Face-type structural 3(8-hydroxyquinoline) aluminium nano and micro materials and preparation method thereof

A hydroxyquinoline, nano-micron technology, applied in the direction of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

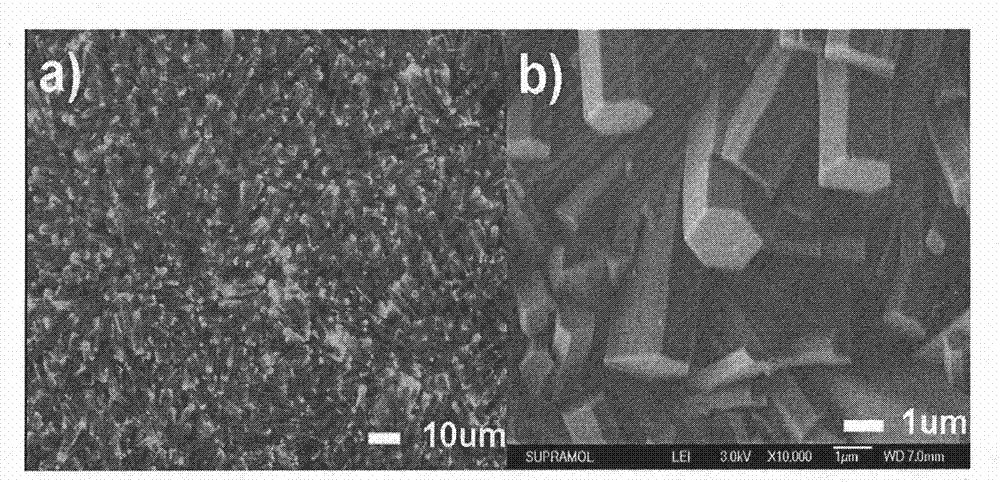

[0021] Example 1: Preparation of surface Alq 3 Nano-micron film

[0022] 1: Utilize Alq 3 Prepare Alq as raw material 3 Amorphous film

[0023] Alq 3 The solid raw material is purified by a conventional vacuum sublimation method, and then deposited at room temperature to prepare an amorphous film. This purification method can prepare pure meridian Alq 3 powder. Using quartz glass as the substrate, using a vacuum evaporation apparatus (the vacuum degree is about 10 -5 ~10 -6 Torr) heating and evaporating the above formula Alq at a temperature of 230℃(±10℃) 3 Powder to prepare Alq with a thickness of 50~2000nm on the substrate by vacuum deposition method 3 Amorphous film.

[0024] 2: Surface Alq 3 Nano and micron film preparation

[0025] Two pieces are plated with Alq 3 The quartz glass substrate of the amorphous film is placed face-to-face in a glass container, and the bottom of the container has a certain amount (100~500mg) of meridian Alq 3 For solid powder, vacuumize the glass cont...

Embodiment 2

[0026] Example 2: Using surface Alq 3 Single carrier transport device with nano-micro structure film as active layer

[0027] 1: Make Alq 3 The amorphous film method is as described in Example 1;

[0028] 2: Preparation of surface Alq 3 The nano-micron film is as described in Example 1;

