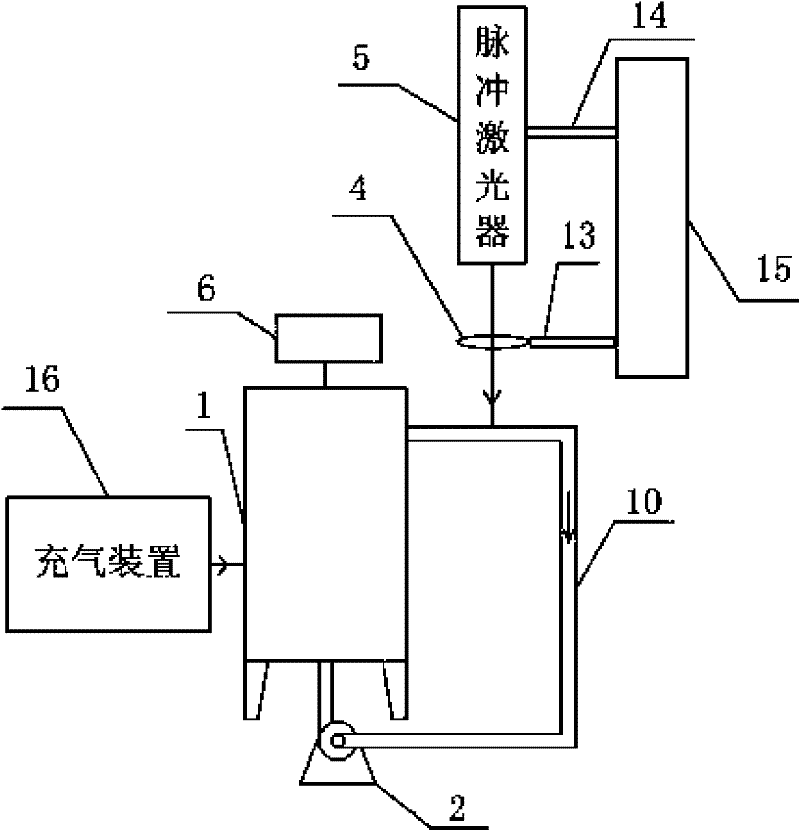

[0013] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the difference from Embodiment 1 or Embodiment 2 is that this embodiment further includes a stirrer 6 , and the stirring blades of the stirrer 6 are placed in the liquid storage tank 1 .

[0014] The stirrer 6 is used for stirring the material in the liquid storage tank 1 to make it mix evenly.

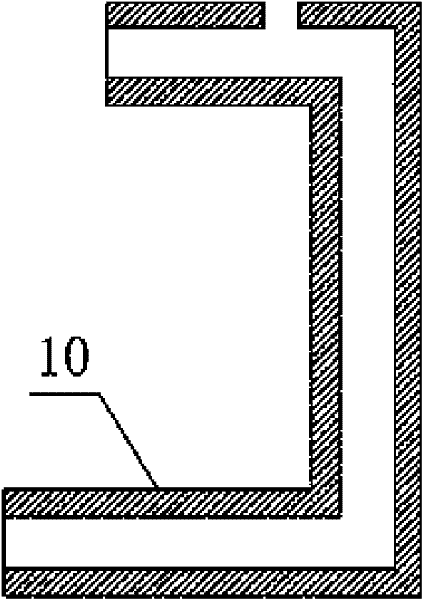

[0015] Specific implementation mode four: combination figure 2 and Figure 5 Illustrate this embodiment, different from embodiment one, two or three, the material guide tube 10 of this embodiment is made up of front end material guide tube 11 and rear end material guide tube 12 with different inner diameters, the inner diameter of front end material guide tube 11 Smaller than the inner diameter of the rear end feed pipe 12, the outlet of the liquid storage tank 1 is connected to the input end of the front end feed pipe 11, the output end of the front end feed pipe 11 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com