Automatic switch-on and switch-off device of overhead line of electric locomotive

A technology of automatic power-on and power-off device, applied in overhead lines, protection against overcurrent, protection against underload or no-load response, etc., can solve safety accidents, labor-intensive, easy to touch and other problems to achieve the effect of preventing safety accidents, avoiding leakage losses, and ensuring safe and reliable power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

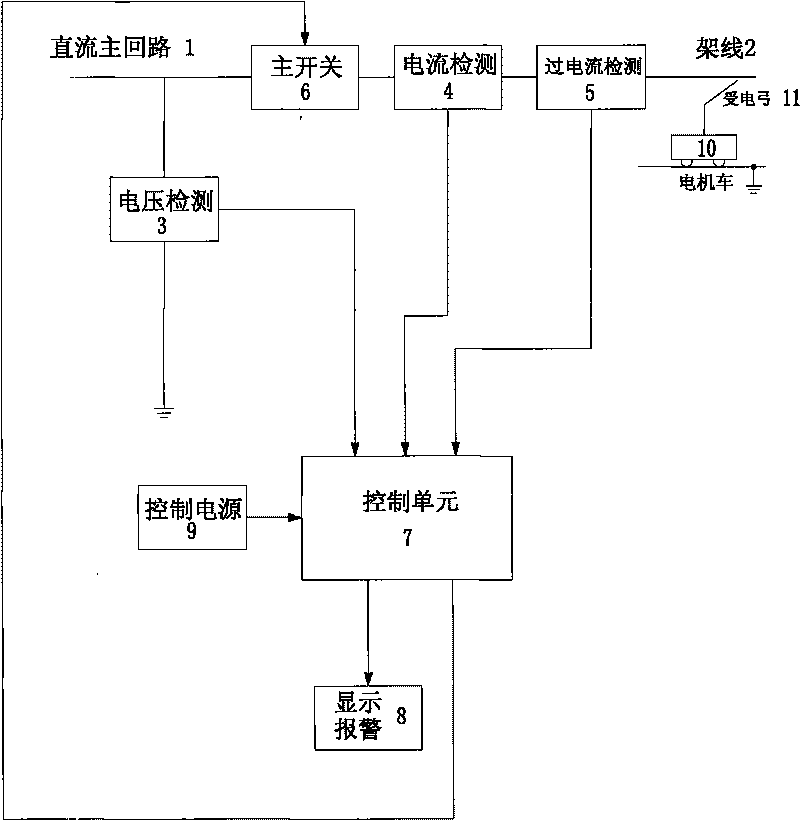

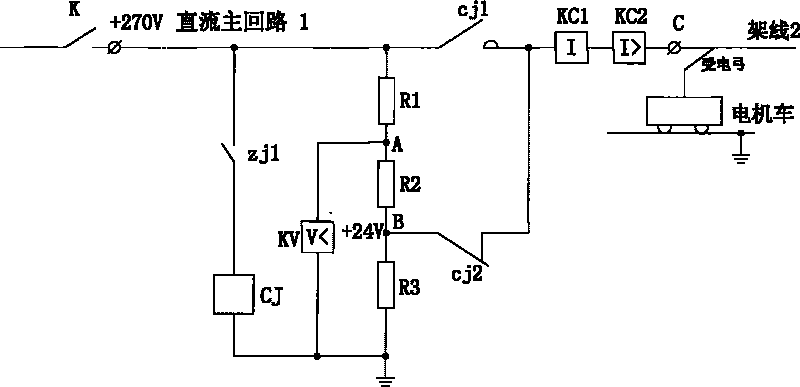

[0017] Example Figure 1-3 Shown: An automatic power-on and power-off device for electric vehicle strung wire, including strung wire 2, DC main circuit 1, voltage detection unit 3, current detection unit 4, over-current detection unit 5, main switch 6, program-controlled Control unit 7 , display alarm unit 8 and control power supply unit 9 . A current detection unit 4, an overcurrent detection unit 5, and a main switch 6 are connected in series on the DC main circuit 1, and a voltage detection unit 3 is connected in series between the input terminal of the DC main circuit 1 and the ground; the voltage detection unit 3, the current detection unit 4. The output end of the overcurrent detection unit 5 is connected to the input end of the control unit 7, the output end of the control unit 7 is respectively connected to the main switch 6 and the display alarm unit 8, and the control power unit 9 is connected to the control unit 7.

[0018] The DC power supply voltage is DC270V, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com