Antistatic and anti-tearing grid cloth and preparation method thereof

An anti-tear and anti-static technology, used in fabrics, textiles, textiles and papermaking, etc., can solve the problems of limited application range of anti-static fabrics, poor anti-static effect, etc., to achieve good anti-tear function and low surface resistance , Good anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

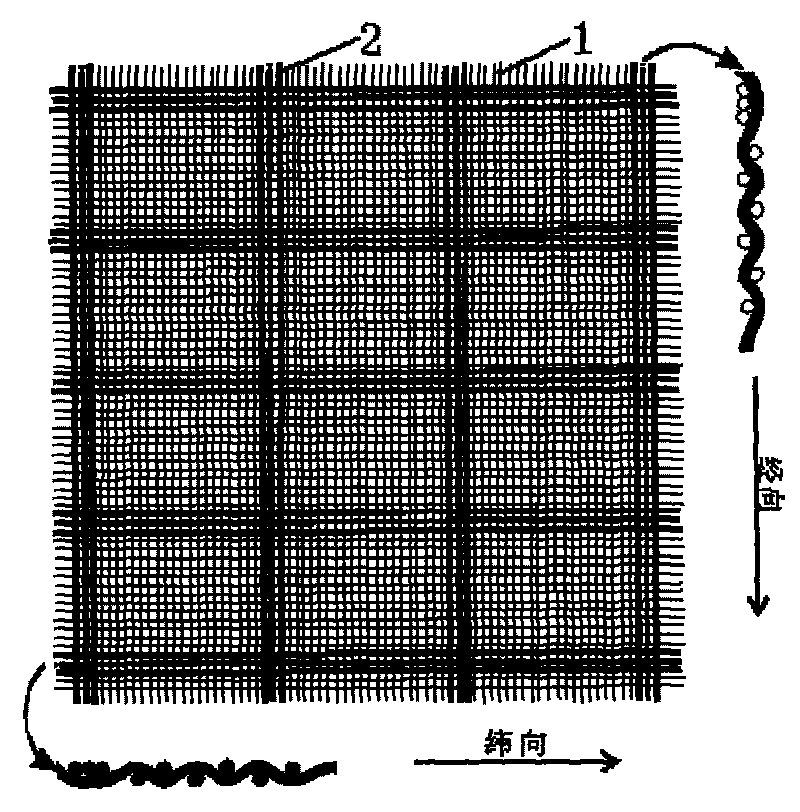

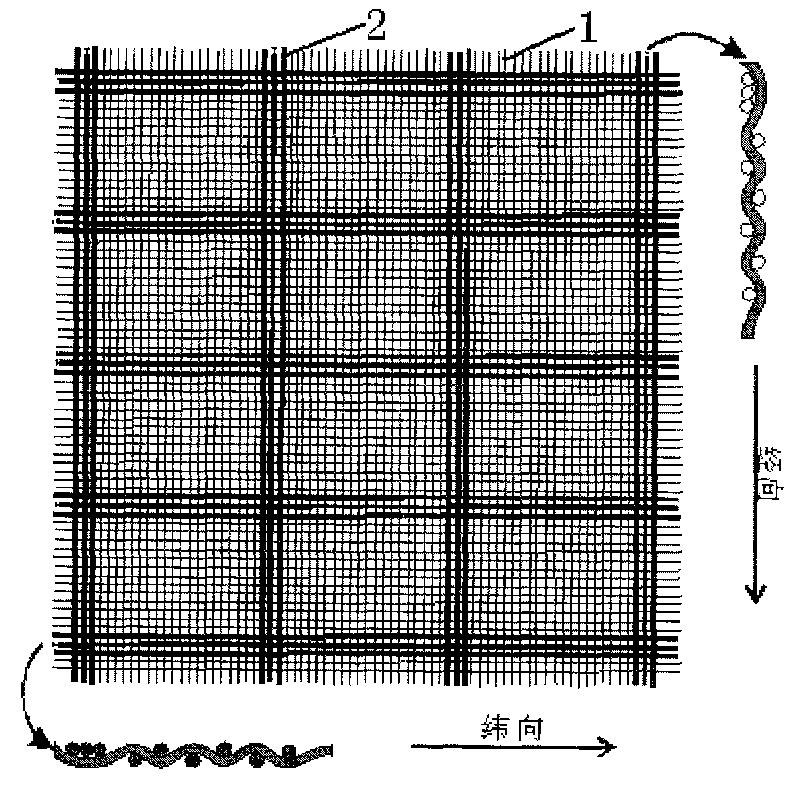

[0038]Select reinforcing ribs 2 containing stainless steel fibers, and set reinforcing ribs 2 along the warp and weft directions of the fabric at intervals of 0.8cm; for warping, the speed of the warping machine is controlled at 700m / min, and the tension is 3480N; for sizing, set the moisture regain is 1%, the sizing rate is 3%, the elongation is 0.3%, the unwinding tension is 570N, the yarn feeding tension is 570N, the pressing pressure is 8KN, the size viscosity is 5s, the vehicle speed is 50m / min, and the wet zone tension is 590N, the tension in the dry zone is 1800N, the temperature of the drying cylinder in the wet zone is 130°C, and the temperature of the drying cylinder in the dry zone is 120°C; draw in the warp, zone the distribution yarn 1 and the reinforcing rib 2, find out the reinforcing rib 2, and then Threading yarn; weaving, acceptance and finishing to obtain anti-static and tear-resistant plaid.

Embodiment 2

[0040] Select reinforcing ribs 2 containing copper fibers, and set reinforcing ribs 2 along the warp and weft directions of the fabric every 1.0cm; for warping, the speed of the warping machine is controlled at 700m / min, and the tension is 3560N; for sizing, set the moisture regain 2%, the sizing rate is 7%, the elongation is 0.6%, the unwinding tension is 600N, the yarn feeding tension is 650N, the sizing pressure is 10KN, the slurry viscosity is 7s, the vehicle speed is 60m / min, and the wet zone tension is 800N, the tension in the dry zone is 2000N, the temperature of the drying cylinder in the wet zone is 132°C, and the temperature of the drying cylinder in the dry zone is 125°C; through the warp, zone the distribution yarn 1 and the reinforcing rib 2, find out the reinforcing rib 2, and then Threading yarn; weaving, acceptance and finishing to obtain anti-static and tear-resistant plaid.

Embodiment 3

[0042] Choose to contain conductive or subconductive fiber reinforcing ribs 2 with nylon as the base material, and the reinforcing ribs 2 are arranged at intervals of 1.2cm along the warp and weft directions of the cloth; warping, the speed of the warping machine is controlled at 700m / min, and the tension is 3560N; for sizing, set the moisture regain rate to 3%, the sizing rate to 11%, the elongation rate to 1%, the unwinding tension to 850N, the yarn feeding tension to 750N, the pressing pressure to 18KN, the size viscosity to 9s, and the machine speed to 70m / min, the tension in the wet zone is 990N, the tension in the dry zone is 2100N, the temperature of the drying cylinder in the wet zone is 135°C, and the temperature in the dry zone is 130°C; draw in the warp, zone the distribution yarn 1 and the reinforcement rib 2, and find out the reinforcement Rib 2, thread the yarn after the separation is correct; weaving, acceptance and finishing, to obtain anti-static and tear-proof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com