Roller type tension station applicable to rolling multiple rollers

A roller type, tension technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of uneven winding of narrow belts, asynchronous rotation speed, etc., and achieve neat winding, use cost and maintenance cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

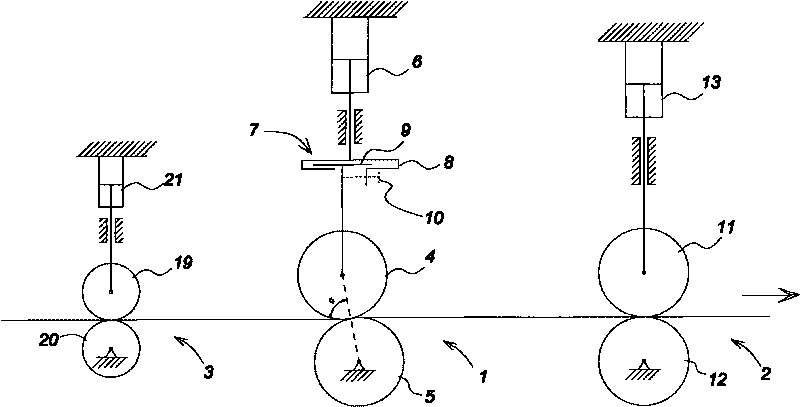

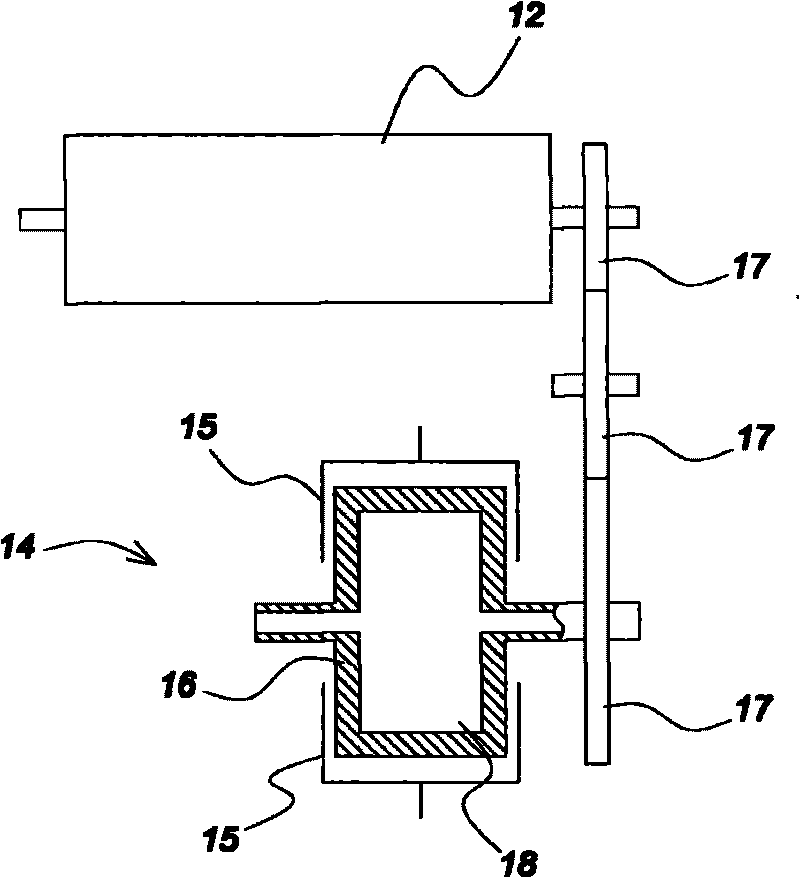

[0021] After the steel and aluminum strips cut by the slitting machine enter the tension station of this embodiment, they will be wound up by the winder. The tension station in this embodiment is provided with a first roller set 1 , a second roller set 2 and a regulating roller set 3 .

[0022] Such as figure 1 As shown, the first roller group 1 is composed of the first pressure roller 4 and the first resistance roller 5. The first pressure roller 4 can apply downward pressure under the action of the first hydraulic piston cylinder 6. In order to obtain better leveling As a result, the angle α between the line connecting the axis between the first pressure roller 4 and the first resistance roller 5 and the advancing direction of the steel-aluminum strip is 80°. The appearance of the angle α is caused by the fine-tuning mechanism 7. The fine-tuning mechanism 7 is composed of a sliding seat 8 and a sliding block 9 matched with the sliding seat 8. The sliding seat 8 is fixed on ...

Embodiment 2

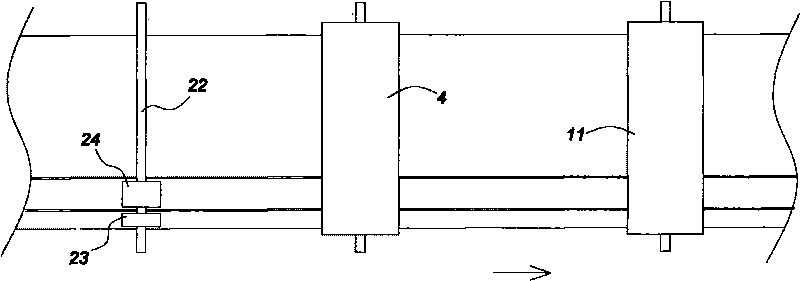

[0028] The difference between this embodiment and embodiment 1 is: as Figure 4 As shown, only one rubber roller section 26 is installed on the adjustment roller shaft 22', and the rubber roller section 26 corresponds to three narrow strips of equal width as the target steel and aluminum strips, and provides additional leveling resistance and Tensile resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com