Hollow cathode electric arc ion coating plating system

A cathodic arc and coating system technology, applied in the direction of ion implantation plating, coating, vacuum evaporation plating, etc., can solve the problem that can not meet the requirements of thick coatings, can not meet the requirements of wear and corrosion resistance, filter technology deposition rate It can improve the coating efficiency and ion plating effect, be easy to control, and improve the coating deposition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

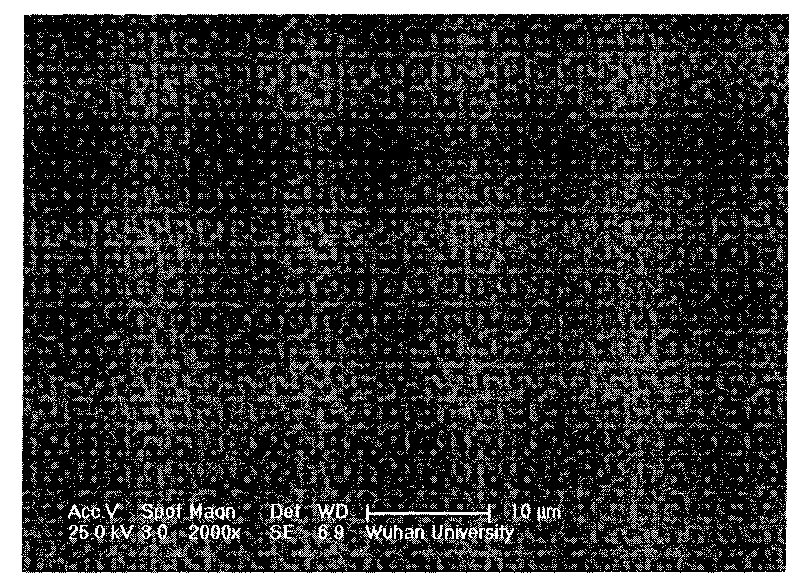

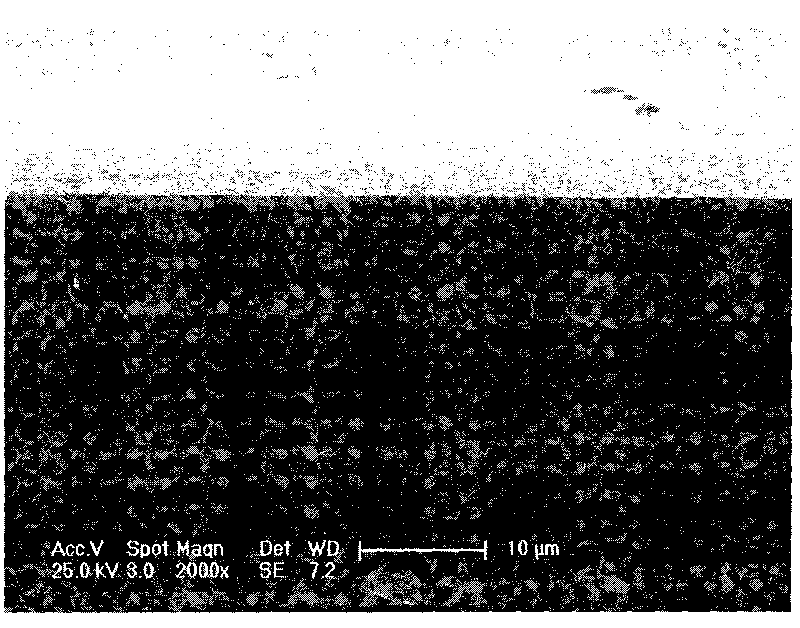

[0029] Embodiment 1: under the condition of 0.02Pa, negative 200V bias, utilize the metal Ti arc target controlled by electromagnetic field to prepare pure Ti metal transition layer; the deposition thickness of metal transition layer is 100-200 nanometers; Pass into nitrogen then, air pressure maintains 1Pa , Open the arc target on the furnace wall, and use nitrogen to react with Ti sputtered from the target surface to form TiN. The preparation temperature is 400-450°C, and the bias voltage is negative 200V. The thickness of TiN coating is 20-30 microns. The flow rate of nitrogen gas is 50-200 sccm; the current of the hollow cathode arc target is 300A.

[0030] The control of the above-mentioned hollow cathode arc target control surface arc target is produced by an electromagnetic coil placed behind the arc target. A uniformly distributed magnetic field with a strength of 50-60 Gauss is generated on the target surface.

