Abrasive wheel saw clamping mechanism

A technology of clamping mechanism and grinding wheel saw, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of large space occupation, and achieve the effect of saving space and good sawing effect

Inactive Publication Date: 2011-01-05

JIANGYIN DONGCHEN MACHINERY MFG

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Before the present invention was made, the conventional grinding wheel saw clamping mechanism was not made on the machine body. When the bar was sawed, the section was not perpendicular to the bar. When the horizontal clamping device of the clamping device was moved out of the roller table, it took up a lot of space.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

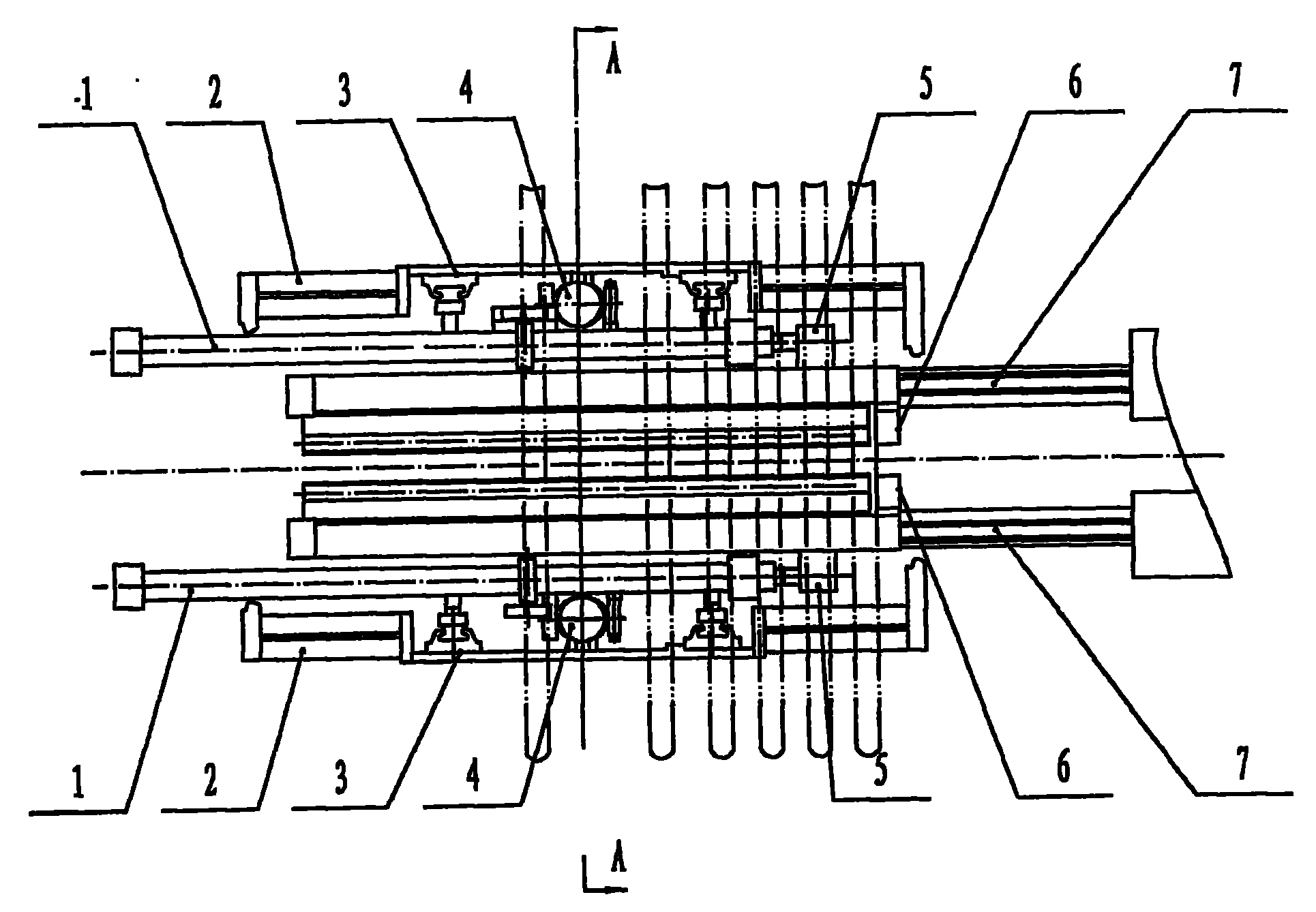

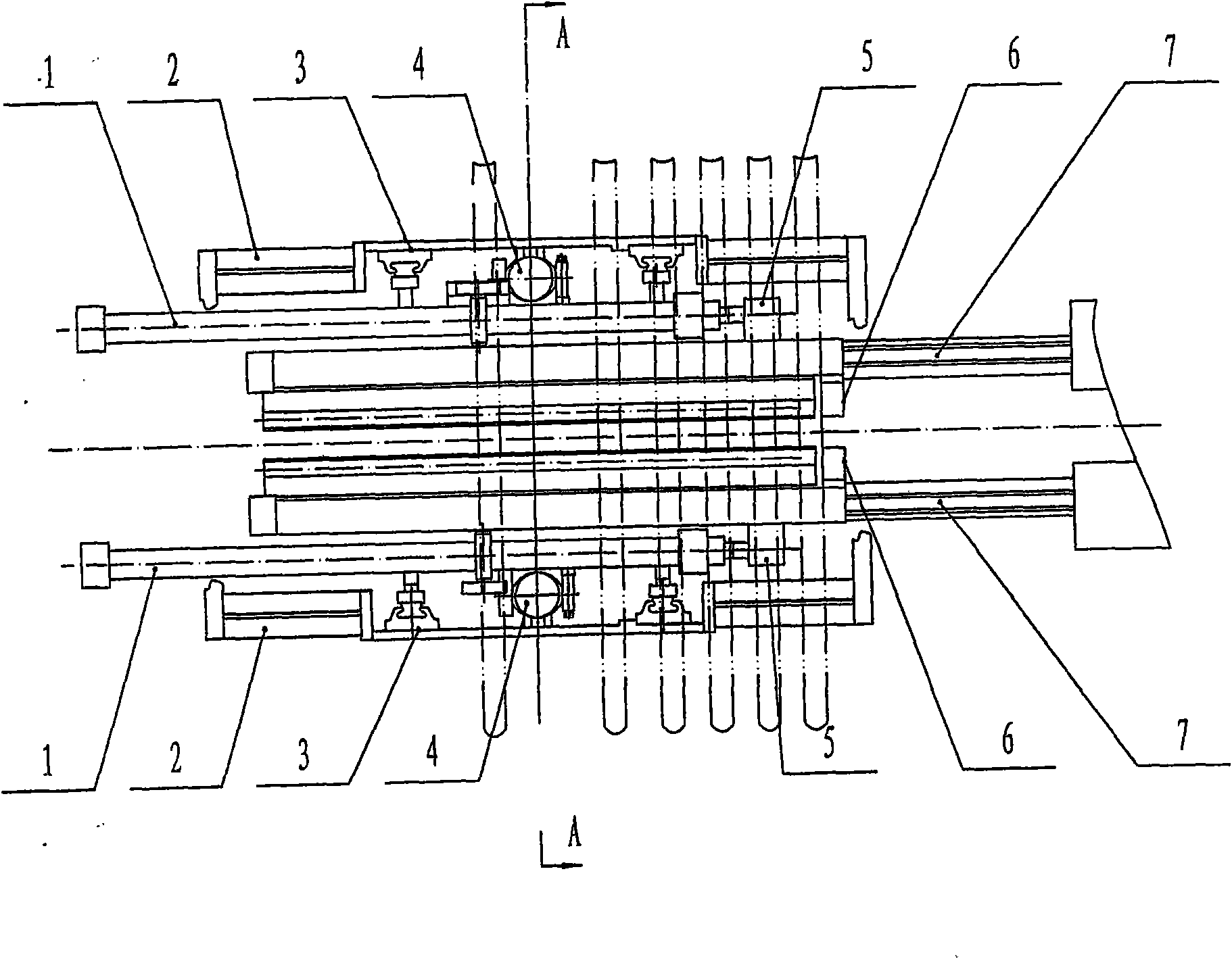

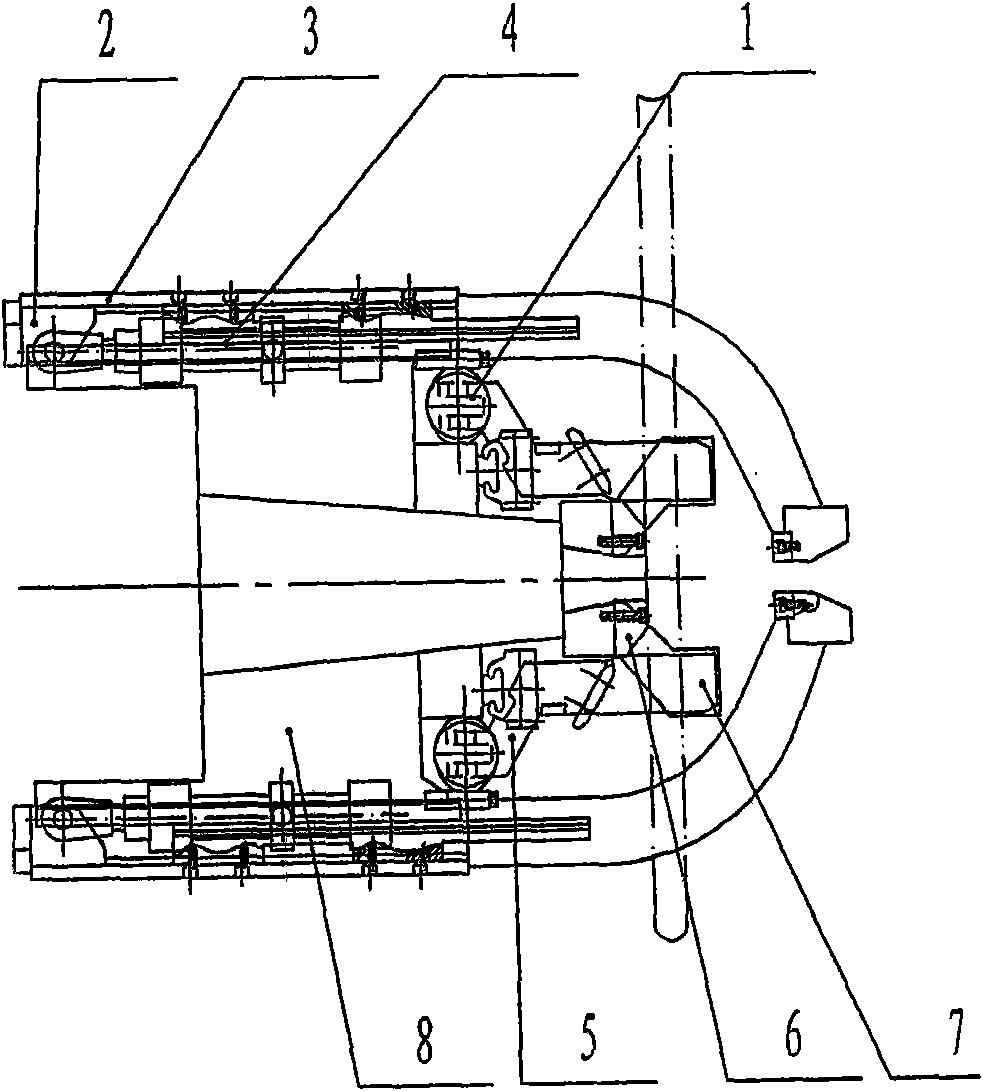

The invention relates to an abrasive wheel saw clamping mechanism which mainly realizes saw cutting and clamping of steel billet. The abrasive wheel saw clamping mechanism comprises a base (8), horizontal clamping oil cylinders (1), horizontal feeding brackets (5), horizontal linear guide rails (7), vertical clamping oil cylinders (4), vertical swaging brackets (2), vertical linear guide rails (3) and two chock blocks (6), wherein the horizontal clamping oil cylinders (1) are arranged the front side and the rear side of the upper part of the base (8); the horizontal linear guild rails (7) arearranged at the front side and the rear side of the upper part of the base (8); the horizontal feeding brackets (5) are arranged on the two horizontal linear guide rails (7), and are respectively articulated with piston rods of the two horizontal clamping oil cylinders (1); the vertical clamping oil cylinders (4) are arranged at both sides of the front and the rear of the lower part of the base (8); the vertical linear guide rails (3) are arranged at the front side and the rear side of the lower part of the base (8); the vertical linear guide rails (3) are arranged at the front side and the rear side of the lower part of the base (8); the vertical swaging brackets (2) are vertically arranged on the two vertical linear guide rails (3), and are respectively articulated with the piston rods of the two vertical clamping oil cylinders (4); and the two chock blocks (6) are respectively arranged on the front part and the rear part and are fixedly arranged at the middle of the top of the base(8). The invention can save space and has good sawing cutting effect.

Description

Grinding wheel saw clamping mechanism (1) Technical field The invention relates to a grinding wheel saw. It mainly realizes sawing and clamping of steel billets. The utility model belongs to the technical field of steel rolling auxiliary equipment. (2) Background technology Bars and profiles must be sawed after coming out of the rolling mill. Generally, shearing machine cutting, metal saw blade sawing or grinding wheel saw blade sawing are used. Using a shearing machine to cut rails with complex sections will cause the sheared section to be compressed and deformed. Therefore, in order to ensure the quality of the cross-section, it is necessary to use a sawing machine to cut off the special-shaped cross-section rolled pieces such as steel pipes and section steel. Compared with the metal saw, the grinding wheel saw can cut steel types of different materials, the vibration of the machine is small, and the sawing surface has the advantages of high finish. With the increas...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B27/06

Inventor 刘成龙

Owner JIANGYIN DONGCHEN MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com