Production technology of grape pip and grape skin extract

A production process, grape seed technology, applied in the field of grape seed and skin extract production process, can solve the problems of low quality, low quality and value, low content, etc., to increase content, improve product quality and value, and effectively The effect of increasing the content of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

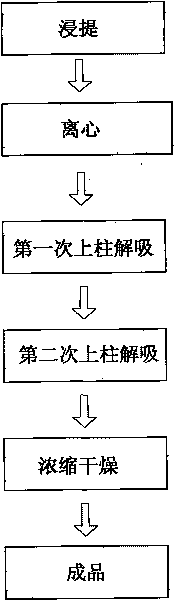

[0021] combine figure 1 Shown, the production technology of grape seed of the present invention, skin extract, comprises the following steps:

[0022] 1. Extract active ingredients from grape seeds and skins

[0023] 1.1. Extraction: Add 8 times of 50-70% ethanol to the collected grape seeds and skins, and extract the grape seeds and skins for 3 times, the first time is 3 hours, the second time is 2.5 hours, and the third time is 2 hours. hour, the extraction temperature was 70 degrees, and then the extract was collected.

[0024] 1.2. Ethanol recovery: Evaporate the extract in vacuum, recover ethanol, add water to the extract and cool it for later use.

[0025] 1.3. Centrifugation: The extract was subjected to three-stage centrifugation at 1000 rpm, 4400 rpm, and 14000 rpm, respectively, and the supernatant was collected after centrifugation. Among them, the first stage of centrifugation is mainly to remove large particles of impurities in the extract, the second stage of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com