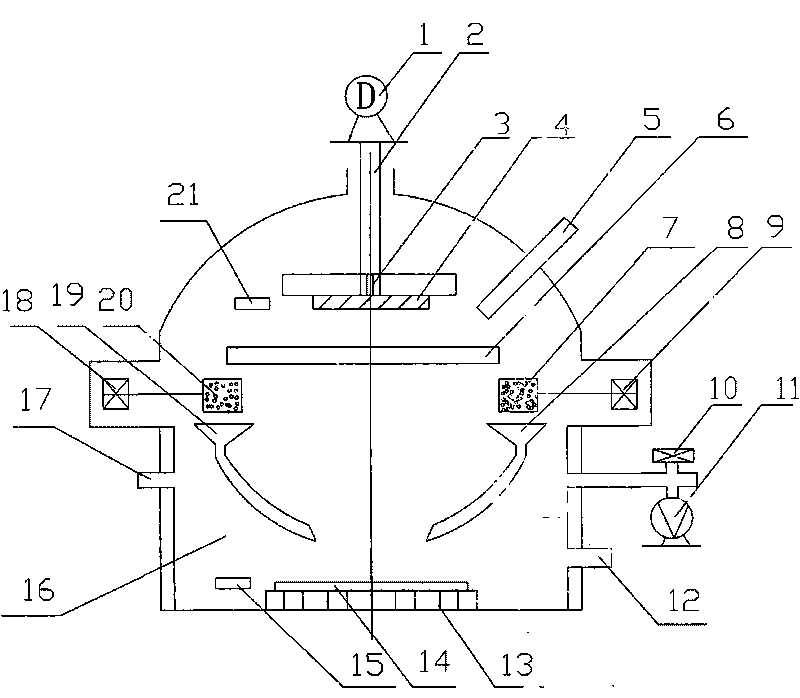

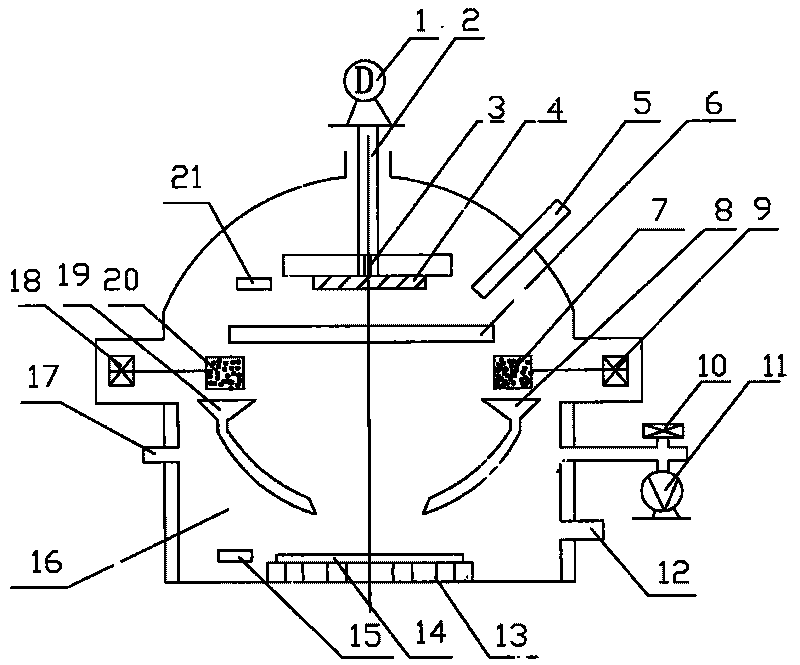

Double-flash evaporation device for preparing superlattice thermoelectric film material

A technology of thermoelectric thin film and flash evaporation method, which is applied in metal material coating process, vacuum evaporation plating, ion implantation plating, etc., can solve the problems of high cost, complicated preparation process, and difficulty of superlattice thermoelectric thin film materials, etc. Achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation of superlattice thermoelectric thin film materials: The first is the synthesis of raw materials, using elemental Bi (99.9%, 200 mesh), Te (99.99%, 200 mesh), Sb (99.99%, 100 mesh) and Se (99.9%, 100 mesh). Mesh) The powder is used as the raw material. The experiment uses a planetary gear ball mill for mechanical alloying of the powder. The ball mill tank and the grinding ball are made of stainless steel. P-type and N-type thermoelectric materials are in accordance with Bi 0.5 Sb 1.5 Te 3 And Bi 2 Te 2.7 Se 0.3 The compound ingredients are mixed, and then the so-called powder is loaded into a ball mill tank for mechanical alloying. In order to prevent oxidation, the powder filling and powder taking are carried out in a glove box filled with argon gas. The ball milling atmosphere is high-purity argon gas. The ball milling process is: the ball-to-material ratio is 15:1, the ball milling speed is 400r / min, and the ball milling time is 10h. Subsequently, the m...

preparation example

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com