Method for preparing polyaniline/manganese dioxide composite material for super capacitor

A supercapacitor, manganese dioxide technology, used in the manufacture of hybrid/electric double layer capacitors, capacitors, electrolytic capacitors, etc., can solve problems such as poor capacitance and cycle stability, limited material conductivity, and high requirements for production equipment, achieving high performance. Specific capacitance, simplified follow-up processing, less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) oxidant potassium permanganate of 0.02mol is dissolved in 100ml water, is made into solution A;

[0035] (2) Dissolve 5ml of aniline monomer in 100ml of 1mol / L hydrochloric acid to form solution B;

[0036] (3) Slowly add solution A to solution B, control the rate of addition, and keep stirring, and react at a constant temperature of 30°C for 6 hours;

[0037] (4) filter the reaction product, and repeatedly wash the product with deionized water and acetone until the filtrate is colorless;

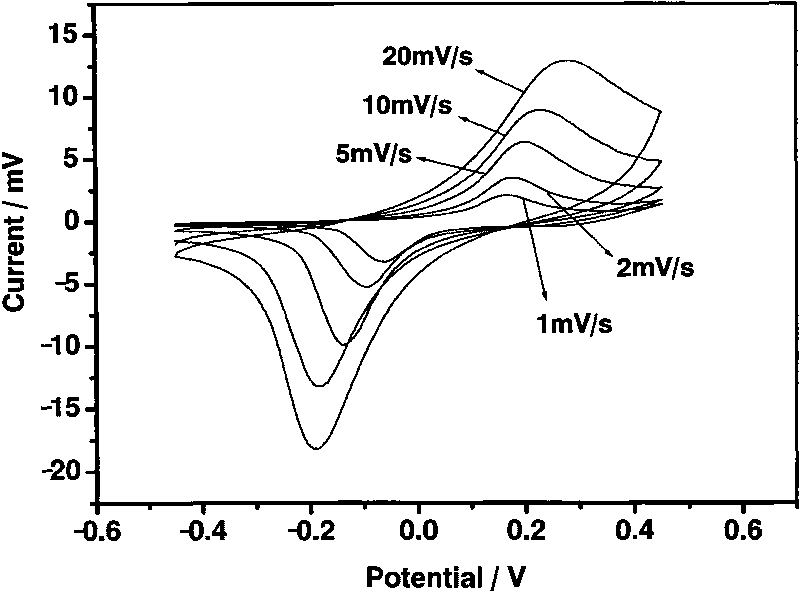

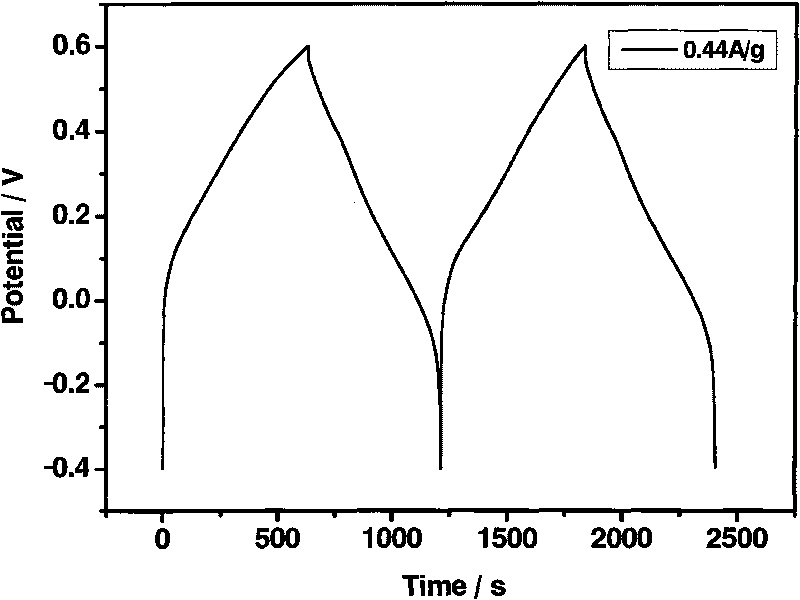

[0038] (5) The washed product was vacuum-dried at 60° C. for 24 h and then ground to obtain a polyaniline / manganese dioxide composite material. It can be calculated that its specific capacitance as a supercapacitor electrode material is 475F / g, and a good cyclic voltammogram ( figure 1 , 2 , 3).

Embodiment 2

[0040] (1) oxidant potassium permanganate of 0.02mol is dissolved in 100ml water, is made into solution A;

[0041] (2) Dissolve 7.47ml of aniline monomer in 100ml of 1mol / L hydrochloric acid to form solution B;

[0042] (3) Slowly add solution A to solution B, control the rate of addition, and keep stirring, and react at a constant temperature of 30°C for 6 hours;

[0043] (4) filter the reaction product, and repeatedly wash the product with deionized water and acetone until the filtrate is colorless;

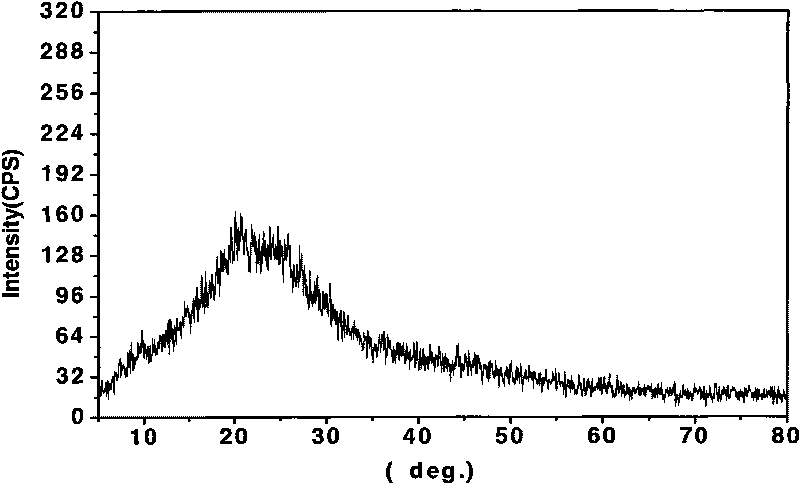

[0044] (5) The washed product was vacuum-dried at 60° C. for 24 h and then ground to obtain a polyaniline / manganese dioxide composite material. XRD test shows that the manganese dioxide in the composite material is amorphous structure.

Embodiment 3

[0046] (1) oxidant potassium permanganate of 0.02mol is dissolved in 100ml water, is made into solution A;

[0047] (2) Dissolve 5ml of aniline monomer in 100ml of 1mol / L hydrochloric acid to form solution B;

[0048] (3) Slowly add solution A to solution B, control the rate of addition, and keep stirring, and react at a constant temperature of 0°C for 6 hours;

[0049] (4) filter the reaction product, and repeatedly wash the product with deionized water and acetone until the filtrate is colorless;

[0050] (5) The washed product was vacuum-dried at 60° C. for 24 h and then ground to obtain a polyaniline / manganese dioxide composite material. The content of manganese dioxide in the composite obtained by chemical analysis is 8.5%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com