Embodiment 2

[0031] Embodiment 2: Under the condition of 0.05Pa, negative 150V bias, the metal Cr arc target controlled by electromagnetic field is used to prepare pure Cr metal transition layer; the deposition thickness of metal transition layer is 200-300 nanometers; then pass into nitrogen, and the air pressure is maintained at 2.3 Pa, open the arc target on the furnace wall, and use nitrogen to react with Cr sputtered from the target surface to form CrN. The preparation temperature is 400-450°C, and the bias voltage is negative 150V. The thickness of CrN coating is 20-30 microns. The flow rate of nitrogen gas is 180-250 sccm; the current of the hollow cathode arc target is 350A.

[0032] The control of the above-mentioned hollow cathode arc target control surface arc target is produced by an electromagnetic coil placed behind the arc target. A uniformly distributed magnetic field with a strength of 60-70 Gauss is generated on the target surface.

Embodiment 3

[0033] Embodiment 3: Under the condition of 0.04Pa, negative 250V bias, utilize the metal Zr electric arc target of electromagnetic field control to prepare pure Zr metal transition layer; The deposition thickness of metal transition layer is 300-400 nanometer; Pass into nitrogen then, air pressure keeps 3.3 Pa, open the arc target on the furnace wall, and use nitrogen to react with Zr sputtered from the target surface to generate ZrN. The preparation temperature is 350-450°C, and the bias voltage is negative 250V. The thickness of the ZrN coating is 25-50 microns. The flow rate of nitrogen gas is 250-300 sccm; the current of the hollow cathode arc target is 400A.

[0034] The control of the above-mentioned hollow cathode arc target control surface arc target is produced by an electromagnetic coil placed behind the arc target. A uniformly distributed magnetic field with a strength of 70-80 Gauss is generated on the target surface.

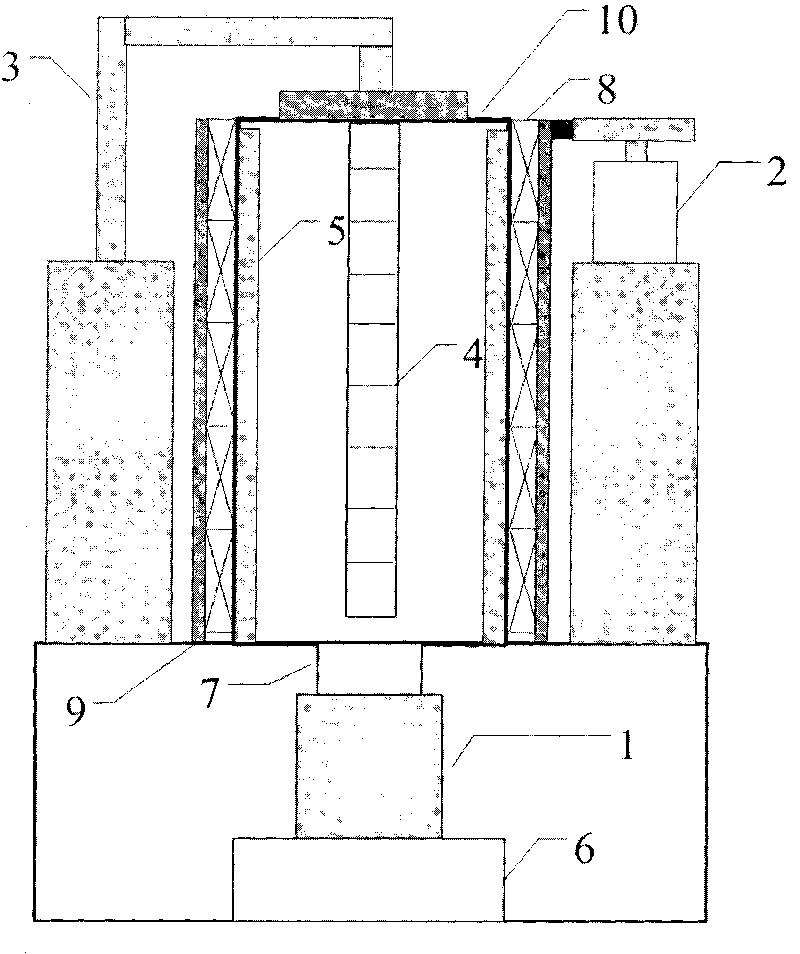

[0035] figure 1 It is a self-made high-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com