Frequency-modulation electronic ballast for dimmable fluorescent lamp

A technology of electronic ballasts and fluorescent lamps, which is applied in the direction of high-efficiency power electronic conversion, light sources, electric light sources, etc., can solve the problems of EMI radiation, affecting circuit and power factors, and inability to guarantee power switching tubes when adding electronic ballasts, etc., to achieve The effect of simple overall structure and high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

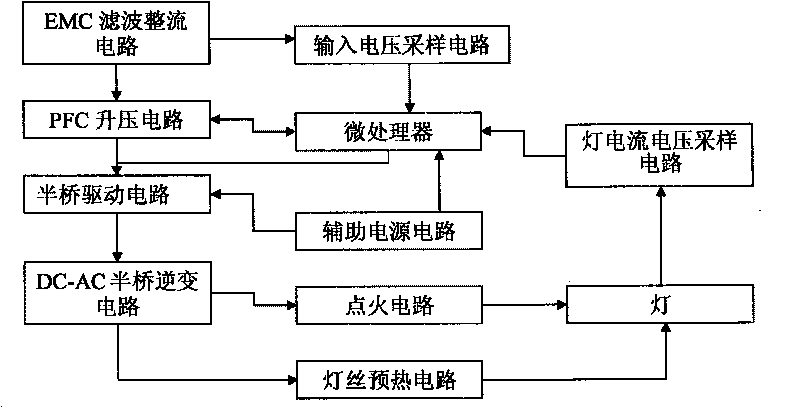

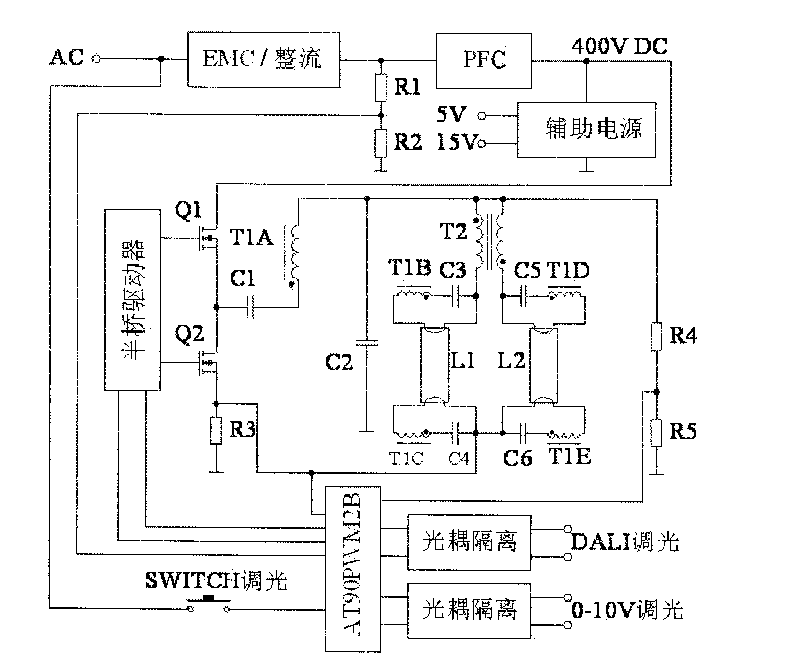

[0018] like figure 1 , 2 As shown, the electronic ballast for frequency-modulated dimmable fluorescent lamps of the present invention includes an EMC filter rectifier circuit, an input voltage sampling circuit, a PFC boost circuit, a half-bridge drive circuit, a DC-AC half-bridge inverter circuit, a micro Processor, lamp current lamp voltage sampling circuit. The EMC filter rectifier circuit is connected to the PFC boost circuit, the half-bridge drive circuit is connected to the DC-AC half-bridge inverter circuit, the lamp current lamp voltage sampling circuit is connected to the microprocessor, and the input voltage sampling circuit is connected to the microprocessor . The electronic ballast for frequency-modulated dimmable fluorescent lamps of the present invention also includes an auxiliary power supply circuit, and both the microprocessor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com