Improved connecting rod drive mechanism of butterfly valve plate

A technology of connecting rod drive and butterfly valve plate, applied in the direction of valve housing structure, engine components, lift valve, etc., can solve the problems of high power input requirements of supporting power source, structural deformation limitation, and difficulty in guaranteeing the reverse sealing effect of the sealing pair, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

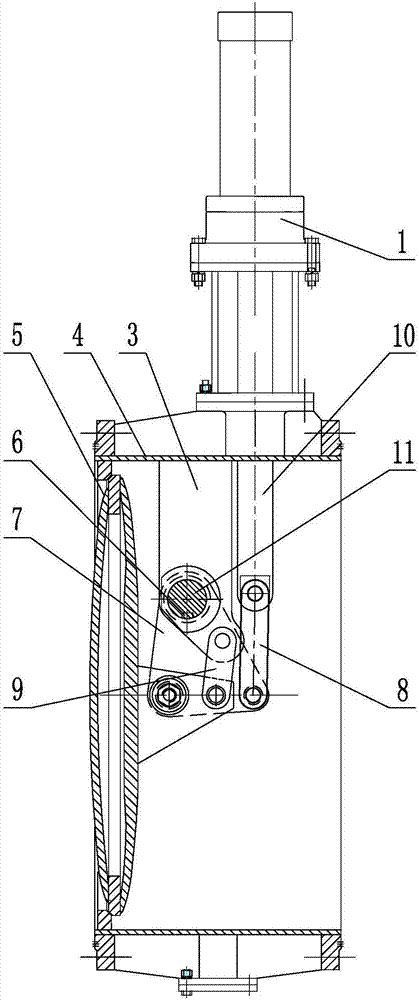

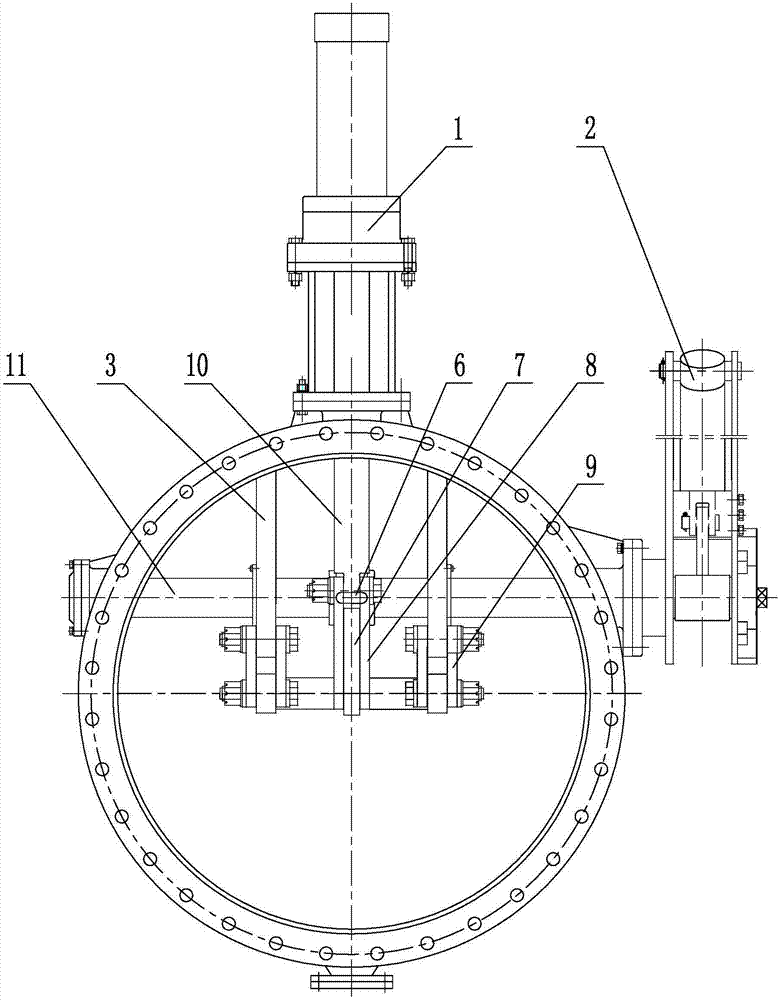

[0081] The improved connecting rod drive mechanism of the butterfly valve plate includes a valve body 4, a valve plate 5, a push-pull drive shaft 10 located in the valve body 4 and driven longitudinally by the parallel push-pull mechanism 1, the valve plate 5 is located in the valve body 4, and the triangular plate 7 It is perpendicular to the valve plate 5 and the main shaft 11 and its top is matched with the main shaft 11. The lower inner end of the triangular plate 7 is hinged with the fixed seat on the valve plate 5, and the lower outer end of the triangular plate 7 is movably assembled with the lower end of the push-pull drive shaft 10. The valve plate 5. The triangular plate 7 is driven by the push-pull drive shaft 10 to achieve sealing and locking or separation from the medium delivery channel opened in the valve body 4; Drive and rotate synchronously with the radial direction of the triangular plate 7.

[0082] The outer side of the valve plate 5 is provided with a rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com