Device for recycling gas purified from spray paint waste gas in spray room

A technology of exhaust gas purification and air circulation, which is applied in the direction of combined devices, chemical instruments and methods, and the separation of dispersed particles, etc., can solve the problems of zero emission of exhaust gas that has not yet been discovered, and the effect of spraying exhaust gas is not much.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

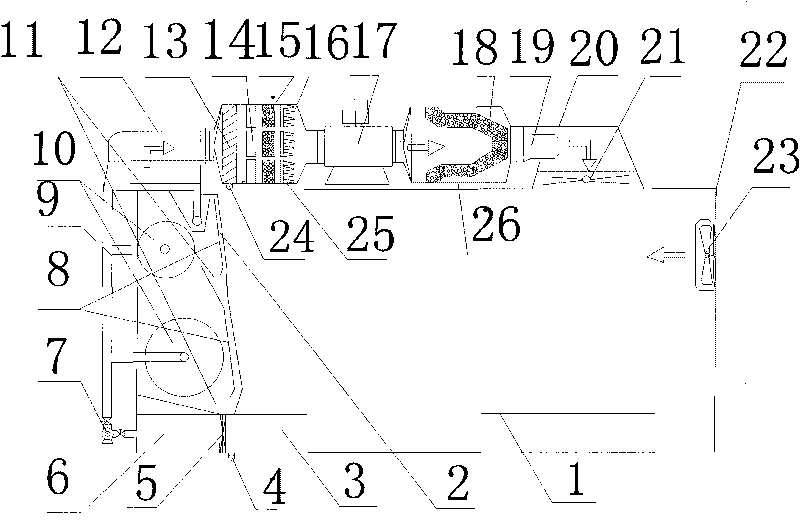

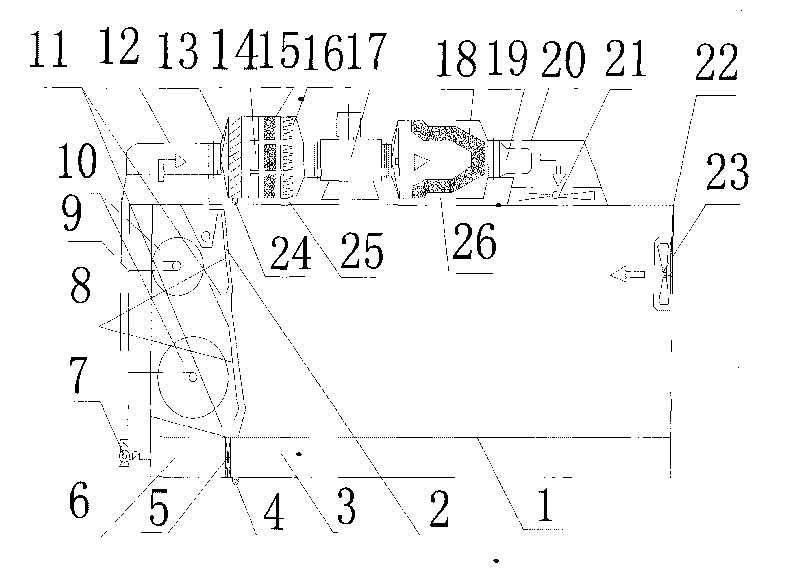

[0015] In order to fully explain the "paint spray booth exhaust gas purification and circulation device", the following instructions are made:

[0016] 1. Manufacture and assembly:

[0017] ①, according to figure 1 , Requirements, do a good job in the manufacture and assembly of the "painting exhaust gas purification and circulation device in the spray booth".

[0018] ②, in (25) "secondary treatment tank", put (13) "louver baffle plate", (14) "coarse effect paint blocking cotton", (15) "activated carbon filter cotton" (16) F7 medium effect Filter; (18) "almond shell activated carbon" is packed into (26) "three-stage purification tank", and (19) "dust bag" is packed into (20) "clean air duct";

[0019] ③. Carry out trial run after assembly.

[0020] 2. Production preparation:

[0021] ①. Inject an appropriate amount of water into (3) the waste water pool;

[0022] ②, turn on (7) water supply pump, let the water flow out through (9) water pipe and spray (overflow) water ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com