Inspection robot wheel-claw compound mechanism

An inspection robot and wheel claw technology, applied in the field of robotics, can solve the problems of difficulty in robot offline, poor safety protection, complex walking structure, etc., and achieve the effects of light weight, high clamping efficiency and compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further detail below through the embodiments and accompanying drawings.

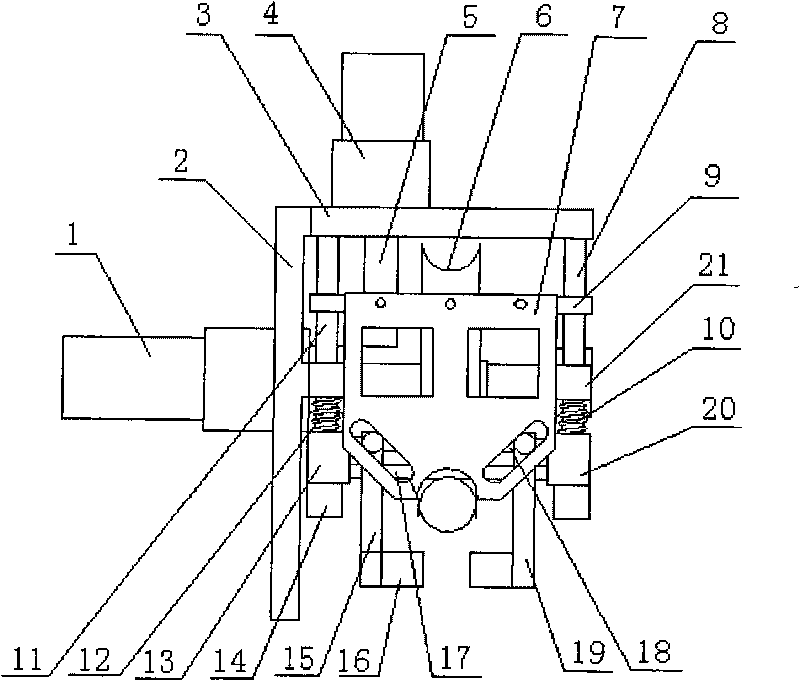

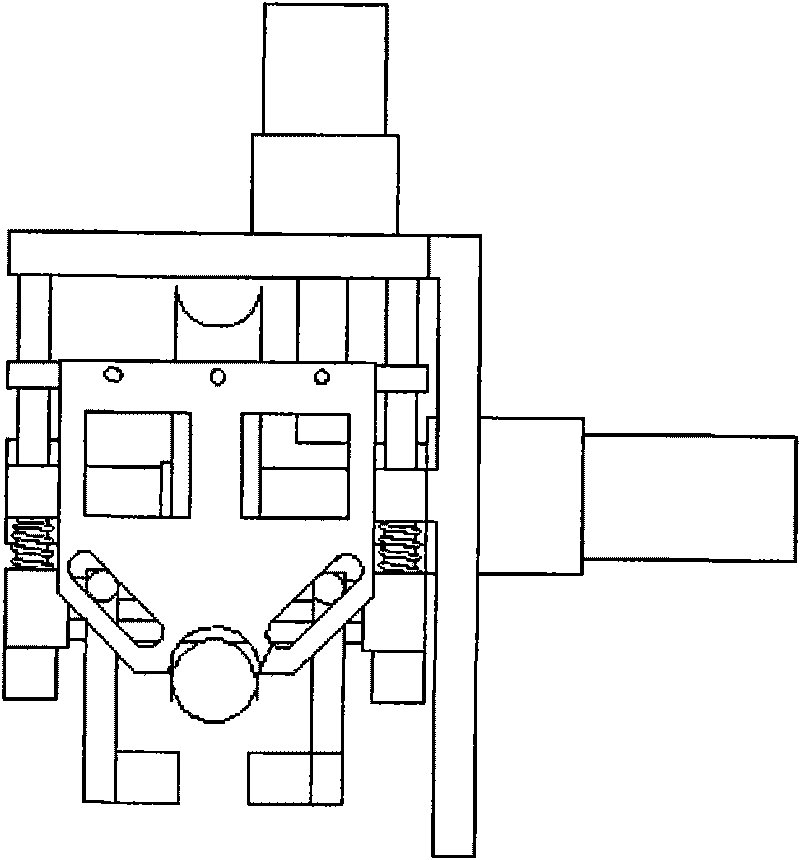

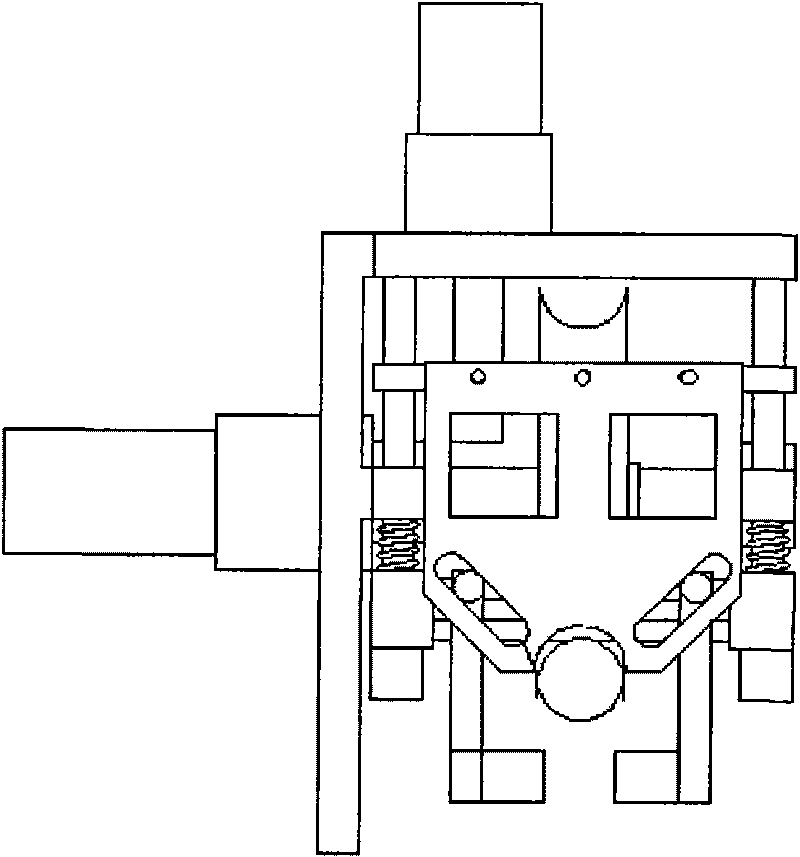

[0024] figure 1 It is a structural schematic diagram of the wheel claw compound mechanism of the inspection robot of the present invention; figure 2 is the back view of the figure; image 3 It is a schematic diagram of the released state of the embodiment of the present invention; Figure 4 It is a schematic diagram of the closed state of the embodiment of the present invention; Figure 5 It is a schematic diagram of the clamping state of the embodiment of the present invention; Figure 6 It is the left view of the wheel and claw compound mechanism of the inspection robot of the present invention.

[0025] The illustration is introduced with the structure of four vertical polished rods and two horizontally moving lead screws at the front and rear respectively, but the present invention is not limited thereto, and equivalent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com