Biodegradable metal drawing lubricating oil and method for producing same

A technology of metal wire drawing and biodegradation, applied in the direction of lubricating compositions, petroleum industry, base materials, etc., can solve the problems of non-renewable mineral oil and cannot be directly discharged, achieve excellent emulsification effect, reduce surface quality defects, and reduce wire drawing energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

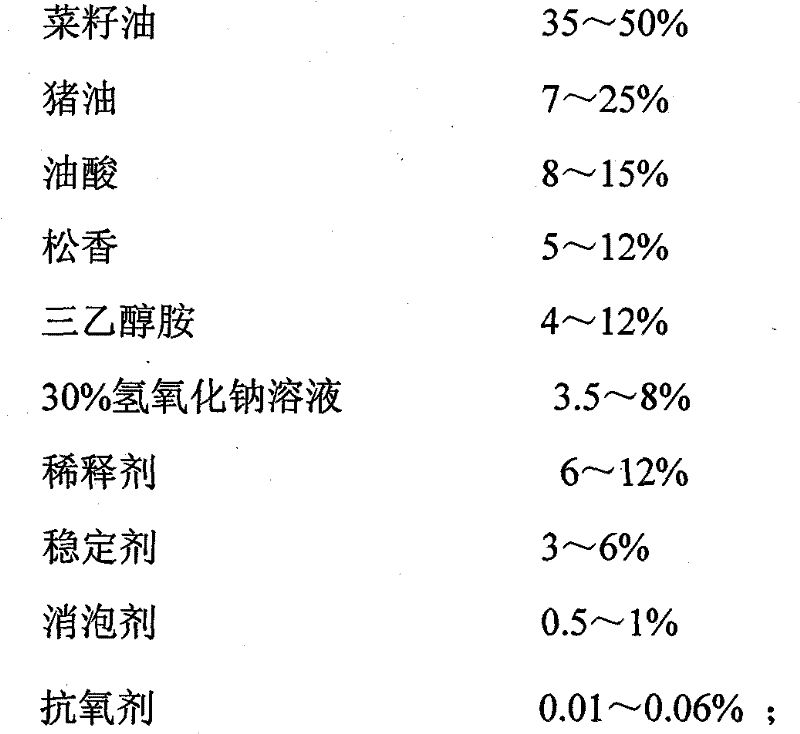

[0039] Example 1. ① Take 10g rosin, 2.2g oleic acid, 50g vegetable oil and 10g lard, stir and heat to 120°C, slowly add 30% sodium hydroxide dropwise to dissolve 7g, fully react and set aside; ②Take 12g triethanolamine and 21g Dehydrated ethanol, heated to 60°C, slowly added 20g of oleic acid, stirred for 20 minutes, added 32g of rapeseed oil and 16g of lard, stirred for 20 minutes for later use; ③mixed the liquid system obtained in steps ① and ②, stirred at 60°C After 20 minutes, cool to room temperature; ④Add 1.2g methyl silicone oil, 0.03g 2,6-di-tert-butyl-p-cresol, 7g absolute ethanol to the oil sample obtained in step ③, and stir until there is no precipitation to obtain the product .

example 2

[0040] Example 2. ①Take 6.8g rosin, 2g oleic acid, 20g vegetable oil and 11g lard, stir and heat to 110°C, slowly add 30% sodium hydroxide dropwise to dissolve 4g, fully react and set aside; ②Take 6g triethanolamine and 7gPE6400 , heated to 70°C, slowly added 10g of oleic acid, stirred for 20min, added 16g of rapeseed oil and 4g of lard, stirred for 20min and set aside; ③mixed the liquid system obtained in steps ① and ②, and stirred at 60°C for 20min, Cool to room temperature; ④Add 0.6g of methyl silicone oil, 0.01g of 2,6-di-tert-butyl-p-cresol, 4g of absolute ethanol to the oil sample obtained in step ③, and stir until there is no precipitation to obtain the product.

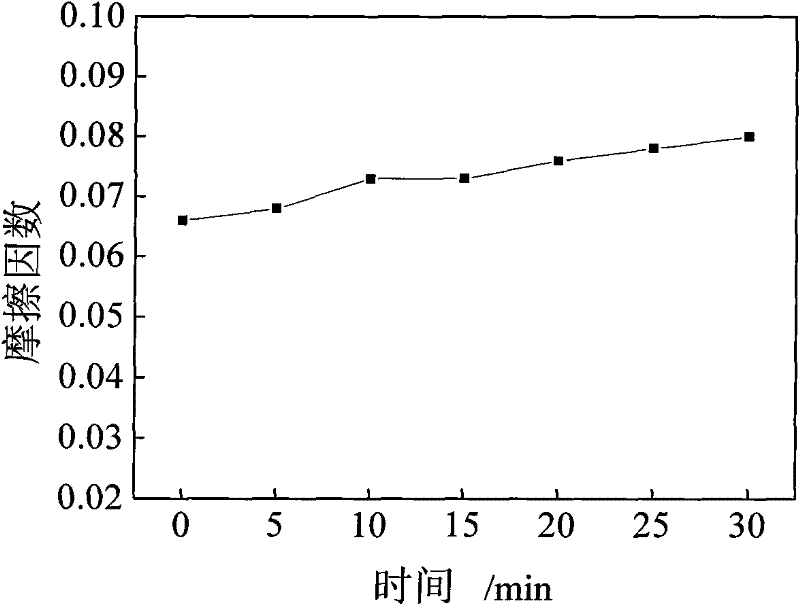

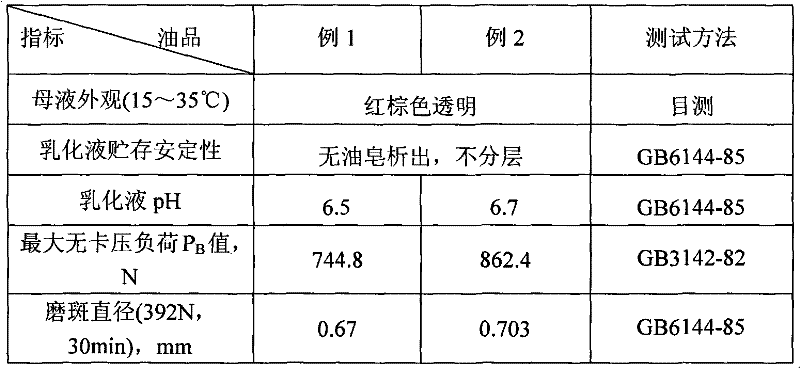

[0041] Each oil product in the embodiment is formulated into a 5% emulsion according to GB3142-82, and its oil film strength is measured on an MQ-800 type four-ball testing machine, and the results are shown in Table 1. It can be seen from Table 1 that the emulsion has certain extreme pressure and antiwear pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com