Batching apparatus of wet desulfurization gypsum

A desulfurization gypsum and hopper technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of complex batching device, easy clogging of wet desulfurized gypsum delivery ingredients, etc., achieve accurate batching, eliminate relative stability, and operate handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

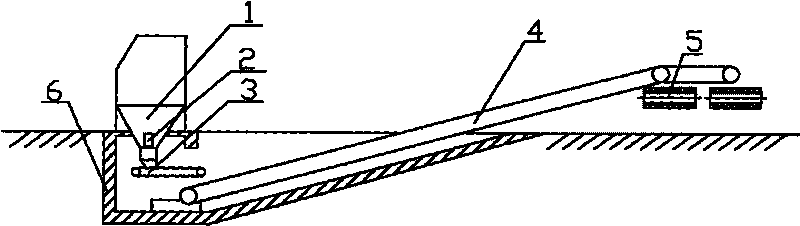

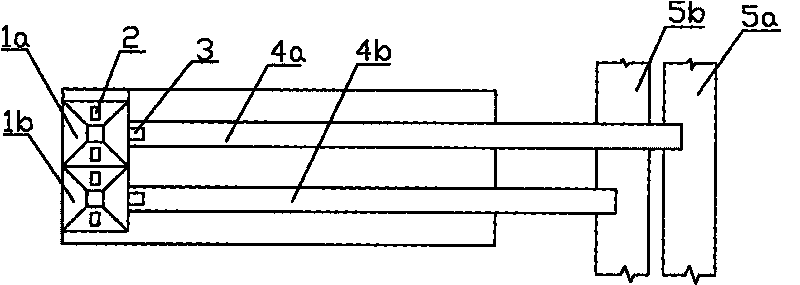

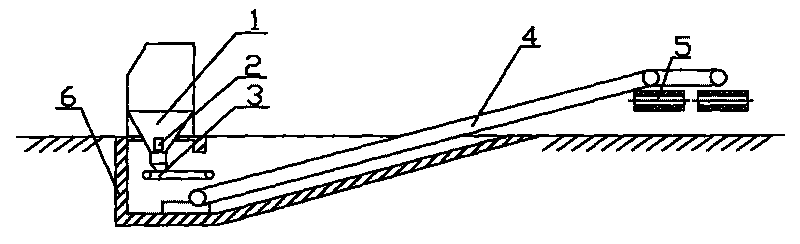

[0014] Such as figure 1 As shown, two hoppers 1 are arranged in the pit 6, the feed inlet at the upper end of each hopper 1 is set above the ground, and the outlet at the lower end is set in the pit 6, and the outlet of each hopper 1 is directly below Belt electronic scale 3 is provided with, belt electronic scale 3 cooperates with one end of the climbing conveyor belt 4 located under it, and the climbing conveyor belt 4 other end is arranged on the top of the main conveyor belt 5 on the ground and cooperates with the main conveyor belt 5. Such as figure 2 As shown, 1a and 1b are identical, and two groups of climbing conveyor belts 4a, 4b cooperate with main conveyor belts 5a and 5b respectively.

[0015] In order to make the transmission smoother, two bin wall vibrators 2 are arranged symmetrically at the outlet of each hopper 1, and the base of the bin wall vibrator is fixed on the outer wall of the outlet of the hopper.

[0016] The number of groups of the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com