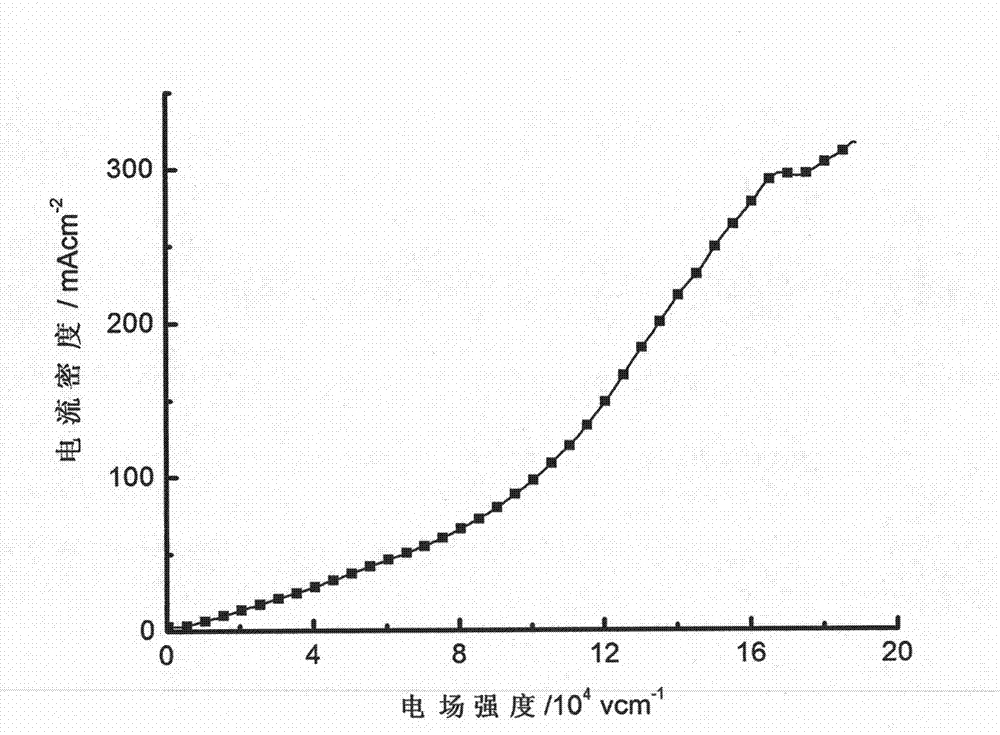

[0029] 3: Preparation based on surface Alq 3 Single-carrier transport device with nano-micro structure ultra-thin film

[0030] The device structure is: [ITO / surface Alq 3 (1000nm) / LiF(15nm) / Au(2000nm)]. Preparation of surface Alq on ITO surface 3 Nano-micron film, ITO as anode, LiF and Au as composite cathode. Conductivity test proves surface Alq 3 Nano-micro films have good hole injection and transport properties. The specific experimental data of device performance are as follows figure 2 Shown. As the voltage increases, the current of the device gradually increases, when the electric field strength reaches 16×10 4 When volts / cm, the current density reaches 300mA / cm2, indicating that the surfac...

Embodiment 3

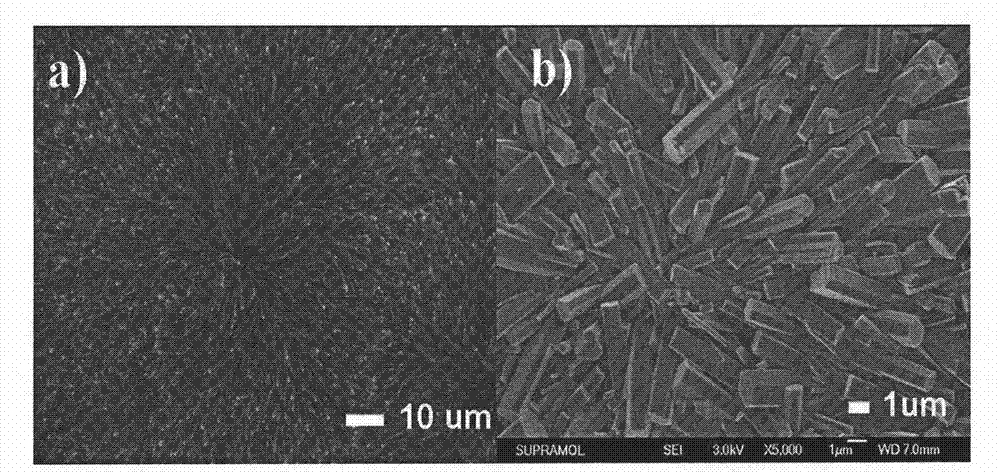

[0031] Example 3: Preparation of meridian Alq by double substrate method 3 Nano-micron film

[0032] 1: Utilize Alq 3 Prepare Alq as raw material 3 Amorphous film

[0033] Alq 3 The solid raw materials are purified by a conventional vacuum sublimation method. The samples deposited at room temperature are used to prepare amorphous films. This purification method can prepare pure meridian Alq 3 powder. Using quartz glass as the substrate, using a vacuum evaporation apparatus (vacuum degree of 10 -5 ~10 -6 Torr) heating and evaporating Alq at 230℃(±10℃) 3 , Prepare Alq with a thickness of 50~2000nm by vacuum deposition method 3 Amorphous film.

[0034] 2: Classical Alq 3 Preparation of nano and micro materials

[0035] Two pieces are plated with Alq 3 The quartz glass substrate of the amorphous film is placed face-to-face in a glass container, and the bottom of the container has a certain amount (100~500mg) of meridian Alq 3 For solid powder, vacuumize the glass container to remove oxyge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com